Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MOREWe provide quality products and services to customers from all over the world.

What is the lifespan of a cnc machine?

For many manufacturers, a CNC machine is not just a tool, but an asset with amortization costs over many years. Its lifespan isn't a fixed date, but rather depends on how you "treat" it.

Here are some key dimensions that determine the lifespan of a CNC machine:

1. The Machine's "Base" (Inherent Characteristics)

Casting Quality: Machines with beds made of heavy-duty cast iron are inherently more durable than those welded from thin steel plates. Cast iron not only absorbs vibrations but also deforms very little over time.

Core Components: The grade of the lead screw, guideways, and spindle determines the machine's fatigue limit. High-quality components maintain their initial accuracy even after millions of reciprocating cycles.

2. Workload and Intensity (Usage Habits)

Machining Materials: If you use it all day to cut carbide or high-hardness steel, the impact and wear on the machine will obviously be much greater than when machining wood or aluminum.

Operating Time: Machines that operate for only 8 hours a day typically have a much longer lifespan than machines that run 24/7 in factories. Prolonged full-load or even overload operation accelerates the aging of electronic components and mechanical parts.

3. Maintenance is Key to Longevity

Lubrication System: This is the lifeblood of a CNC machine. Proper lubrication minimizes friction between metal parts. Even a few hours of interrupted lubrication can cause permanent damage to precision tracks.

Cleaning: Metal shavings and coolant are corrosive. If they accumulate in hard-to-reach areas, they can erode seals and even seep into the motor. Developing a habit of cleaning before the end of each workday can extend the machine's lifespan by several years.

4. Environmental and Climatic Influences

Temperature and Humidity Control: Precision CNC machines are highly sensitive to temperature. Sudden temperature changes cause metal to expand and contract, affecting precision; excessive humidity can cause electronic circuit boards to short-circuit or rust.

Power Stability: Frequent voltage fluctuations or sudden power outages are killers for electronic control systems. Installing a voltage regulator can effectively protect the machine's "brain."

5. Technological "Opposition" Rather Than "Breakdown"

Software and Control: Sometimes the mechanical parts of a machine are still functional, but its control system is no longer compatible with new design software, or replacement electronic components are unavailable.

Precision Degradation: After a long period of use, a machine may still operate, but the products it produces may no longer be as precise. For jobs requiring extreme precision, it may have reached the end of its lifespan, but for rough machining, it might still be able to operate for another ten years.

Interested in cooperation or have questions?

-

-

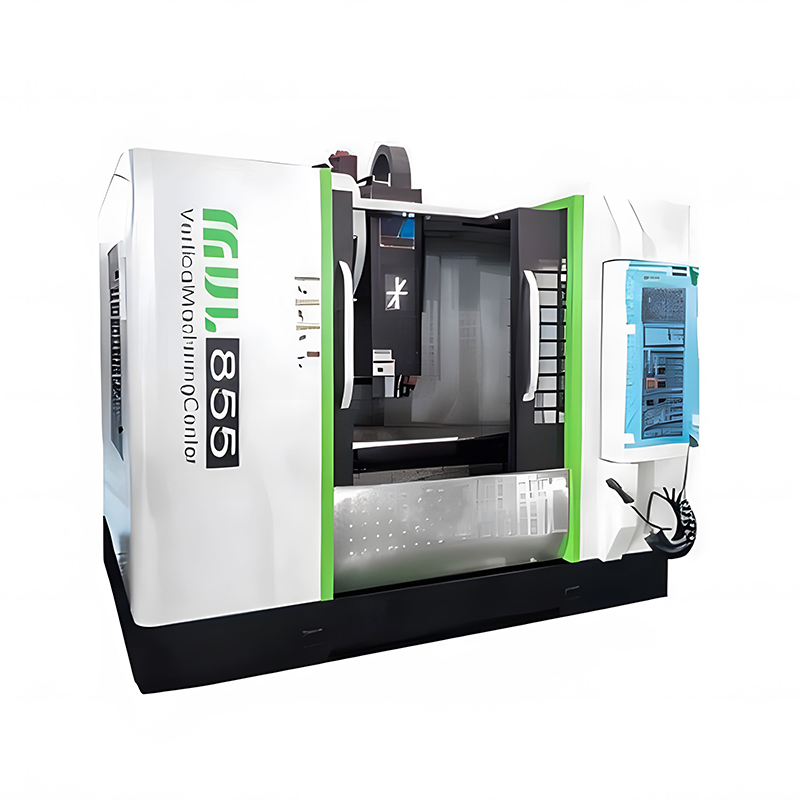

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE -

For many manufacturers, a CNC machine is not just a tool, but an asset with amortization costs over many years. Its lifespan isn't a fixed date, but rather depends on how you "treat" it. Here are some key dimensions that determi...

READ MORE -

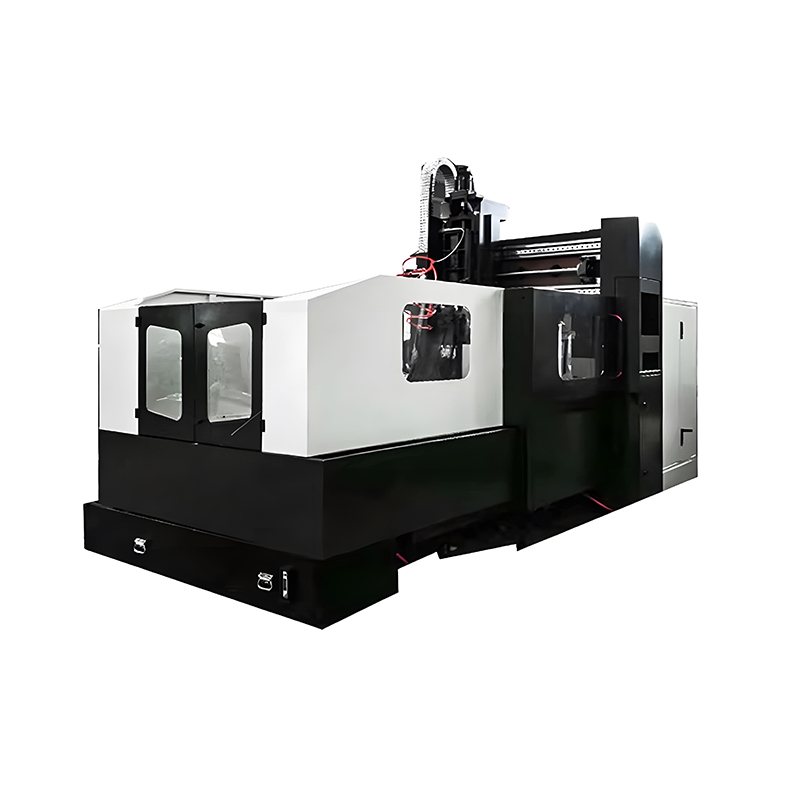

In the world of manufacturing, CNC machines are like highly skilled "super craftsmen," each with its own unique abilities. Although they are all computer-controlled, their functions are very distinct. Understanding the five most c...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español