Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

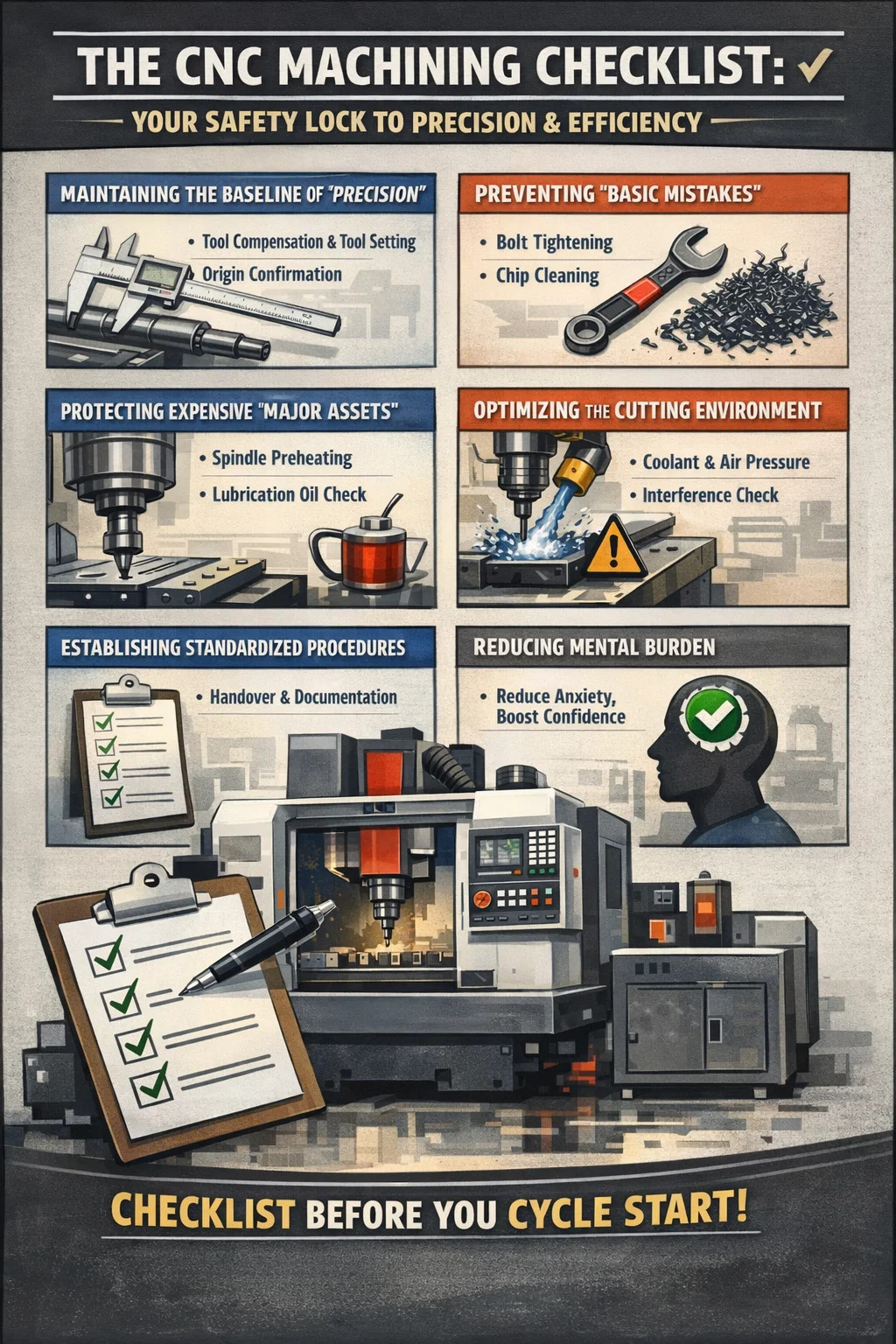

Why you need a checklist for cnc machine operation (boost precision & safety)?

Operating a CNC machine is like flying a plane or performing surgery; although the movements become smooth with practice, even the slightest oversight can lead to costly losses. A checklist isn't meant to restrict your freedom, but rather to add a "safety lock" to your machining process.

1. Maintaining the Baseline of "Precision"

A miss is as good as a mile. When machining precision parts, many subtle settings directly affect the quality of the finished product.

Tool Compensation and Tool Setting: The checklist will remind you to check if the tool length and diameter compensation are entered correctly. If the tool setting is inaccurate, the dimensions of the cut parts will be incorrect, potentially resulting in scrap.

Origin Confirmation: Confirming the coordinate origin is essential every time the machine is started or the workpiece is changed. The checklist helps you develop this habit, ensuring the CNC machine always starts working from the correct starting position, instead of cutting randomly into the air or the fixture.

2. Preventing "Basic Mistakes" Beyond the Expected

People are prone to distractions, especially after repeating the same operation many times; it's easiest to stumble in the simplest places.

Bolt Tightening: Have you really tightened the vise? Are the clamping plates loose? The checklist forces you to manually or visually confirm every fastener. If the workpiece loosens during high-speed operation of the CNC machine, the consequences will be irreversible.

Chip Cleaning: Even a small chip on the guide rails or clamping surface can slightly raise the workpiece. The checklist reminds you to clean before starting the machine, which is fundamental to ensuring flatness.

3. Protecting Expensive "Major Assets"

A CNC machine is expensive, and the spindle and ball screws are core components.

Spindle Preheating: Just like warming up a car engine, the checklist will remind you to run at a low speed for a few minutes to allow the bearing oil film to distribute evenly. Directly running at the highest speed will shorten the spindle's lifespan.

Lubrication Oil Check: Often, we get so engrossed in our work that we forget to check the oil level. The checklist forces you to check the oil level to ensure that the guide rails and ball screws are not damaged by dry friction during machining.

4. Optimizing the Cutting Environment (Safety First)

Safe operation is not only for the machine but also for protecting the operator. Coolant and Air Pressure: The checklist will help you confirm that the coolant level is sufficient and that the nozzle is properly aligned with the tool tip. Without sufficient cooling, the tool will quickly burn out. Also, if the air pressure is unstable, the tool change operation may jam.

Interference Check: Before pressing the start button, the checklist will remind you to check if the tool path will collide with the fixture, clamping plate, or machine guard. This "mental simulation" can save you a lot of money on machine repairs.

5. Establishing Standardized Operating Procedures

If you're not working alone, or if you want to improve the consistency of your work, standardization is crucial.

Handover and Documentation: With a checklist, anyone taking over the CNC machine can check it according to the same standards. This reduces communication costs and ensures that the quality of each part remains consistent, preventing defective parts due to different operators.

6. Reducing Mental Burden

When facing complex machining programs, the psychological pressure can be significant.

Reducing Anxiety: Checking off items on the checklist one by one will give you more confidence when you press the "cycle start" button. You know that everything that needs to be checked has been checked, and the rest can be left to the CNC machine to perform reliably.

NEXT:Why 5-axis should be your first cnc machine?

Interested in cooperation or have questions?

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español