Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technologic...

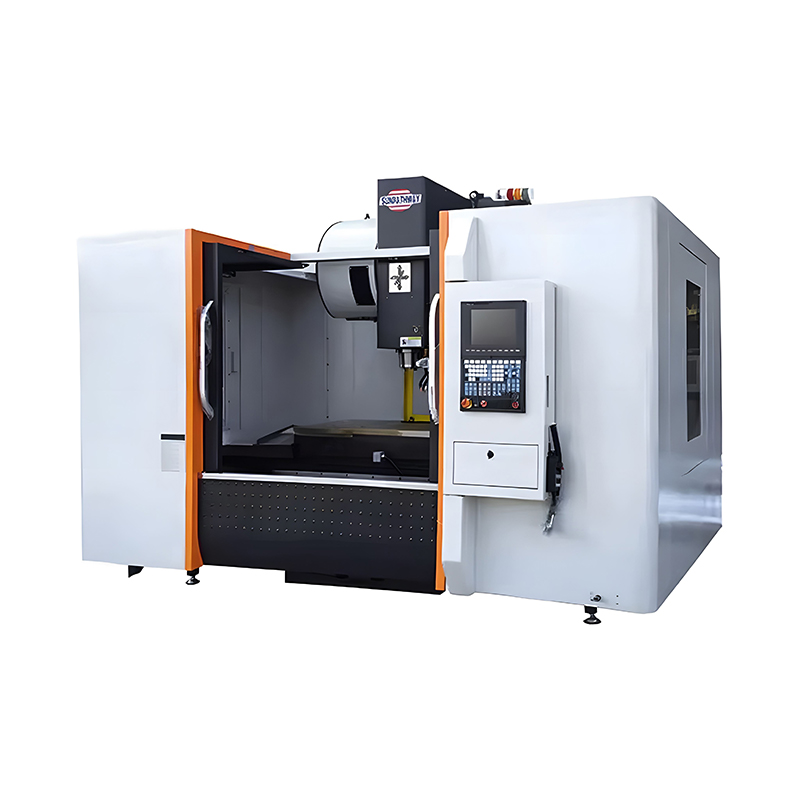

READ MOREVMC850L High Speed 3 Axis CNC Vertical Machining Center

Application scenarios and scope of application

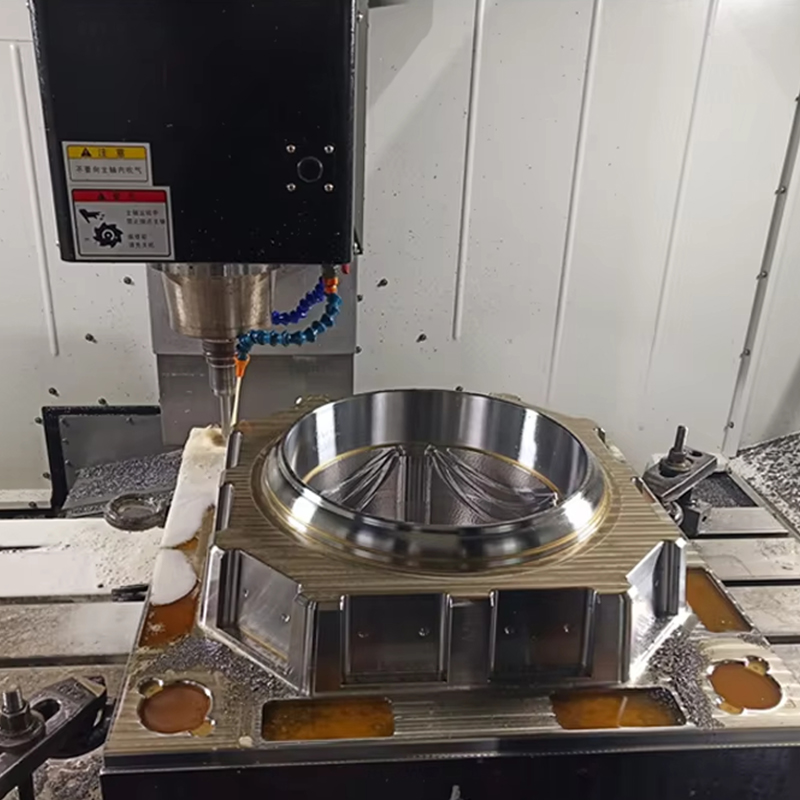

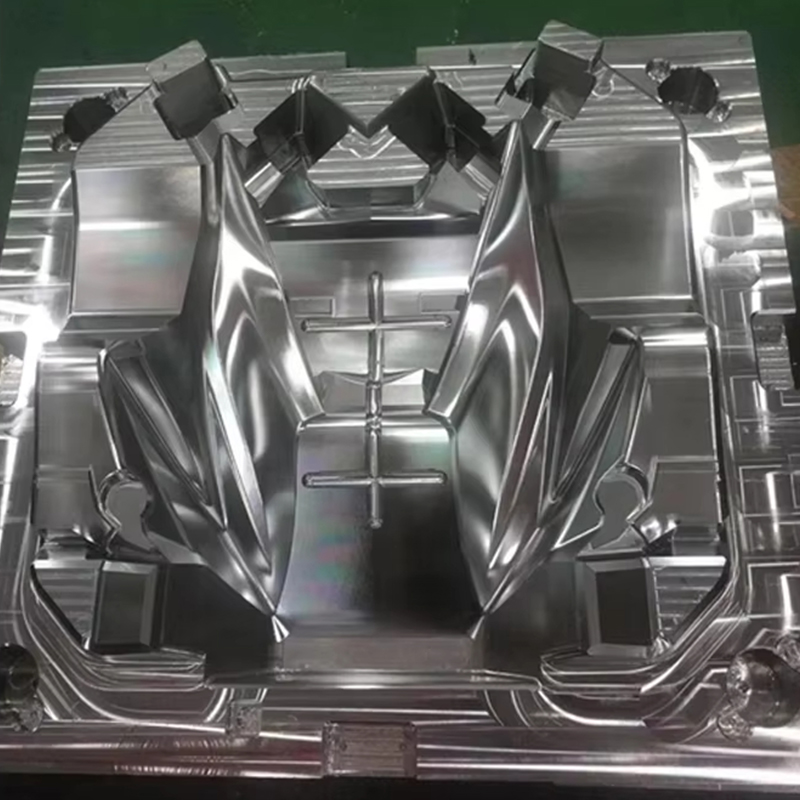

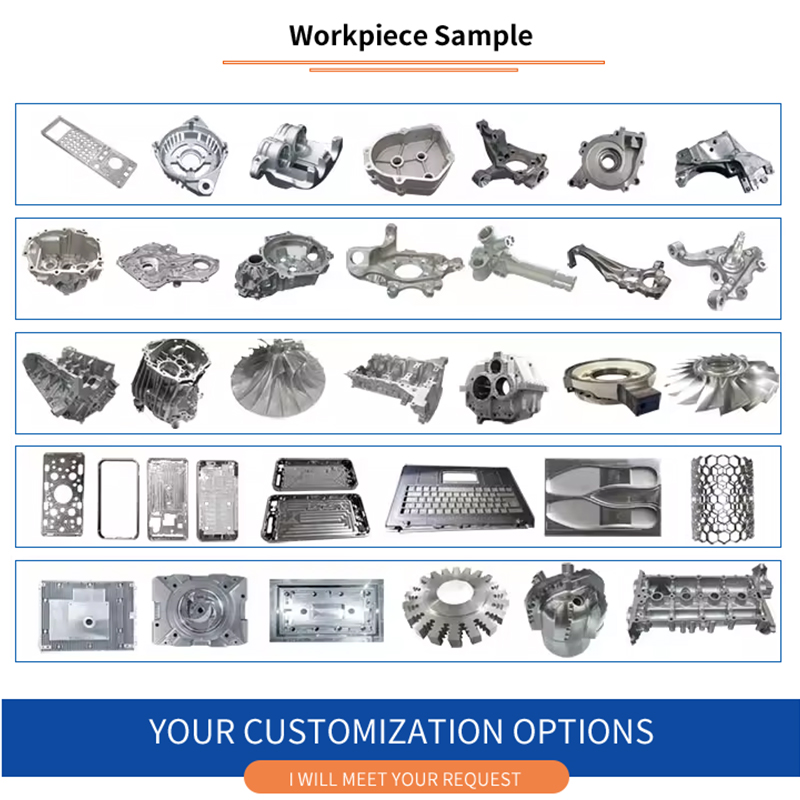

This machining center is widely used in the production of precision components, including engine parts, hydraulic fittings, injection molds, and structural aerospace components. Its versatility allows for efficient processing of various metals, plastics, and composite