Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

Which CNC machine is best for a beginner? A beginner's guide.

For beginners, the ideal CNC machine isn't necessarily the most powerful one, but rather the one that makes you "confident enough to get started" and has a "high tolerance for errors."

Here are a few types of machines suitable for beginners, along with the reasons why:

1. Desktop Engraving Machine (Beginner's First Choice)

If you have absolutely no experience and want to try it out at home on your desk or in your garage, this type of machine is the best starting point.

Assembly Fun: Many of these CNC machines are shipped as kits. Assembling it yourself allows you to understand how the guide rails, lead screws, and motors work together from the ground up.

Low-Cost Experimentation: Their unit price is usually low, so if you make a mistake, break a tool, or damage a part, the repair and replacement costs are low, reducing psychological pressure.

Suitable Materials: They are very suitable for processing wood, plastic, acrylic, and can even be used for soft metals (such as aluminum).

2. Gantry-Type Woodworking Engraving Machine (Intermediate Level)

If you've already decided to make furniture, signs, or large-scale crafts, choosing this type of machine will be more practical.

Large Working Area: Its bed is usually quite spacious, allowing you to place a whole piece of wood.

Simple and Clear Structure: Its movements are very intuitive; the movements in the X/Y/Z directions are easy to understand at a glance.

Extensive Community Support: This type of CNC machine has a very large user base, with a wealth of free tutorials and ready-made processing drawings available online. You can easily find answers to your questions with a quick search.

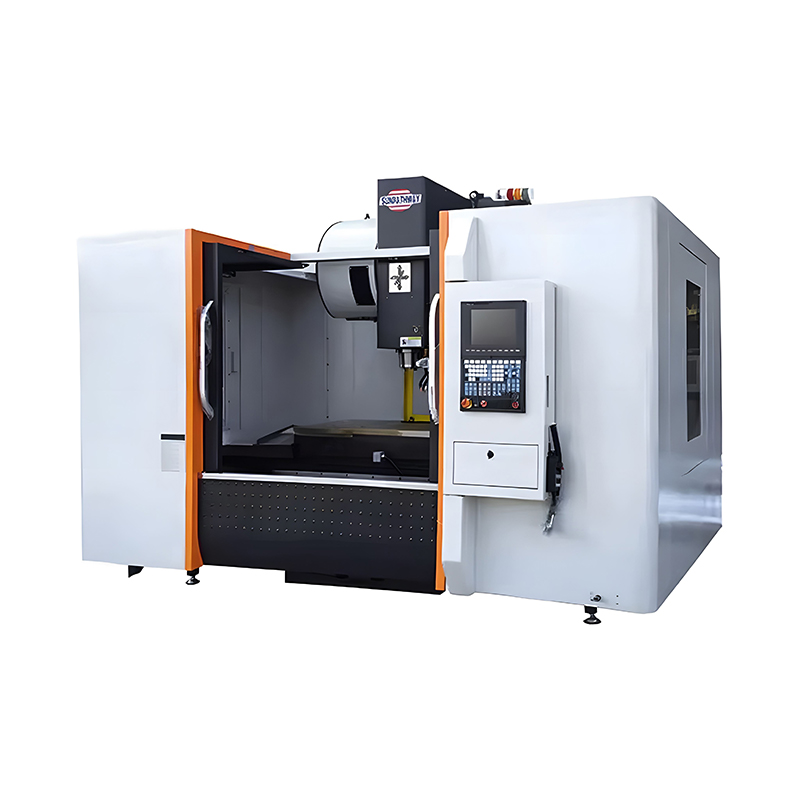

3. Integrated Enclosed Machine (For Convenience)

If you don't want chips flying everywhere during processing, and you don't want to deal with complex wiring, this type of machine is a typical "plug-and-play" option.

Safety Protection: The fully enclosed casing blocks flying chips and coolant, and also reduces noise during operation, making it ideal for indoor or educational environments.

Good Software Support: This type of machine usually comes with a very user-friendly control software, eliminating the need to delve into complex code; it's more like operating a printer.

4. Why is it not recommended for beginners to buy heavy-duty industrial machines directly?

Power and Space Requirements: Industrial-grade CNC machines typically require specialized industrial power supplies and reinforced foundations, which are difficult to accommodate in a typical residential setting.

Maintenance Costs: Every component of an industrial machine is expensive, and a single operational error can result in repair costs that exceed the price of a new entry-level machine.

Operational Complexity: Industrial systems have extremely complex buttons and commands, making independent operation difficult without professional training.

NEXT:Why you need a checklist for cnc machine operation (boost precision & safety)?

Interested in cooperation or have questions?

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

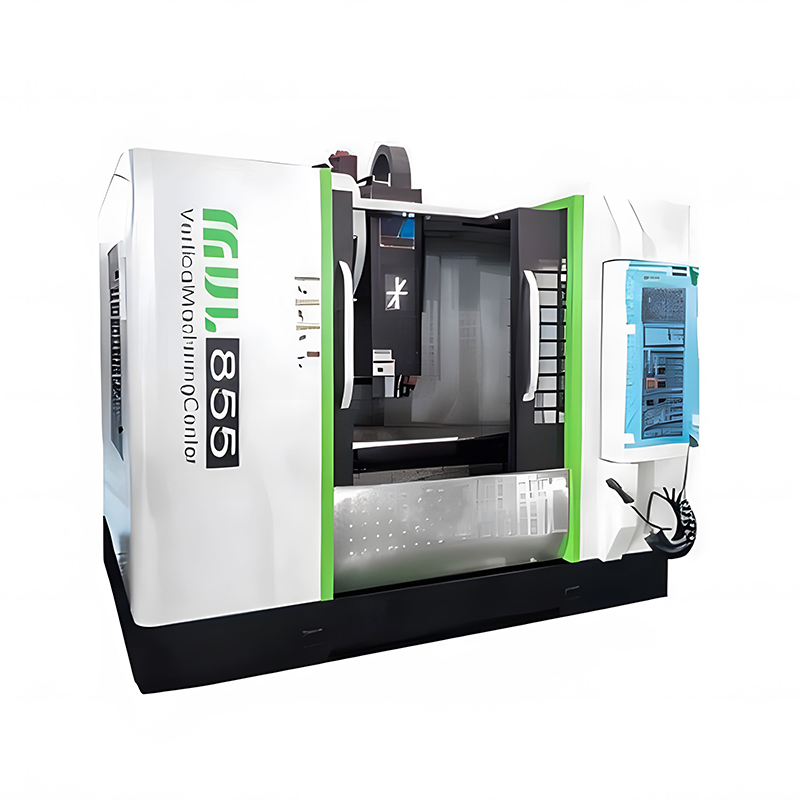

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español