The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MOREWe provide quality products and services to customers from all over the world.

Content

- 1 The Core Distinction Between Vertical and Horizontal Machining

- 2 Understanding Vertical Machining Centers (VMC)

- 3 Exploring Horizontal Machining Centers (HMC)

- 4 Direct Comparison: VMC vs. HMC

- 5 Productivity and Throughput Factors

- 6 Cost Analysis and ROI

- 7 Space Constraints and Shop Floor Layout

- 8 Final Verdict: Which Direction Should You Take?

What is the difference between vertical and horizontal machining?

The Core Distinction Between Vertical and Horizontal Machining

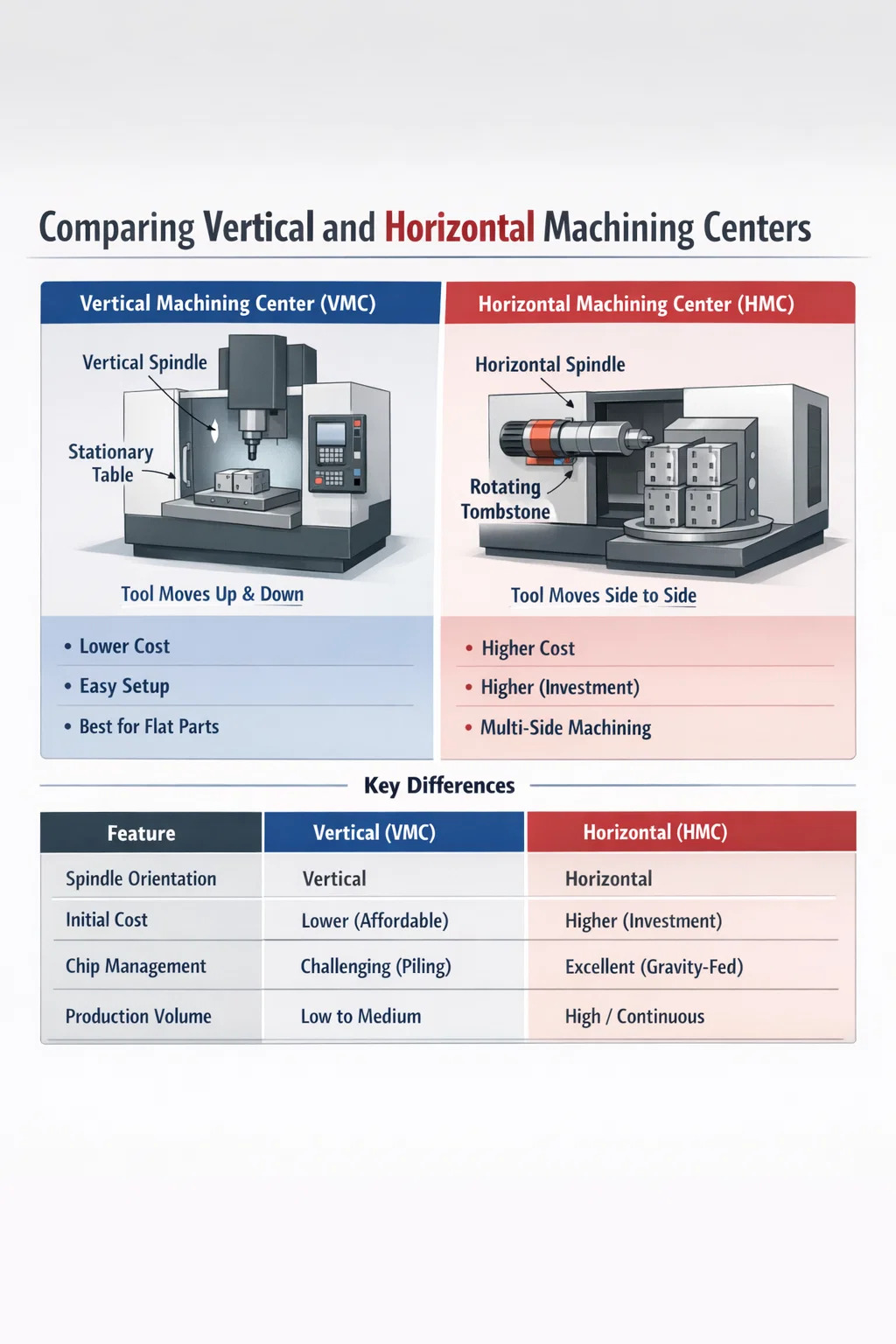

The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the workpiece. In vertical machining centers (VMC), the spindle is oriented vertically, meaning the tool moves up and down on the Z-axis to cut the top of the material. Conversely, in horizontal machining centers (HMC), the spindle is oriented horizontally, allowing the tool to move side-to-side and cut the lateral faces of the part.