materials, making it suitable for both small-batch job shops and high-volume manufacturing facilities.

Description

Contact us

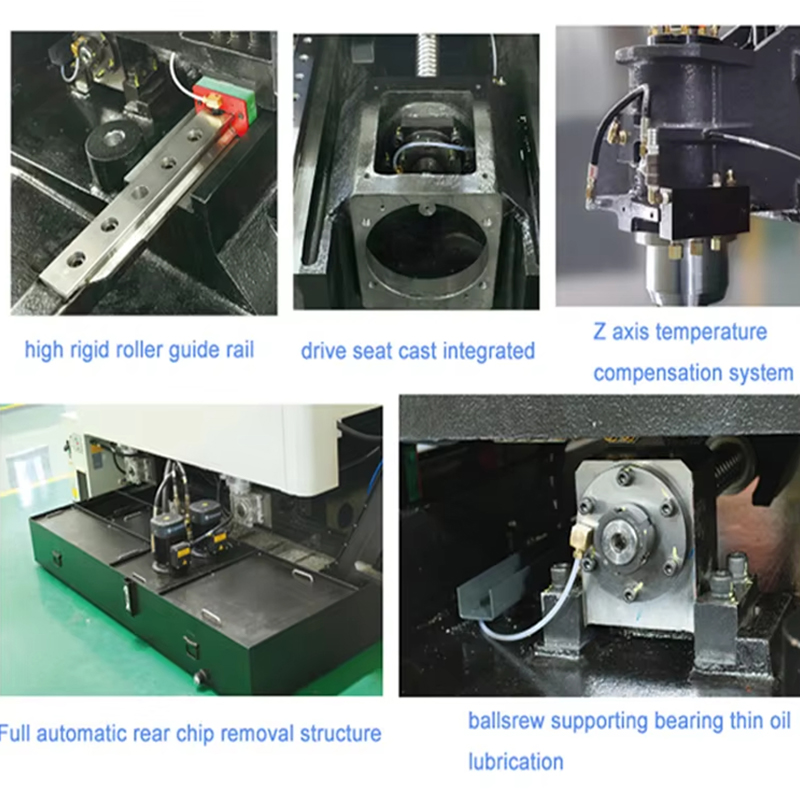

The VMC850L High-Speed 3-Axis CNC Vertical Machining Center is a high-performance milling machine designed for precision metal cutting applications. Built with a heavy-duty cast iron frame and high-rigidity spindle system, it delivers stable machining performance for demanding industrial production. The machine integrates advanced CNC technology, high-speed linear guideways, and efficient chip evacuation to meet tight tolerance requirements.

Product Features/Advantages

Enhanced Dynamic Performance – High-torque servo motors and precision ball screws enable rapid axis movements (X/Y/Z) while maintaining positioning accuracy.

Optimized Cutting Capability – The direct-drive spindle with balanced rotor design minimizes vibration, allowing for higher feed rates and extended tool life.

Space-Efficient Design – Compact footprint with full enclosure maximizes workshop space utilization without compromising work envelope.

Intelligent Process Control – Real-time monitoring of spindle load and axis positioning ensures consistent machining quality.

