Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technologic...

READ MORELM-1609 5 Axis CNC Gantry Milling Machine

Application scenarios and scope of application

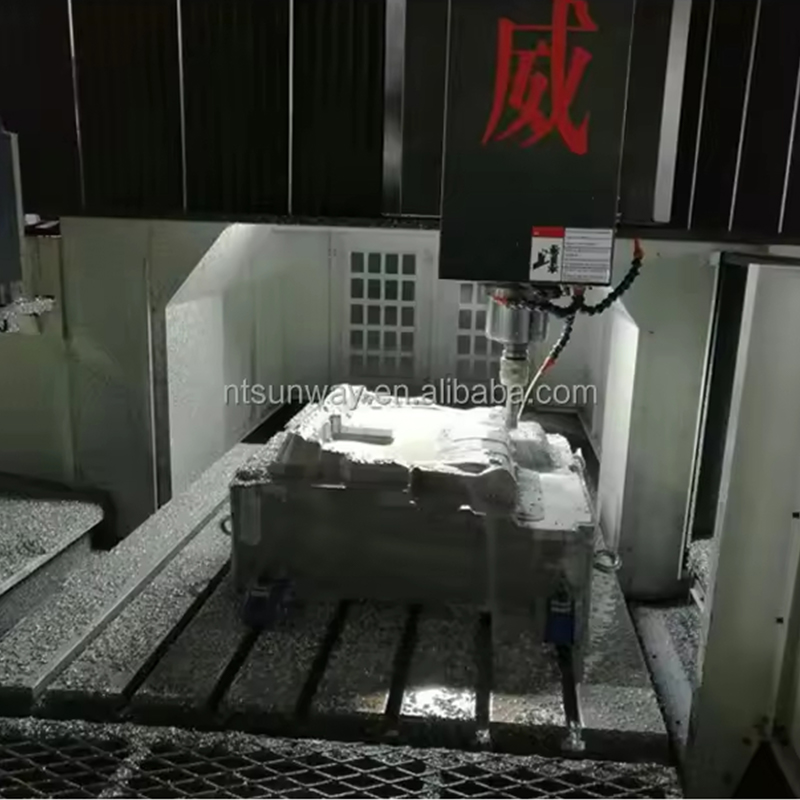

The LM-1609 is used in aerospace, automotive, and energy sectors for producing molds, turbine blades, and structural components. Its versatility extends to prototyping and small-batch production, meeting diverse industrial requirements.