This structural difference leads to significant variations in chip evacuation, part capacity, and overall cost. While VMCs are more common due to their lower initial investment and ease of setup, HMCs excel in high-volume production and complex, multi-sided machining tasks.

Understanding Vertical Machining Centers (VMC)

Structural Design and Accessibility

A VMC typically features a stationary table where the workpiece is clamped, while the spindle moves along the X, Y, and Z axes. Because the spindle is vertical, the operator has a clear line of sight to the cutting action. This makes it much easier to set up jobs, adjust offsets, and monitor the process for errors.

Ideal Use Cases for VMCs

- Machining large, flat plates or parts that require heavy work on a single face.

- Prototyping and short-run production where quick setup is vital.

- Operations like milling, drilling, and boring on a single plane.

For example, a shop producing flat engine brackets or simple aluminum housings will almost always prefer a VMC because the clamping is straightforward and the tooling costs are generally lower.

Exploring Horizontal Machining Centers (HMC)

The Integrated Pallet System

HMCs often come equipped with an integrated pallet changer. While the machine is cutting a part on one pallet, the operator can load the next part on a second pallet. This drastically reduces downtime and increases spindle utilization rates, often pushing them above 85% efficiency compared to the 60-70% typically seen on VMCs.

Superior Chip Evacuation

In a horizontal setup, gravity works with the machine rather than against it. As the tool cuts the side of the part, the metal chips fall directly away from the workpiece and into the chip conveyor. This prevents "re-cutting" chips, which can damage the surface finish and prematurely wear out expensive carbide end mills.

Direct Comparison: VMC vs. HMC

Choosing between these two types of CNC machines requires an analysis of your production goals, available space, and budget. The table below outlines the primary differences.

| Feature | Vertical (VMC) | Horizontal (HMC) |

|---|---|---|

| Spindle Orientation | Vertical | Horizontal |

| Initial Cost | Lower (Affordable) | Higher (Investment) |

| Chip Management | Challenging (Piling) | Excellent (Gravity-fed) |

| Production Volume | Low to Medium | High / Continuous |

| Complexity | Simple Setup | Requires Tombstones/Fixturing |

Productivity and Throughput Factors

When considering vertical machining centers, you must account for the time spent on "Part Flips." If a part has features on four sides, a VMC requires four separate setups. Each setup introduces the risk of human error and increases the total time the part sits on the machine.

An HMC, however, often uses a tombstone fixture. This is a large rectangular block mounted on the rotary table. Multiple parts can be clamped to each face of the tombstone. As the table rotates, the spindle can access three or even four sides of every part without an operator ever touching the workpiece. This makes horizontal machining 3 to 4 times more productive for complex, multi-sided components like gearbox housings or manifold blocks.

Cost Analysis and ROI

Initial Investment vs. Long-term Gain

It is no secret that an HMC can cost double or triple the price of a standard VMC. For a small job shop, the $100,000 to $150,000 price tag of a quality VMC is manageable. An HMC might start at $350,000 or more. However, the return on investment (ROI) comes from labor savings. Since one operator can often manage multiple HMCs due to the automated pallet systems, the cost per part drops significantly in high-volume scenarios.

Tooling and Maintenance

Vertical machining centers generally use standard, less expensive workholding like vises. Horizontal machines require specialized tombstones and more complex fixturing, which adds to the upfront project cost. Maintenance for HMCs is also typically more involved due to the complexity of the pallet changers and rotary axes.

Space Constraints and Shop Floor Layout

VMCs have a much smaller footprint. If shop floor space is at a premium, you can fit two or three VMCs in the same square footage required for one large HMC with a pallet pool. This allows for more diverse capabilities if you are running many different small jobs simultaneously.

On the other hand, if you are looking to scale up a specific product line, the "lights-out" capability of a horizontal machine justifies the extra space. Some HMCs can be linked into Flexible Manufacturing Systems (FMS), where a robotic rail system moves pallets between multiple machines and storage stations, allowing for unmanned production through the night.

Final Verdict: Which Direction Should You Take?

The decision is rarely about which machine is "better" in an absolute sense, but rather which is better for your specific workflow. If you are a hobbyist, a prototype developer, or a shop that handles a massive variety of simple parts, vertical machining centers offer the versatility and ease of use you need. They are the workhorses of the modern machine shop for a reason.

If your business is growing and you find yourself struggling with labor costs or losing time to constant part setups, moving to horizontal machining is the logical next step. The ability to clear chips efficiently and cut multiple faces in a single cycle will provide a competitive edge that a vertical machine simply cannot match.

Interested in cooperation or have questions?

-

-

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE -

For many manufacturers, a CNC machine is not just a tool, but an asset with amortization costs over many years. Its lifespan isn't a fixed date, but rather depends on how you "treat" it. Here are some key dimensions that determi...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español