Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

What brands are vertical machining centers?

Top Tier Manufacturers of Vertical Machining Centers

When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovation. The most prominent brands globally include Haas Automation, Mazak, Okuma, DMG Mori, Fanuc, Doosan (now DN Solutions), and Makino. Each of these manufacturers offers a range of CNC machines tailored to different sectors, from small job shops requiring versatility to high-volume aerospace facilities demanding extreme accuracy.

Choosing the right brand depends on your specific machining requirements, such as spindle speed, torque, tool change time, and the level of service support available in your geographic region. Below is a detailed breakdown of these brands and what they bring to the machine shop floor.

North American and European Giants

Haas Automation: The American Workhorse

Haas is arguably the most recognizable brand for vertical machining centers in the United States. Their VF series, ranging from the small VF-1 to the massive VF-12, has become the industry standard for general-purpose machining. Haas machines are favored for their proprietary, user-friendly control system and a massive network of Haas Factory Outlets (HFOs) that provide rapid parts and service.

DMG Mori: German Engineering Meets Japanese Precision

A powerhouse in the CNC world, DMG Mori produces high-end vertical machining centers like the CMX V and NVX series. These machines are engineered for shops that cannot compromise on rigidity or thermal stability. They are frequently used in medical and high-precision tool-and-die work where every micron counts. Their CELOS control system integrates digital manufacturing workflows directly into the machine interface.

Japanese Innovation and Reliability

Mazak: Advancing Multitasking and Speed

Mazak is renowned for its MAZATROL conversational programming, which allows operators to program complex parts right at the machine without needing separate CAM software for every task. Their vertical machining centers, such as the VCN and VC-Primos series, are designed for high-speed material removal and reduced cycle times.

Okuma: Total Control and Thermal Management

Okuma is unique because they build the machine, the spindle, the drives, and the OSP control system in-house. This "single-source" philosophy ensures that every component of their vertical machining centers communicates perfectly. Their Thermo-Friendly Concept is a game-changer for shops in non-climate-controlled environments, as it allows the machine to compensate for temperature changes automatically.

Fanuc: The King of Production Drilling and Tapping

While Fanuc is famous for its CNC controls, they also produce the RoboDrill, a high-speed vertical machining center primarily used for drilling, tapping, and light milling. If you are machining small electronics components or aluminum parts in the thousands, the RoboDrill is often the fastest machine on the floor.

Comparative Analysis of Popular VMC Brands

Selecting a brand involves balancing the machine's capabilities with its price point. The table below provides a general comparison of the market positioning for these leading vertical machining centers.

| Brand | Market Strength | Control System | Best For... |

|---|---|---|---|

| Haas | Affordability & Service | Haas NextGen | General Job Shops |

| Mazak | Versatility & Logic | MAZATROL | Complex Prototyping |

| DMG Mori | High-End Rigidness | CELOS (Siemens/Fanuc) | Medical & Aerospace |

| DN Solutions | Reliability & Value | Fanuc/Siemens | Heavy-Duty Cutting |

| Okuma | Precision & Stability | OSP-P300 | Tight Tolerance Parts |

Emerging and Specialized Brands

DN Solutions (formerly Doosan)

DN Solutions has become a favorite for shops looking for a heavy-duty machine without the extreme price of German or Japanese premium brands. Their DNM series of vertical machining centers is well-regarded for having heavy-duty linear guideways and high-torque spindles that handle steel and titanium better than many entry-level machines.

Hurco: The Conversational Leader

If you do not have a dedicated CAM department, Hurco is a brand you must consider. Their WinMax control is widely considered the best in the world for conversational programming. It allows an operator to take a 2D blueprint and program a vertical machining center in minutes, making them ideal for "one-off" parts and repair shops.

Key Factors When Evaluating VMC Brands

Beyond the badge on the machine, you should evaluate these brands based on tangible performance metrics that will impact your bottom line:

- Spindle RPM and Interface: Do you need 10,000 RPM for aluminum or 30,000 RPM for micro-milling? Brands like Makino specialize in these ultra-high speeds.

- Tool Change Speed: In high-volume production, a 1.5-second tool-to-tool time (like on a Fanuc RoboDrill) can save hours over a week compared to a slower 5-second changer.

- Service Availability: No matter how good the vertical machining centers are, they will eventually need maintenance. Choose a brand that has a local technician and a parts warehouse nearby.

- Expansion Capability: Can the machine be fitted with a 4th or 5th-axis rotary table later? Haas and Mazak are particularly good at offering "field-installable" upgrades.

