Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MOREWe provide quality products and services to customers from all over the world.

What are vertical machining centers?

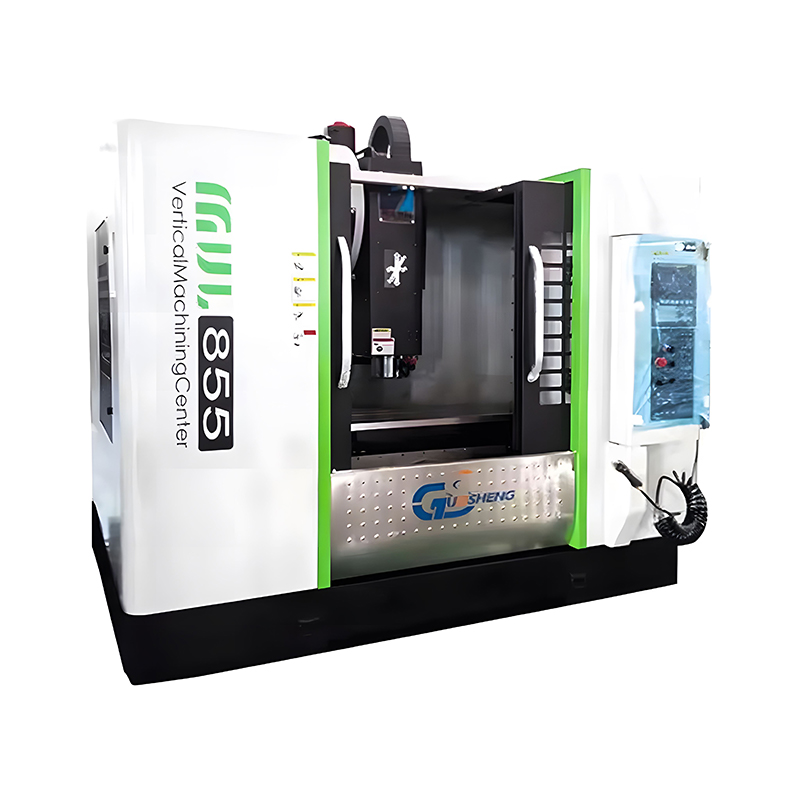

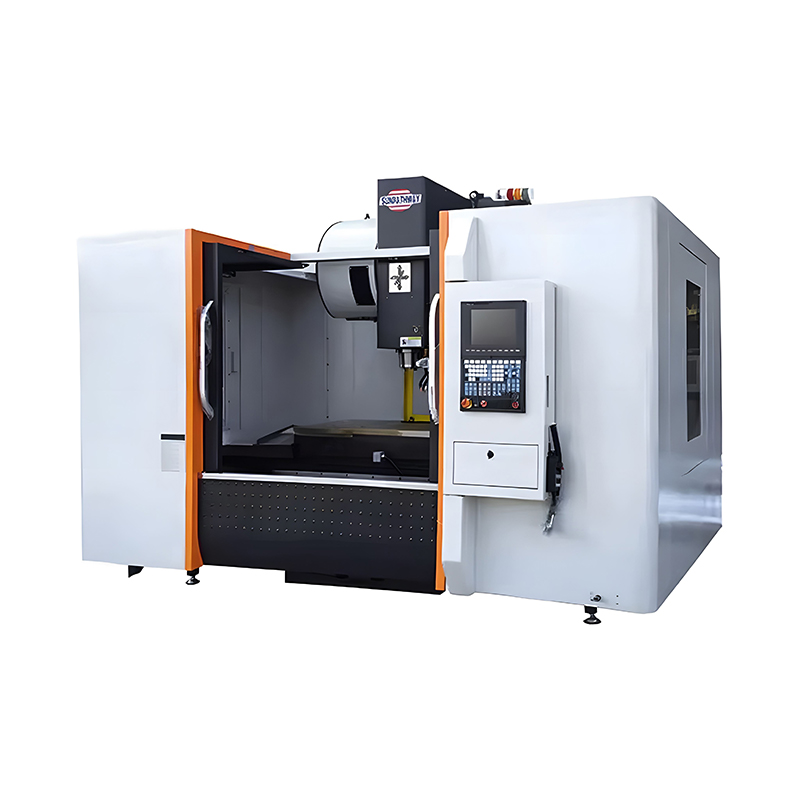

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type.

It's like an enhanced, fully automated "vertical milling machine." Here's a detailed explanation:

1. Why is it called "vertical"?

This name comes from the direction of its spindle (the part that holds and rotates the cutting tool).

Vertically downward: In vertical machining centers, the spindle points vertically downwards towards the ground. This means the cutting tool cuts the workpiece from top to bottom.

Gravity advantage: This layout is very intuitive; standing in front of the machine, you can easily see how the tool "carves" the material surface.

2. How is it different from a regular milling machine?

Although they look somewhat similar, vertical machining centers are much more sophisticated.

Automatic tool changer: This is its biggest feature. The machine usually has a disc-shaped or chain-shaped "tool magazine" containing dozens of different tools. During processing, the machine can automatically switch between drill bits, milling cutters, and taps according to the program, without any manual intervention.

Fully enclosed protection: These machines usually come with a large metal enclosure. This is to block flying metal chips and coolant, making the working environment cleaner and safer.

3. How does its worktable move?

The working logic of most vertical machining centers is:

Workpiece moves, tool moves: The material is usually fixed on the worktable and moves left and right (X-axis) and back and forth (Y-axis), while the rotating tool moves up and down (Z-axis) to control the cutting depth.

Flexible coordination: Through the precise coordination of these three directions, it can process planes, steps, holes, grooves, and even complex three-dimensional curved surfaces.

4. What kind of work is it best suited for?

Due to its structural characteristics, this machine is a workhorse in many industries:

Mold manufacturing: It is the most commonly used tool for processing various metal molds.

Parts processing: For example, automotive parts, mobile phone casings, and even metal parts for medical devices are mostly "milled" by this machine. Single-sided machining: If most of the machining work on your part is concentrated on one side, a vertical machining center is the most convenient option because clamping is very easy.

5. Why is it the preferred choice for many factories?

Small footprint: Compared to horizontal machining centers, the vertical structure is more compact, saving factory space for the owner.

Affordable price: Under the same precision requirements, vertical machining centers are usually cheaper than other types of machining centers, leading to a faster return on investment.

Easy to use: Because of better visibility and a clearer structure, beginners can learn to operate them much faster than horizontal machines.

6. Small details to pay attention to

Chip removal issues: Because of vertical cutting, the metal chips tend to accumulate on the workpiece surface or in the holes. Therefore, during operation, a strong stream of coolant is usually needed to flush away these chips and prevent them from scratching the machined surface.

Interested in cooperation or have questions?

-

-

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE -

For many manufacturers, a CNC machine is not just a tool, but an asset with amortization costs over many years. Its lifespan isn't a fixed date, but rather depends on how you "treat" it. Here are some key dimensions that determi...

READ MORE -

In the world of manufacturing, CNC machines are like highly skilled "super craftsmen," each with its own unique abilities. Although they are all computer-controlled, their functions are very distinct. Understanding the five most c...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español