Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

Content

- 1 1. Reduces the hassle of repeated handling and clamping

- 2 2. Ability to machine extremely complex shapes

- 3 3. Improves the surface quality of parts (more aesthetically pleasing cutting effect)

- 4 4. Saves on tool costs and extends service life

- 5 5. A Leap in Learning Curve

- 6 6. Extremely High Space Utilization and Commercial Competitiveness

Why 5-axis should be your first cnc machine?

Although many people recommend starting with simpler equipment, choosing a 5-axis CNC machine from the outset is actually a smart "one-step" strategy. For those who want to develop a long-term career in manufacturing, the advantages of this high-specification equipment are unparalleled by traditional machine tools.

Here are a few simple reasons why you should consider a 5-axis machine as your first CNC machine:

1. Reduces the hassle of repeated handling and clamping

On a regular 3-axis CNC machine, if you want to machine multiple surfaces of an object, you have to manually stop the machine, remove the workpiece, flip it over, and then precisely re-fixture it. This process is not only time-consuming but also prone to positional errors.

5-axis advantage: This machine allows the workpiece to be automatically rotated to the required angle after being fixed once, through the cooperation of two rotating axes. This means you only need to clamp the workpiece once to complete the machining of almost all surfaces except the bottom.

2. Ability to machine extremely complex shapes

If you want to make parts with curves, hollows, or complex shapes like propellers or impellers, ordinary CNC machines are difficult to handle.

Spatial freedom: The tool of a 5-axis machine can approach the workpiece from almost any angle. This is like writing with a pen; a 3-axis machine can only write vertically, while a 5-axis machine can draw smooth lines at an angle, like a sketch artist, easily handling various strange geometric shapes.

3. Improves the surface quality of parts (more aesthetically pleasing cutting effect)

When machining sloped surfaces, a 3-axis machine usually "scrapes" the surface little by little with the tip of the tool, resulting in a noticeable stepped appearance.

Better cutting angle: A 5-axis CNC machine can adjust the tool angle in real time, allowing the tool to always contact the material in the most ideal position. The resulting surface is very smooth, and often doesn't require laborious post-processing, allowing for direct production of finished products.

4. Saves on tool costs and extends service life

When machining deep grooves on a 3-axis machine, due to the fixed angle, you have to use very long and thin tools, which are prone to wobbling or even breaking. Short Tools for Global Reach: Five-axis machine tools allow shorter, thicker, and more robust tools to access confined spaces by tilting the workpiece or spindle. Shorter tools are more stable and less prone to wear, saving you money on tool replacements and making the machining process safer.

5. A Leap in Learning Curve

Many people worry that five-axis machine tools are too difficult to learn, but in fact, many advanced CNC machines now have very intelligent auxiliary software.

Long-Term Planning: Although it requires a little more effort to study spatial thinking at the beginning, once you master the operation logic of five-axis machines, three-axis or four-axis machines will seem incredibly easy. Instead of learning the basics and then spending money on upgrading equipment, it's better to go straight to the top and establish a more advanced machining mindset.

6. Extremely High Space Utilization and Commercial Competitiveness

If you want to use this machine to take on orders and make money, a five-axis machine tool allows you to take on jobs that others can't handle.

Competitiveness: Many high-precision industries (such as model aircraft, exquisite handicrafts, or medical devices) require five-axis machining. Owning such a CNC machine means that your workshop has the ability to handle challenging orders from the start, making you more competitive than workshops with only basic equipment.

NEXT:What's good to know before buying a CNC machine? (Some buying tips)

Interested in cooperation or have questions?