Description

Contact us

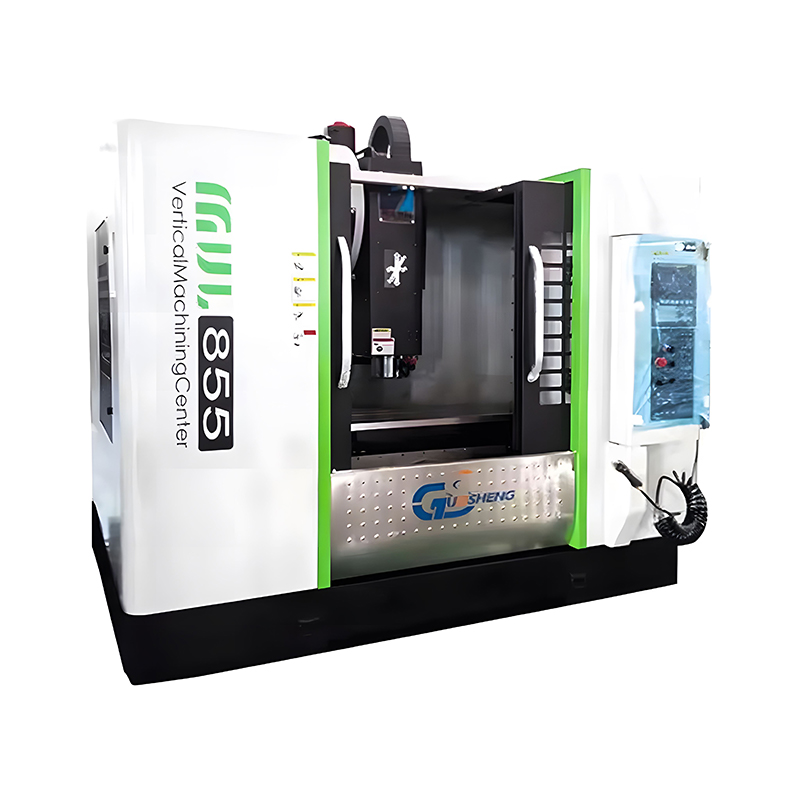

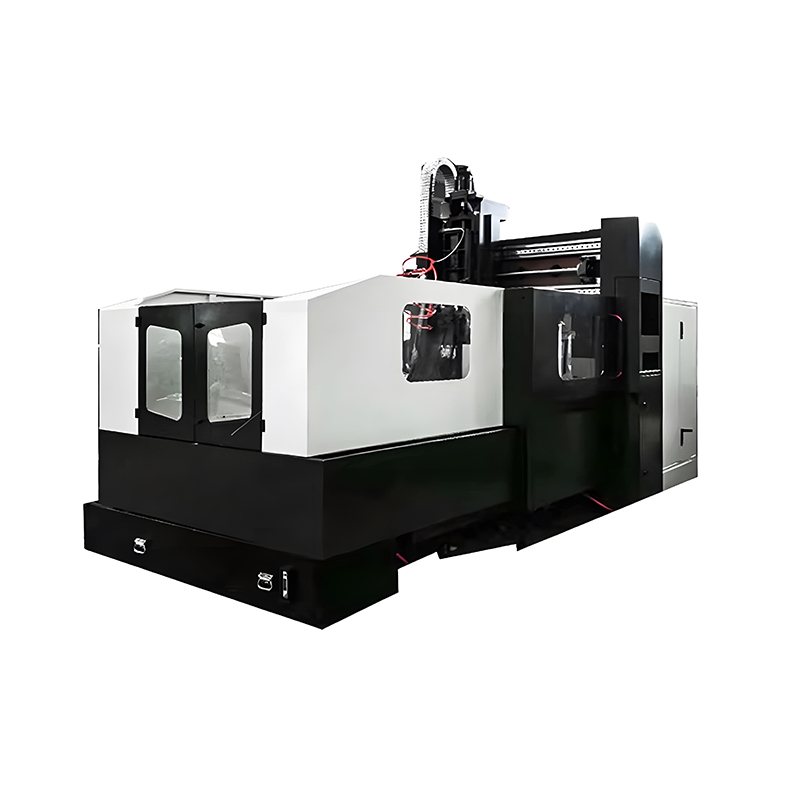

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring multi-surface processing. Its rigid gantry structure ensures stability during high-load operations, making it suitable for industries demanding intricate part fabrication.

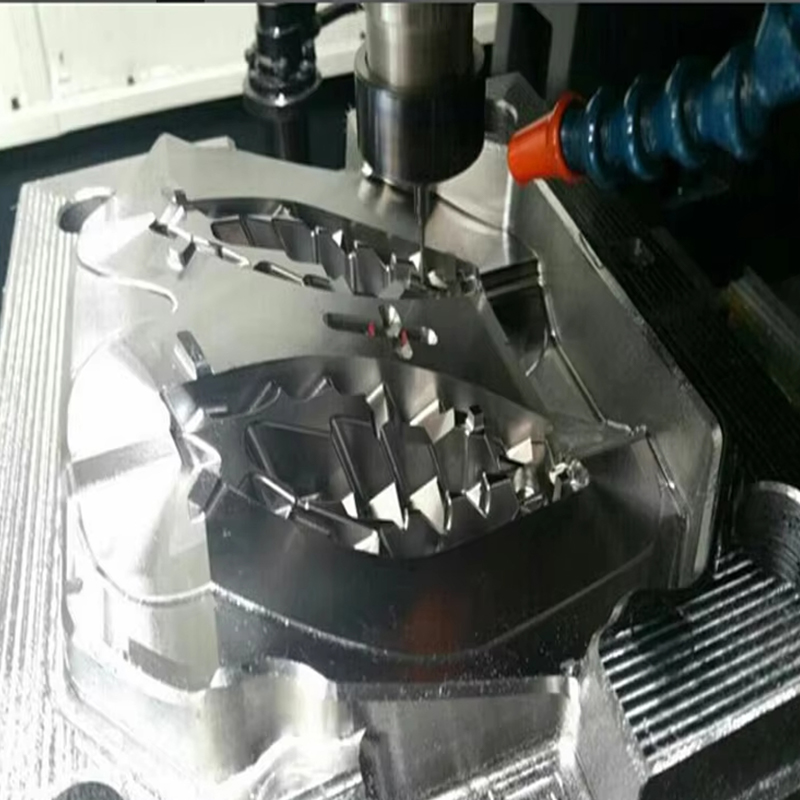

Equipped with a 5-axis linkage system, the LM-1609 enables simultaneous machining from multiple angles, reducing setup time and improving efficiency. The machine features a large worktable with a load capacity of up to 1600 kg, accommodating oversized workpieces. The integrated spindle offers a speed range of 50–12,000 rpm, supporting various materials, including metals and composites. A centralized lubrication system and thermal deformation compensation enhance operational reliability.

Product Features/Advantages

5-axis simultaneous control for complex geometries.

High-rigidity gantry construction minimizes vibration.

Precision ball screws and linear guides ensure consistent performance.

User-friendly CNC interface simplifies programming and operation.

The modular tooling system allows flexible configuration.