Conclusion on Brand Selection

The "best" brand for vertical machining centers is the one that aligns with your specific part complexity and budget. For those starting out or running a general job shop, Haas and DN Solutions offer the best balance of cost and capability. For those in high-precision industries like aerospace or medical, the investment in Mori Seiki (DMG Mori), Okuma, or Makino often pays for itself through reduced scrap rates and superior surface finishes.

Before making a purchase, always request a "test cut" from the dealer using your own material and part program. This ensures that the brand you choose can actually deliver the tolerances your customers demand.

Interested in cooperation or have questions?

-

-

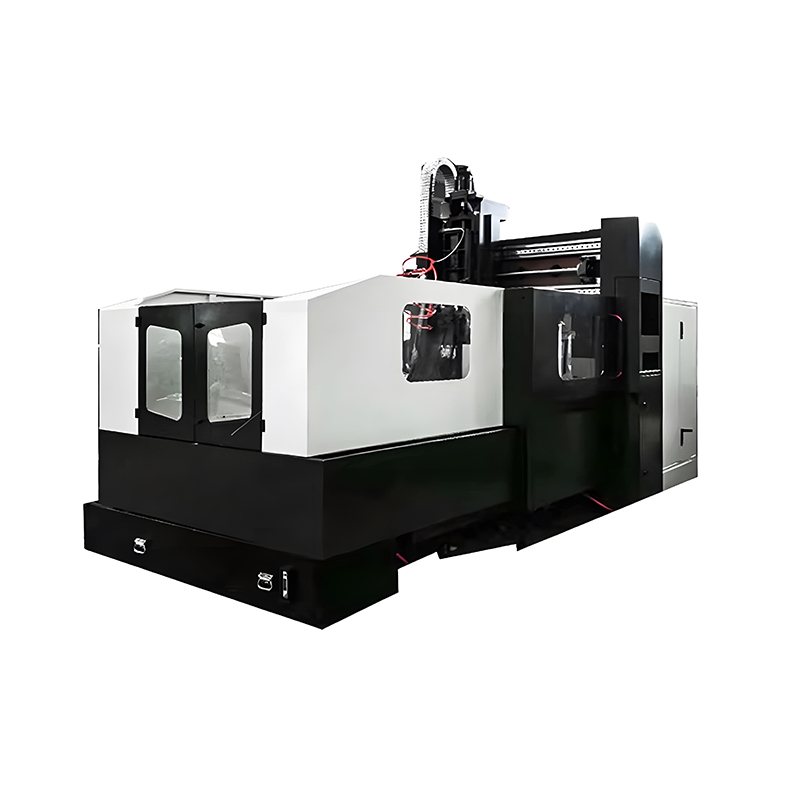

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

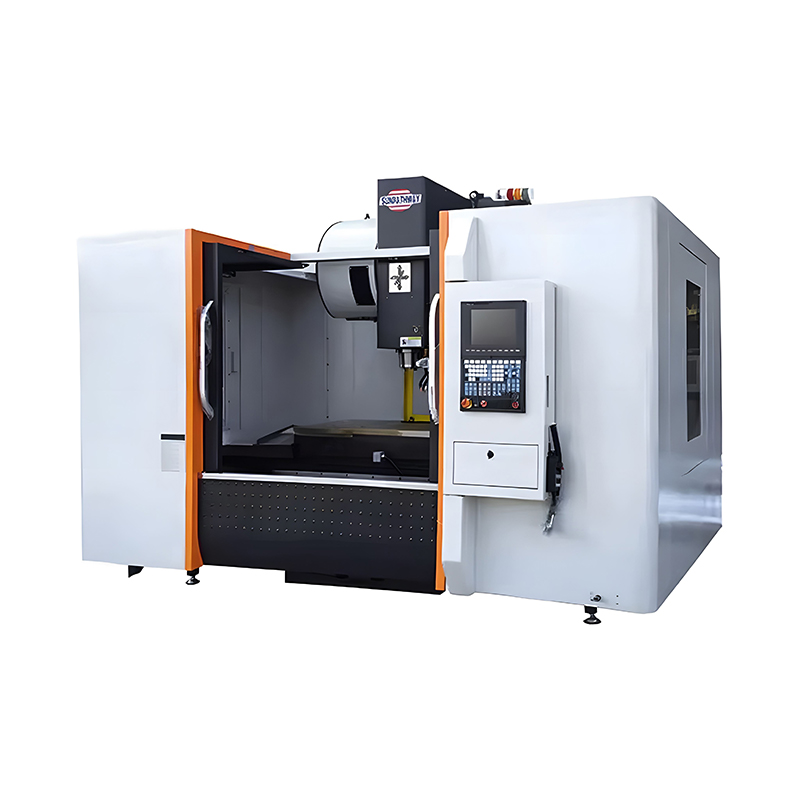

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español