Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technologic...

READ MORELM-1814 Gantry Type CNC Milling Machine Controller

Application scenarios and scope of application

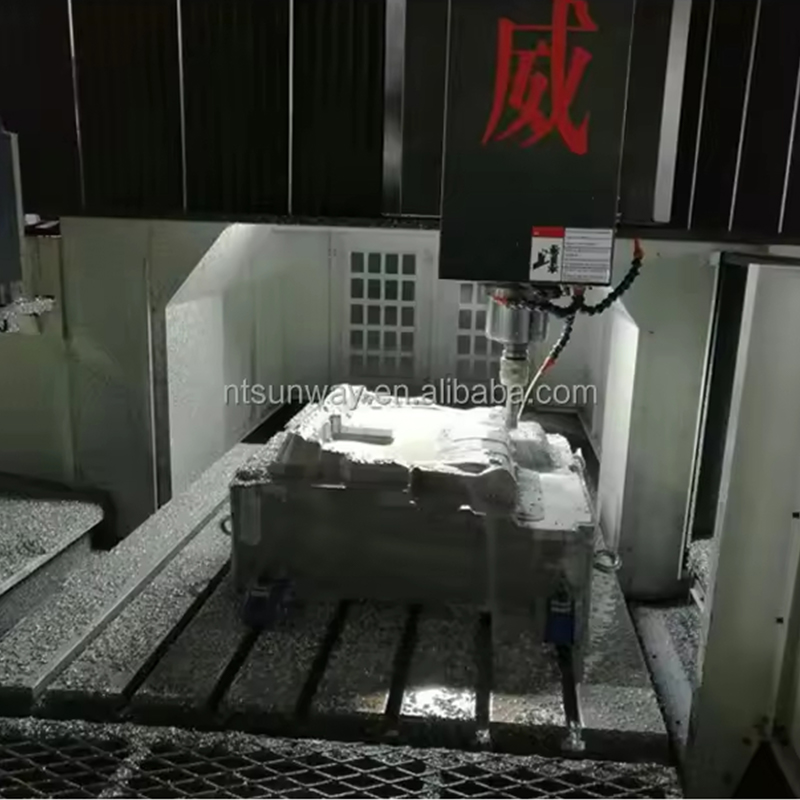

This controller is deployed in industries requiring large-scale material removal, such as structural component fabrication, tool and die production, and heavy equipment manufacturing. It accommodates both ferrous and non-ferrous material processing, with adaptability for custom machining configurations.

