As a manufacturer specializing in CNC machining, Nantong Sunway Science and Technology Development Co., Ltd. has demonstrated comprehensive capabilities, from structural component processing to complete machine assembly, through continuous investment in basic manufacturing and technical equipment.

1. What is the basic definition of CNC machining equipment?

CNC machining equipment, or computer numerical control (CNC) machining equipment, is an automated system that precisely controls machine tool operations through computer programs. It utilizes pre-programmed code instructions to perform processes such as material cutting, forming, or assembly. The core of this type of equipment is converting digital signals into mechanical motion, ensuring consistency and controllability during the machining process. As a manufacturer, Nantong Sunway Science and Technology Development Co., Ltd. has demonstrated how digital control can be applied to actual production, thereby improving overall machining efficiency, by introducing advanced guideway grinders and precision machining equipment.

2. What are the main types of CNC equipment?

CNC equipment encompasses a variety of types, including milling machines, lathes, grinders, and drilling machines, each designed for specific machining needs. Milling machines are suitable for machining complex curved surfaces, lathes excel at rotating parts, and grinders are used for high-precision surface grinding. Manufacturers such as Nantong Sunway Science and Technology Development Co., Ltd. have demonstrated how to build a comprehensive machining system by building a large-scale structural parts processing plant that integrates multiple equipment types. This integrated capability ensures a continuous process from roughing to finishing, meeting diverse industrial needs.

3. What are the core advantages of CNC machining?

The core advantages of CNC machining include high precision, high efficiency, and a high level of automation. High precision stems from the repeatability of computer control, resulting in extremely narrow error margins and suitable for precision component manufacturing. High efficiency reduces manual intervention and cycle times in mass production. Automation reduces the risk of human error through program control. Nantong Sunway Science and Technology Development Co., Ltd. has strengthened these advantages in developing its own machining and assembly capabilities, for example, by using precision equipment to ensure the quality of structural parts and ultimately improve the performance of the entire machine.

4. How can manufacturers achieve full-process independent machining capabilities?

Achieving full-process independent machining capabilities requires equipment integration and technology optimization. This includes establishing an in-house foundry to process raw materials, then using a machining plant to refine the structural parts, and finally assembling the complete machine. Nantong Sunway Science and Technology Development Co., Ltd.'s investment strategy demonstrates this, with its high-standard facilities supporting a seamless transition from initial casting to final assembly. This full-process approach reduces external dependencies, improves supply chain resilience, and ensures controlled product quality.

5. What is the key role of CNC equipment in industrial applications?

CNC equipment plays a key role in industry and is widely used in sectors such as aerospace, automotive, and electronics. It supports the production of complex components, such as engine parts or precision molds, to meet tight tolerances. Nantong Sunway Science and Technology Development Co., Ltd.'s practice highlights the importance of equipment in structural parts machining, achieving multi-industry compatibility through advanced systems. This broad applicability stems from the equipment's programmability and flexibility, driving the transformation of manufacturing towards intelligence.

6. What are the future trends in CNC machining equipment?

The future trend of CNC machining equipment focuses on intelligent and integrated development. Intelligence involves AI-assisted optimization of machining paths and enhanced adaptive capabilities. Integration emphasizes connecting equipment to the Internet of Things (IoT) for real-time monitoring and predictive maintenance. Nantong Sunway Science and Technology Development Co., Ltd.'s continued investment in technology and equipment foreshadows this trend, with its advanced equipment supporting a data-driven production model. These innovations will drive the industry towards greater efficiency and sustainability.