Flexible Configuration Options – Supports various tooling systems and coolant solutions to adapt to different material processing needs.

Specification

| Machine Type | Unit | VMC850(linear rail) |

| Worktable | ||

| Worktable (length×width) | mm | 1050×500 |

| Maximum load of the table | kg | 650 |

| T-slot (number of slot × slot width × pitch) | mm | 5-18×80 |

| Traversal itinerary | ||

| Travel for X/Y/Z axes | mm | 800/500/800 |

| Distance from spindle nose to table surface | mm | 150-750 |

| Distance from spindle center to column guide surface | mm | 620 |

| Feed system | ||

| CNC system | FANUC-0i MD | |

| Rapid shift of axes X/Y/Z | m/min | 30/30/20 |

| Maximum cutting feed speed | m/min | 12 |

| Automatic tool transform system (CNC milling without) | ||

| Standard tool quantity | bundle | Disc type 24 |

| The largest diameter cutter knife/length | mm | Φ80 Tool/300 |

| Tool changing manner | Air-operated | |

| Average tool exchange time | sec | Disc type: 2.5s |

| Precision | ||

| Positioning accuracy | mm | 0.008 |

| Accuracy of repeated positioning | Mm | 0.005 |

| Spindle system | ||

| Spindle speed | r.p.m | 8000 |

| Spindle specifications (model/installation diameter) | BT40/150 | |

| Drive mode of the spindle | Belt drive | |

| Motor power of the spindle | kw | 11/15 |

| Air pressure | ||

| Requirements for air compressing | Kg/cm² | ≥6 |

| Air pressure flux | m³/min | ≥0.3 |

| Machine specifications | ||

| Integrated weight(kg) | kg | 5000 |

| Overall dimension (weight×width×height) | mm | 2700×2300×2600 |

We can provide you with a satisfactory plan!