Description

Contact us

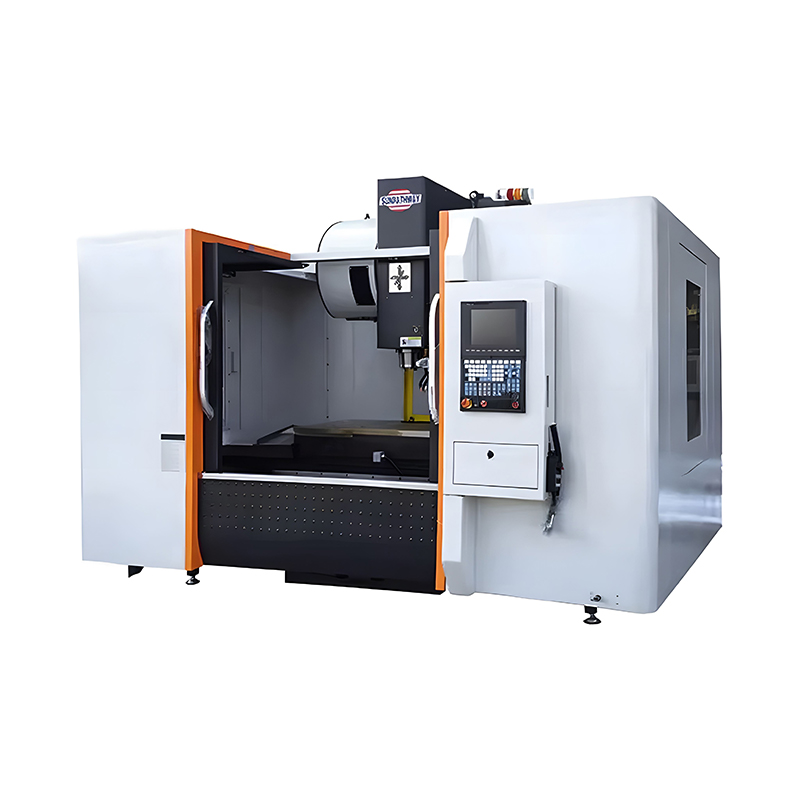

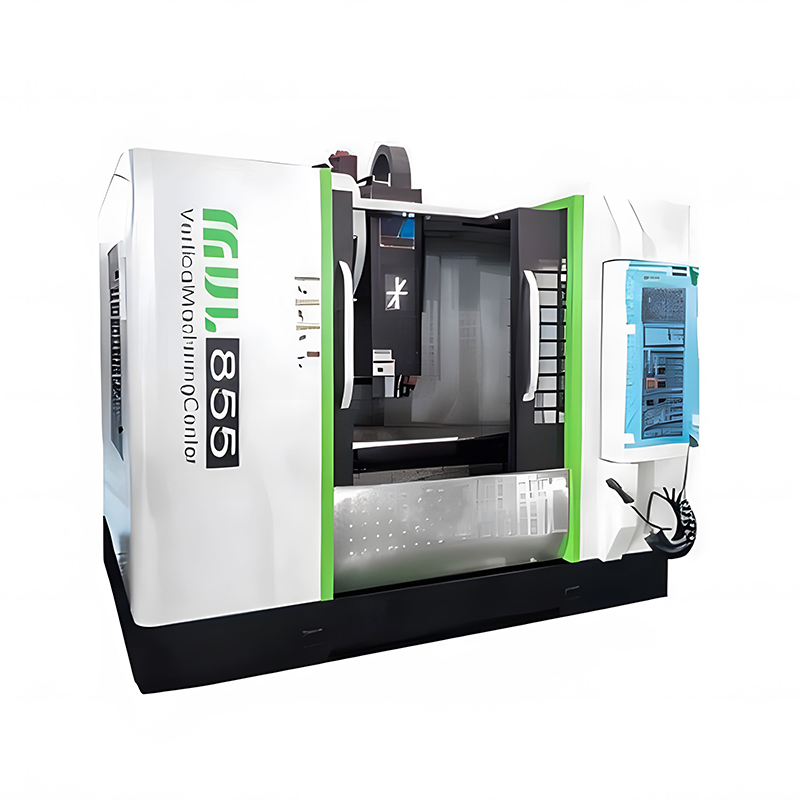

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering precise command execution and stable performance in industrial machining environments. Its architecture is optimized for multi-axis coordination, ensuring consistent operation across extended work cycles.

Product Features/Advantages

Dynamic Processing Capability: Maintains motion stability during high-speed operations and variable load conditions

Configurable Control System: Permits integration of peripheral devices through standardized interface protocols

Operational Efficiency: Reduces setup complexity through parametric programming and toolpath simulation

Environmental Resilience: Designed for continuous operation in environments with electrical interference and particulate exposure

Software Compatibility: Accepts standard G-code formats with support for third-party post-processors

Specification

| model | LM-1090 (Light gantry milling) | LM-1311 (Light gantry milling) | LM1609 (Light gantry milling) | LM-1613 (Light gantry milling) | LM-1813 (Light gantry milling) |

| Workbench area (length × width) (mm) | 1000×750 | 1060×800 | 1300×1000 | 1600×800 | 1800×1200 |

| T-slot number (mm) | 5-14 | 5-18 | 5-18 | 7-18 | 7-22 |

| Spindle speed (r/min) | 3000~ 24000/21000 | 3000~24000/18000 | 3000~24000/18000 | 8000/15000 | 8000/15000 |

| Spindle output power (KW) | 3.2 | 3.2/4 | 4/5.5 | 4/5.5/7.5 | 15 |

| Spindle (Tool diameter range circumference) | φ3-φ12 | φ3-φ12 | φ3-φ12 | φ3-φ12/16 | φ150 BT40 servo |

| Three-axis travel (X*Y*Z axis) (mm) | Three-axis travel (X*Y*Z axis) (mm) | 450×400×200 | 500×500×250 | 600×600×250 | 1300×1800×700 |

| Minimum distance from spindle to table (mm) | 1300×1800×700 | Minimum distance from spindle to table (mm) | 30 | 60 | 150 |

| Gantry passage height (mm) | 150 | 150 | Gantry passage height (mm) | 230 | 850 |

We can provide you with a satisfactory plan!