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

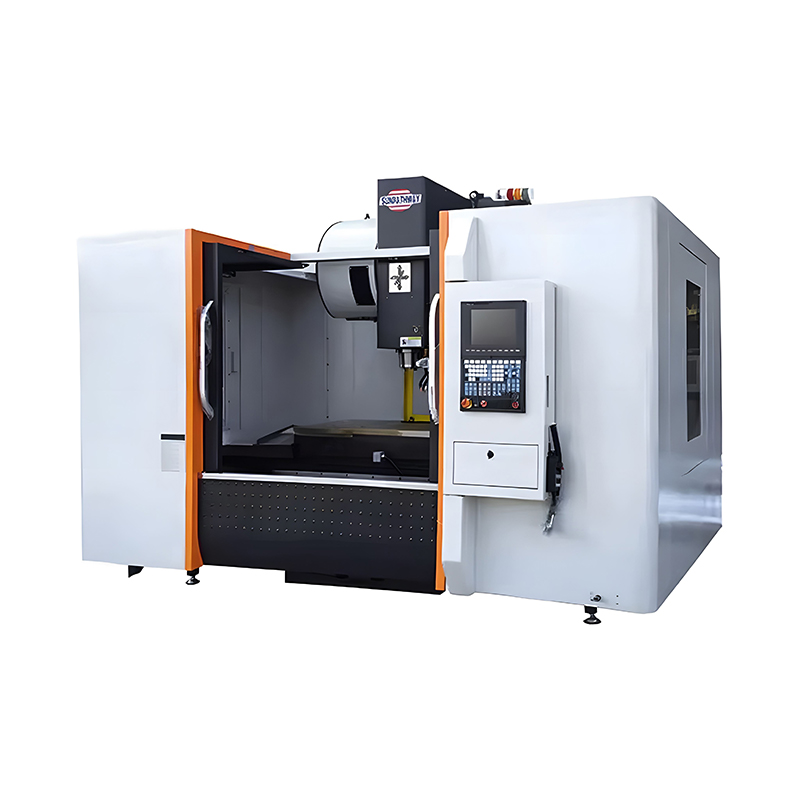

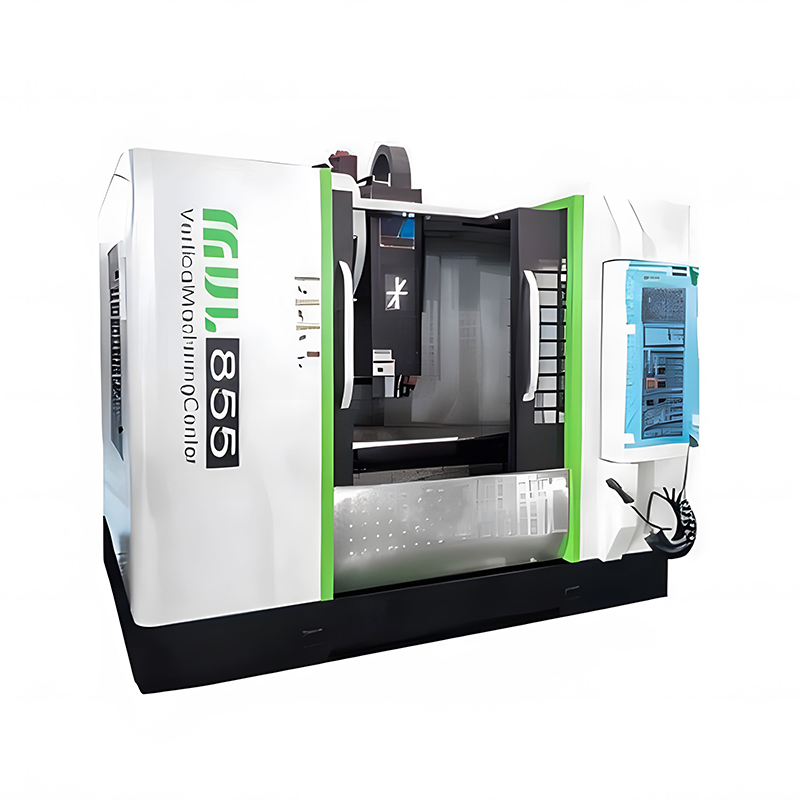

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español