The LM-1609 combines advanced kinematics with robust engineering, delivering efficiency for demanding machining applications.

Specification

| model | LM-1090 (Light gantry milling) | LM-1311 (Light gantry milling) | LM1609 (Light gantry milling) | LM-1613 (Light gantry milling) | LM-1813 (Light gantry milling) |

| Workbench area (length × width) (mm) | 1000×750 | 1060×800 | 1300×1000 | 1600×800 | 1800×1200 |

| T-slot number (mm) | 5-14 | 5-18 | 5-18 | 7-18 | 7-22 |

| Spindle speed (r/min) | 3000~ 24000/21000 | 3000~24000/18000 | 3000~24000/18000 | 8000/15000 | 8000/15000 |

| Spindle output power (KW) | 3.2 | 3.2/4 | 4/5.5 | 4/5.5/7.5 | 15 |

| Spindle (Tool diameter range circumference) | φ3-φ12 | φ3-φ12 | φ3-φ12 | φ3-φ12/16 | φ150 BT40 servo |

| Three-axis travel (X*Y*Z axis) (mm) | Three-axis travel (X*Y*Z axis) (mm) | 450×400×200 | 500×500×250 | 600×600×250 | 1300×1800×700 |

| Minimum distance from spindle to table (mm) | 1300×1800×700 | Minimum distance from spindle to table (mm) | 30 | 60 | 150 |

| Gantry passage height (mm) | 150 | 150 | Gantry passage height (mm) | 230 | 850 |

We can provide you with a satisfactory plan!