VIEW MORE

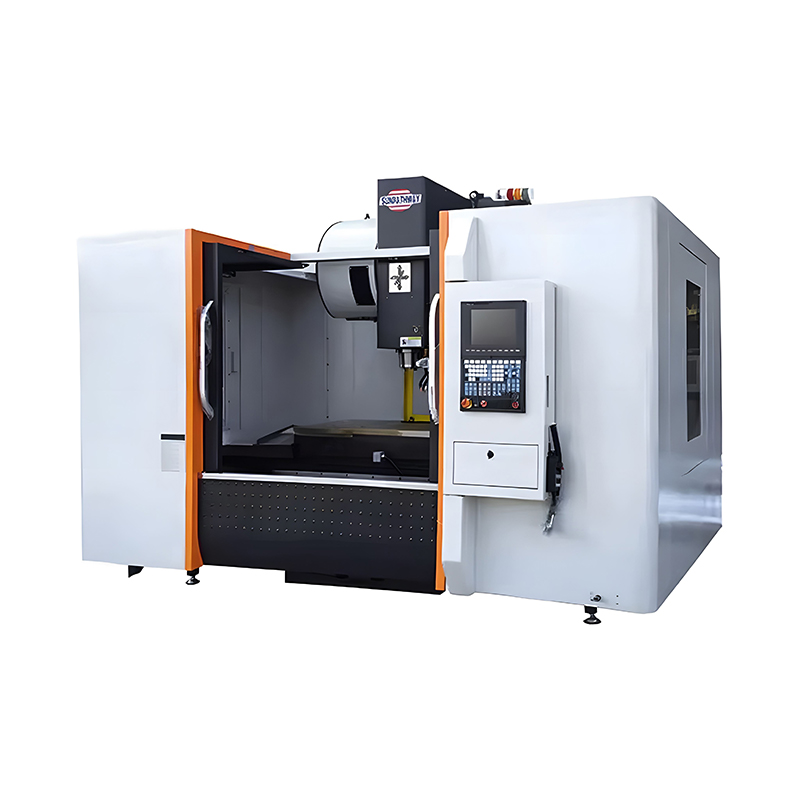

VMC850L High Speed 3 Axis CNC Vertical Machining Center

The VMC850L High-Speed 3-Axis CNC Vertical Machining Center is a high-performance milling machine de...

VIEW MORE

VMC850L High Speed 3 Axis CNC Vertical Machining Center

The VMC850L High-Speed 3-Axis CNC Vertical Machining Center is a high-performance milling machine de...