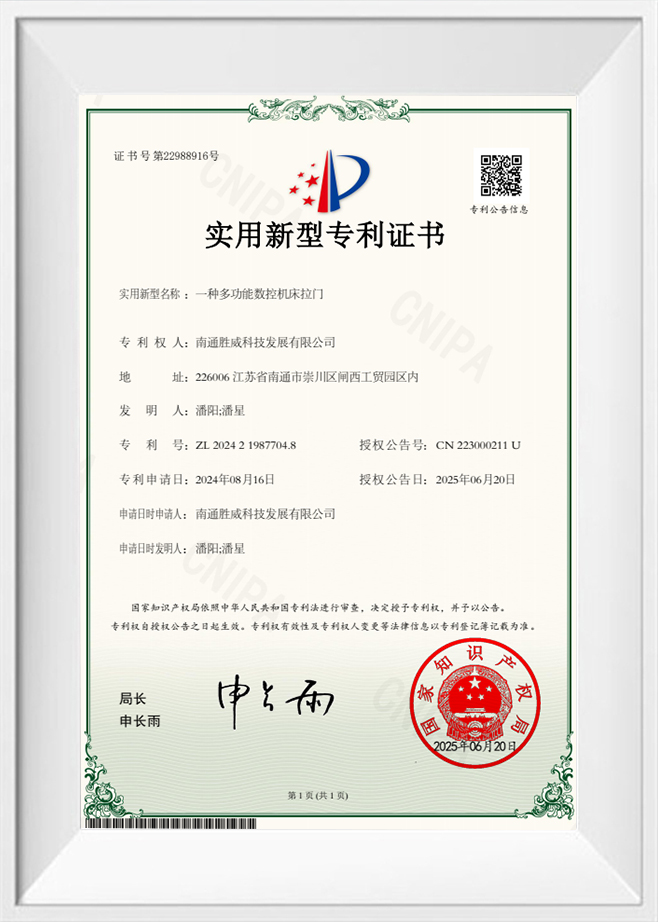

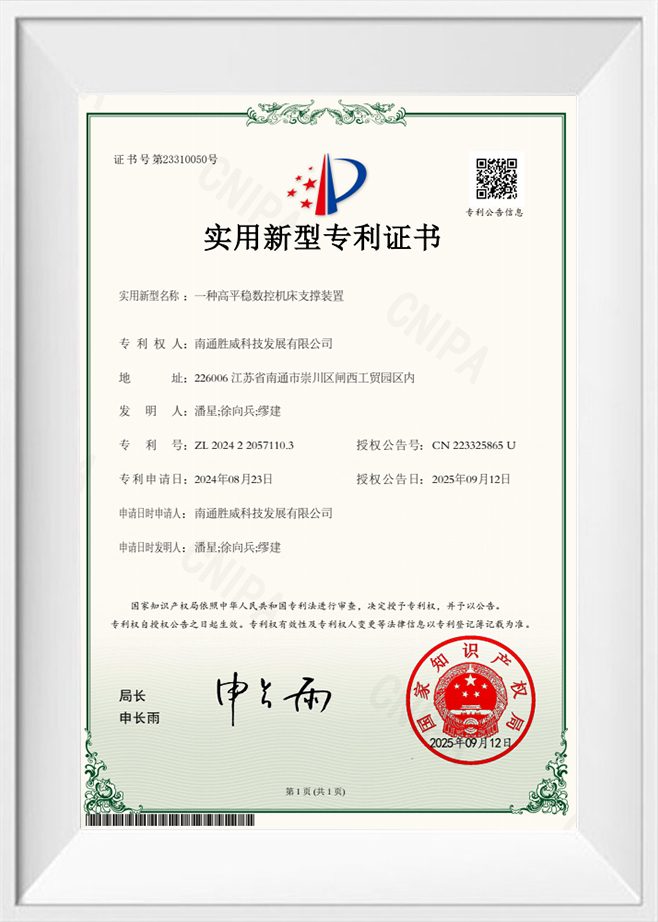

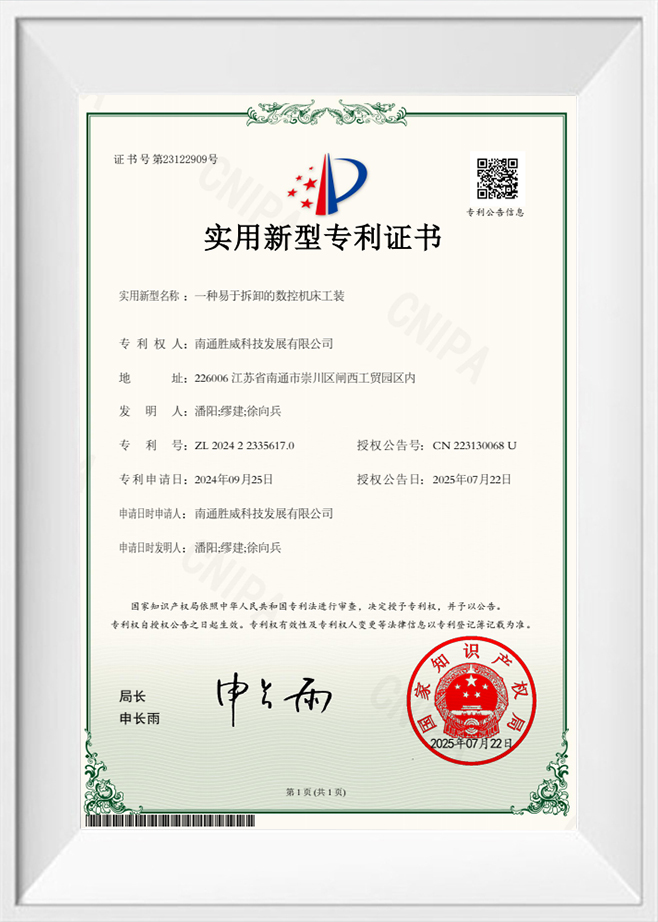

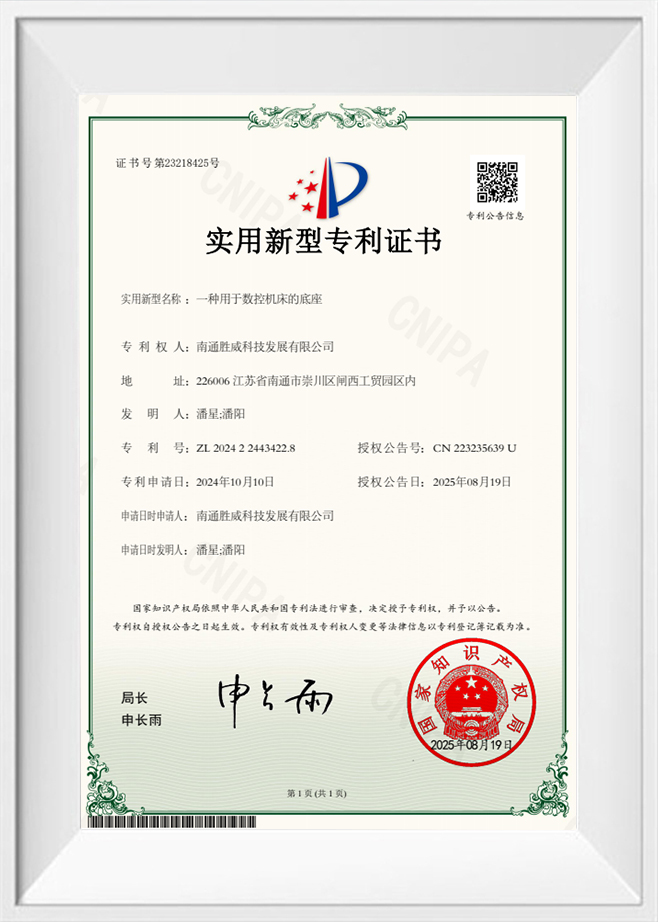

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approache...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vege...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an...

READ MORE

русский

русский Español

Español