READ MORE

We provide quality products and services to customers from all over the world.

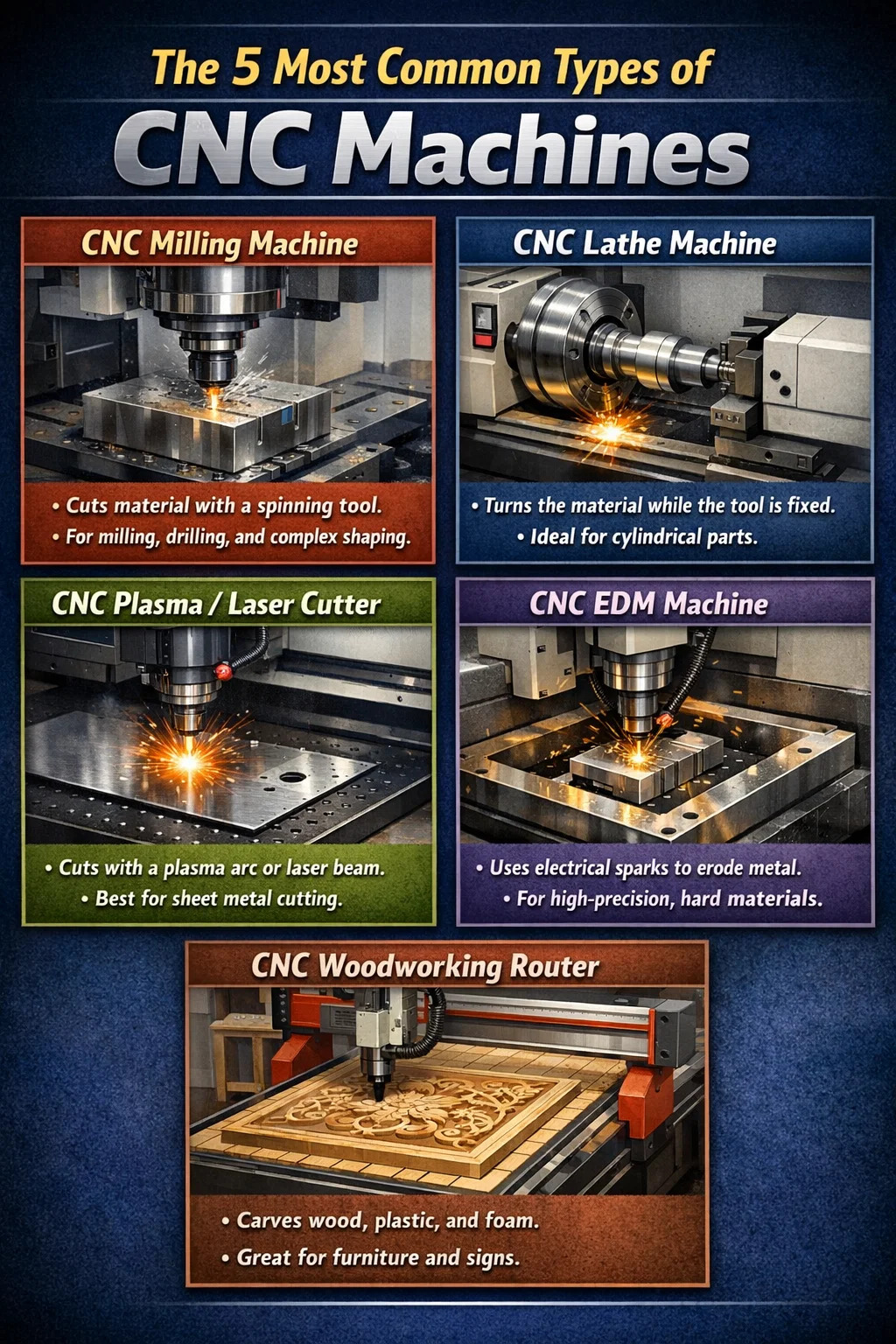

What are the 5 common types of CNC machines?

In the world of manufacturing, CNC machines are like highly skilled "super craftsmen," each with its own unique abilities. Although they are all computer-controlled, their functions are very distinct. Understanding the five most common types will help you quickly determine which machine is best suited for your task.

Here's an introduction to the five most common types of CNC machines:

1. CNC Milling Machine

This is one of the most widely used types. You can imagine it as a hand holding a high-speed rotating cutting tool, "carving" on a fixed material.

How it works: The material is fixed on the workbench, and the tool, under computer control, cuts into the material from different directions, removing the excess.

Specialty: Drilling holes, milling grooves, and processing various complex planar or three-dimensional parts. Whether it's a metal block or a plastic block, it can transform it into the desired shape.

2. CNC Lathe Machine

The working principle of a lathe is the opposite of a milling machine. On a lathe, "the material moves, the tool doesn't."

How it works: It clamps the material on the spindle and rotates it at high speed, then uses a fixed cutting tool to approach it. Like a potter shaping a pot on a rotating wheel, it "shapes" the material into a round form.

Specialty: Specifically designed for processing cylindrical parts, such as shafts, bolts, connectors, or any circularly symmetrical objects.

3. CNC Plasma/Laser Cutter

These two types of machines are usually grouped together because they both perform "flat cutting."

How it works: They don't use physical cutting tools, but rather a beam of extremely high-energy laser or plasma arc. Like an invisible "lightsaber," wherever it goes, the metal sheet is instantly cut.

Specialty: Cutting complex contours and patterns on large sheets of steel or aluminum, at extremely high speeds, and with usually very clean cuts.

4. CNC Electrical Discharge Machining (EDM) Machine

This is a rather unique type of CNC machine; it doesn't rely on hard cutting, but on "electrical sparks."

How it works: It uses the ultra-high temperature generated by electrical discharge to erode the metal. This method can process materials with extremely high hardness that ordinary tools simply cannot cut.

Its specialty: Machining deep grooves and small holes in precision molds, or working with exceptionally hard alloy steels. Its movements are very precise, allowing for extremely high-precision details.

5. CNC Woodworking Engraving Machine (CNC Router)

These machines look somewhat like milling machines, but they are usually larger and more lightweight.

How it works: It also uses high-speed rotating tools, but it mainly targets materials with lower hardness. Its worktable area is often very large, allowing for a whole sheet of material to be placed on it.

Its specialty: Processing wood, composite panels, plastics, foam, or soft metals (such as aluminum). It is the absolute workhorse for furniture making, signboard engraving, and wooden door processing.

NEXT:Which CNC machine is best for a beginner? A beginner's guide.

Interested in cooperation or have questions?

-

How a Vertical Machine Works: The Core Principle A vertical machine — specifically a vertical machining center (VMC) — works by holding a cutting tool in a vertically oriented spindle that moves downward into a stationary or repo...

READ MORE -

Direct Answer: What is the Price Range for a 3-Axis CNC? The cost of a 3-axis CNC machine varies drastically based on its build quality, intended application, and precision capabilities. You can expect to pay anywhere from $500 f...

READ MORE -

Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español