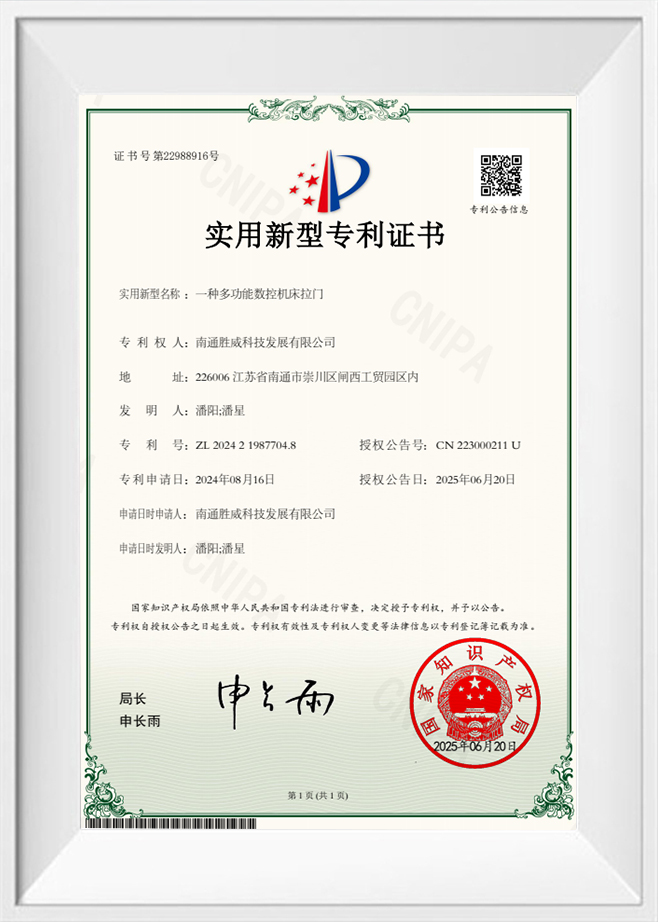

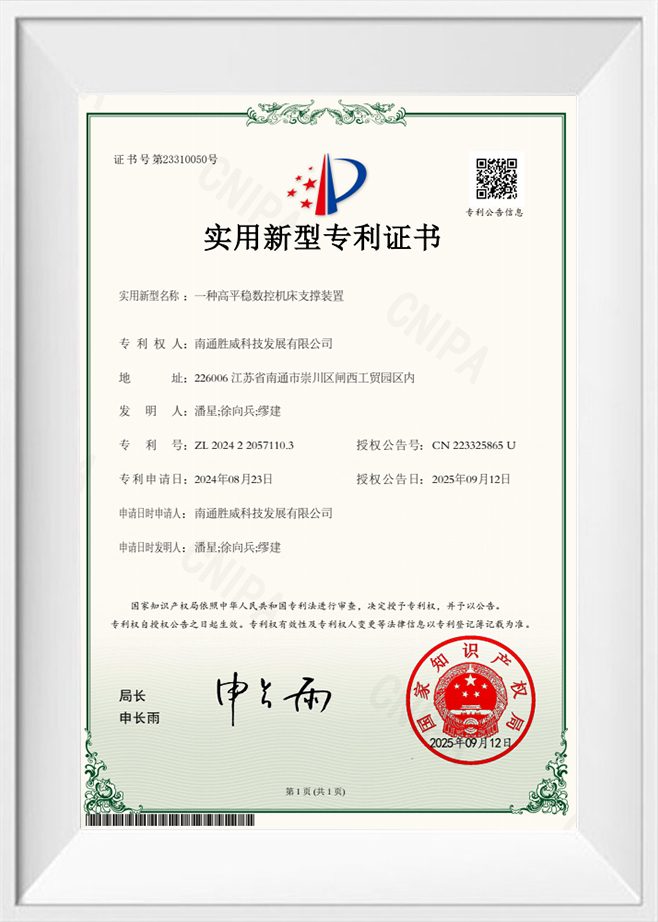

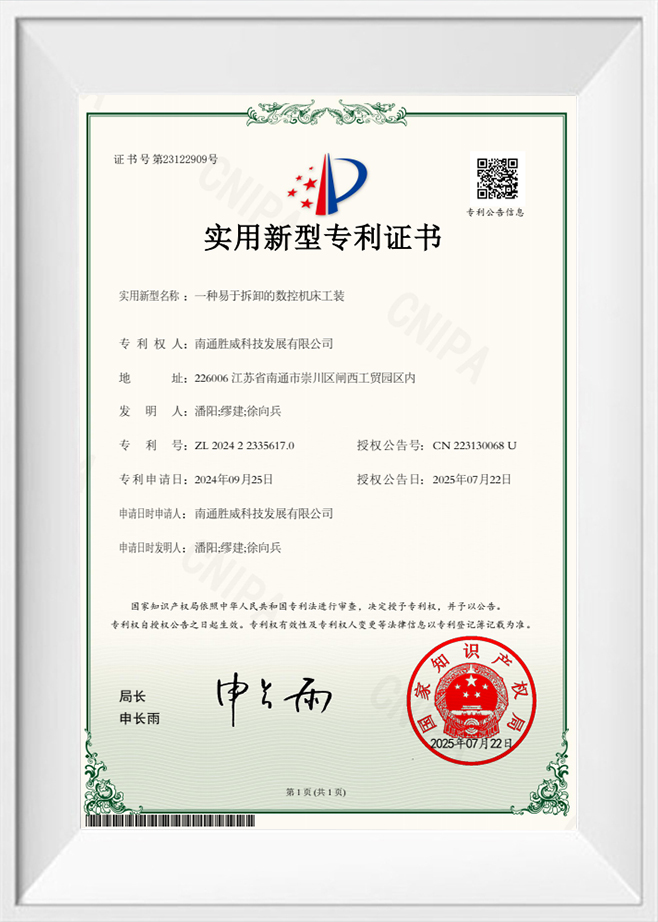

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approache...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vege...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an...

READ MORE

русский

русский Español

Español