VIEW MORE

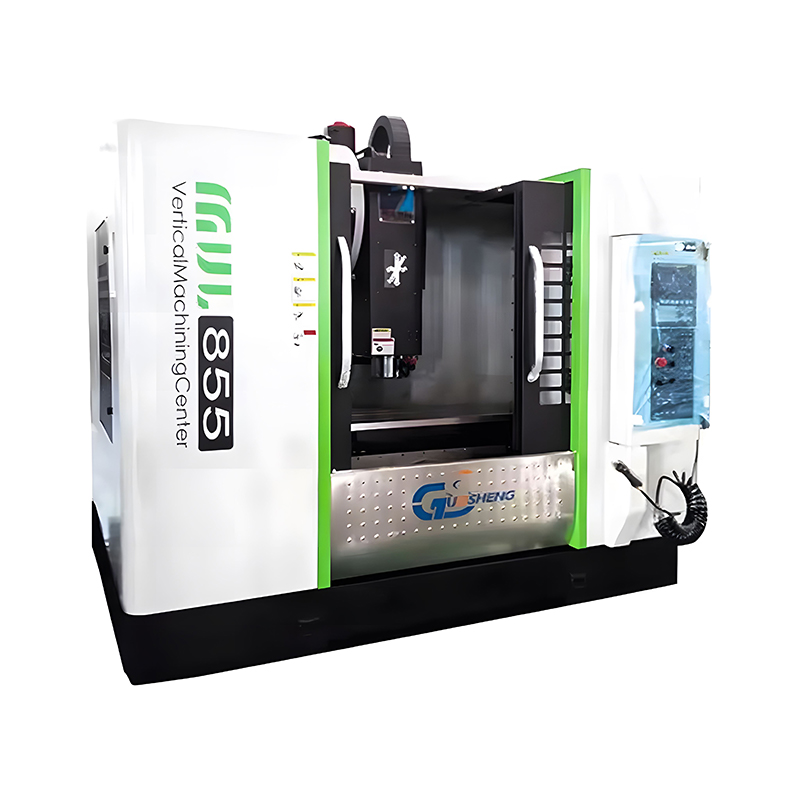

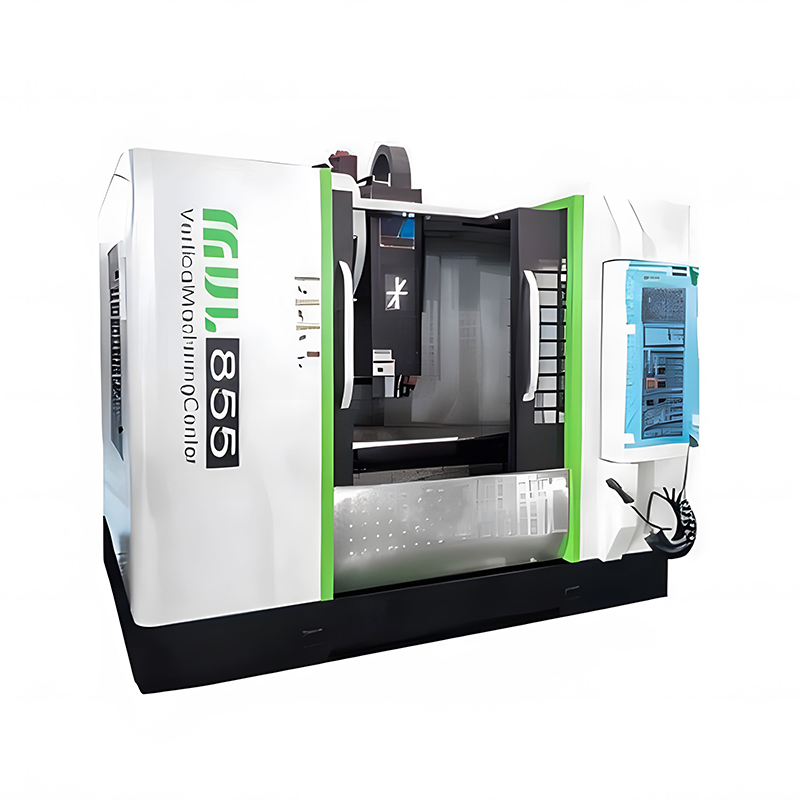

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

VIEW MORE

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

VIEW MORE

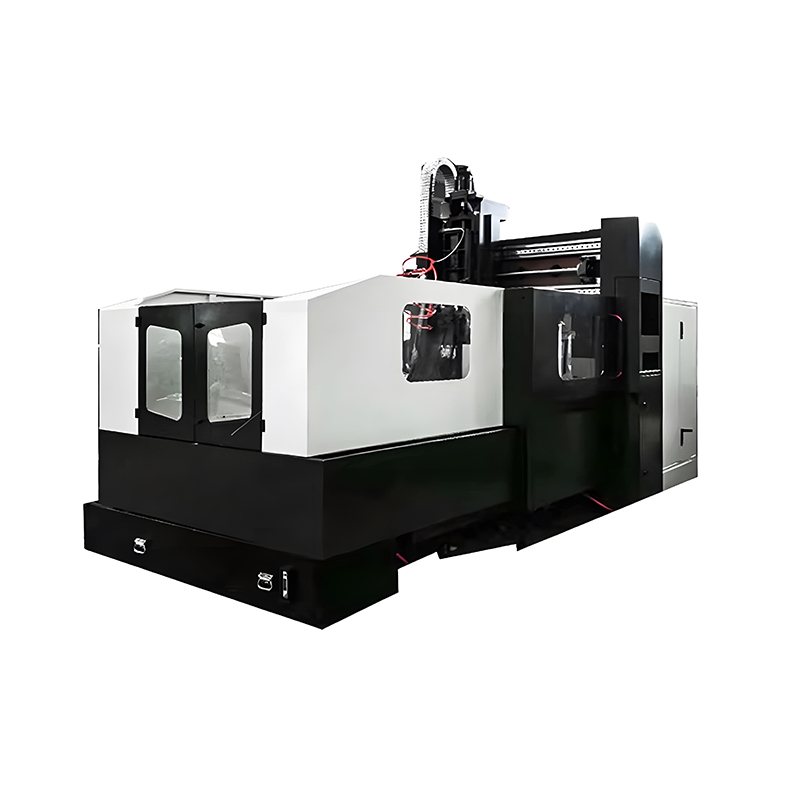

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

VIEW MORE

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

VIEW MORE

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

VIEW MORE

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

VIEW MORE

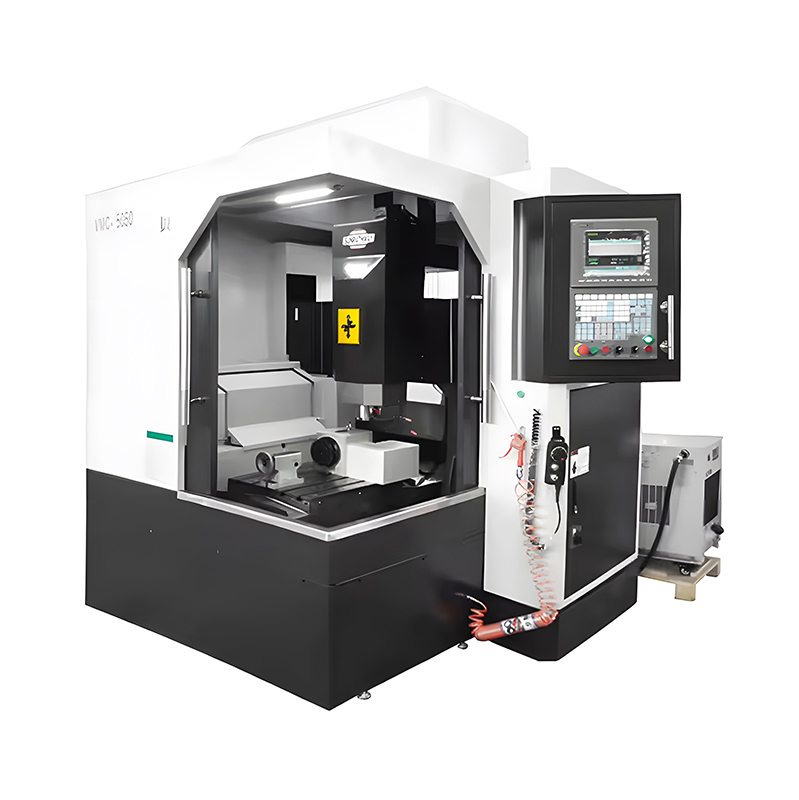

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

VIEW MORE

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

русский

русский Español

Español