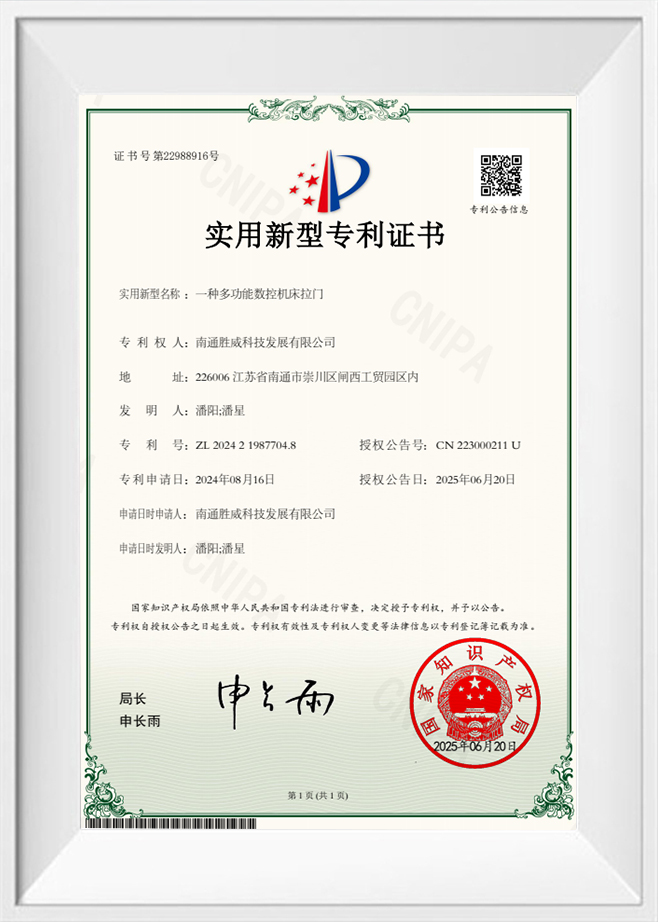

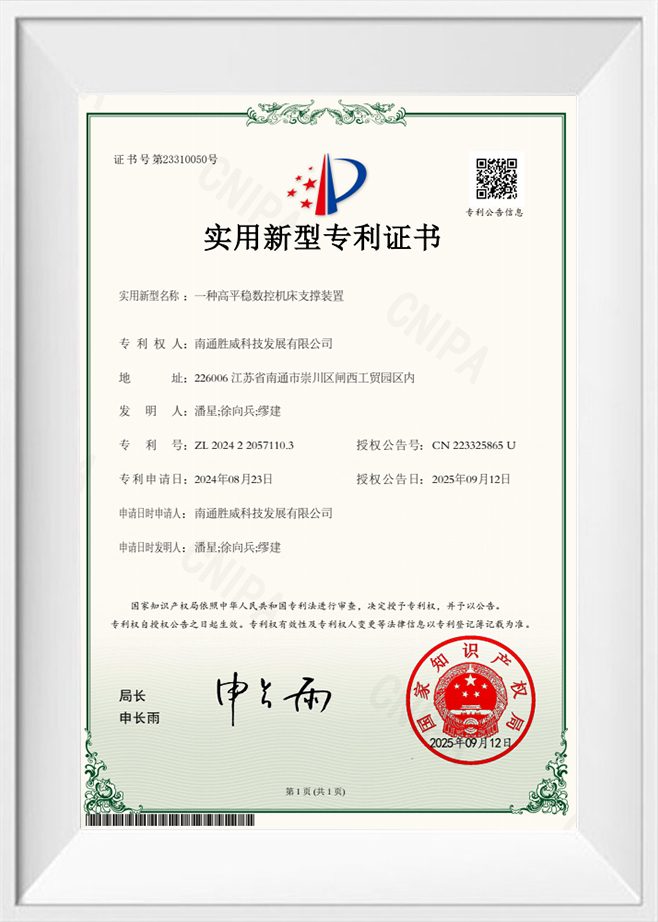

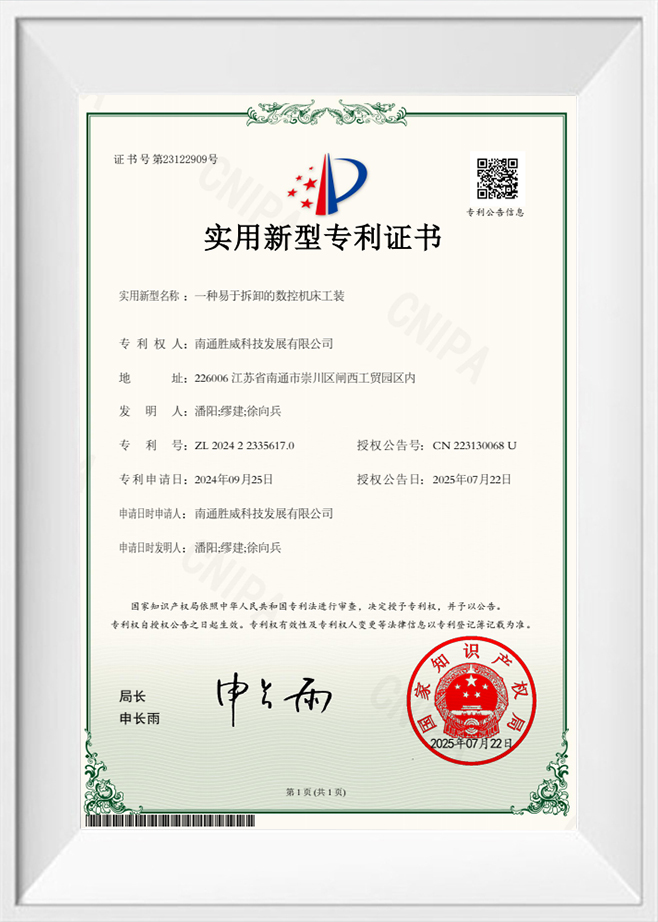

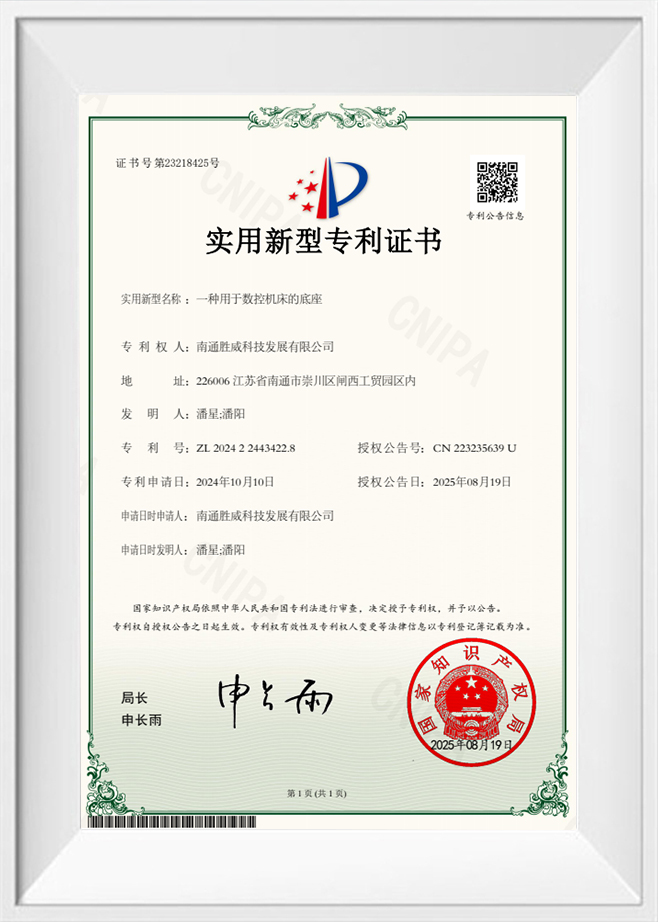

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approache...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vege...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an...

READ MORE

русский

русский Español

Español