Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

Content

- 1 1. What is Electrical Discharge Machining?

- 2 2. Main EDM Types

- 3 3. Core Working Principle

- 4 4. Typical Process Parameters (What Influences Cost & Quality)

- 5 5. Why Choose EDM?

- 6 6. Limitations & Risks

- 7 7. Typical Applications

- 8 8. How to Choose the Right EDM Machine

- 9 9. Dielectric Fluids – Types & Selection Criteria

- 10 10. Electrode Materials – Options & Trade‑offs

- 11 11. Maintenance & Best Practices

- 12 12. Typical Industrial Applications

- 13 13. Cost & ROI Considerations

- 14 14. Frequently Asked Buyer Questions

- 15 15. Emerging Trends

- 16 16. Quick Checklist for Buyers

- 17 17. Market Size & Growth Trends

- 18 18. Safety & Compliance

- 19 19. Common Pitfalls & Mitigation

- 20 20. Common Misconceptions (and the Truth)

- 21 21. Safety & Environmental Practices

- 22 22. Routine Maintenance Checklist

- 23 23. Machine Specifications to Compare

- 24 24. Relevant Standards & Certifications

Come And Learn About Electrical Discharge Machining (EDM)

1. What is Electrical Discharge Machining?

Electrical Discharge Machining is a non‑traditional, electrically‑driven machining process that removes material by a series of controlled spark discharges between a tool electrode and a conductive workpiece immersed in a dielectric fluid. The rapid, localized heating (10 000–50 000 °C) melts or vaporises the metal, and the debris is flushed away by the fluid. Because the process is contact‑free, it can machine extremely hard or brittle materials that are impossible to cut with conventional tools.

2. Main EDM Types

| Variant | Typical Use | Key Features |

| Die‑Sinking (or “EDM‑forming”) | 3‑D cavity and mould‑core production. | Electrode is a shaped solid (graphite, copper, tungsten) that is gradually eroded to match the cavity. |

| Wire EDM (WEDM) | Precision cutting of complex 2‑D profiles, thin‑wall parts, and micro‑features. | A continuously fed metal wire (copper, brass) acts as the electrode; the workpiece is moved relative to the wire. |

| Micro‑EDM | Sub‑micron holes, micro‑features for medical, aerospace, and MEMS. | Uses ultra‑short pulses, low energy, and specialised fluid to achieve <10 µm features. |

| Fast‑Hole EDM / High‑Speed EDM | Large‑volume drilling of hardened steels and super‑alloys. | Higher peak currents, optimized flushing, and advanced power electronics for faster material removal. |

| Hybrid EDM (e.g., EDM‑Milling, EDM‑Laser) | Combines EDM with other processes to improve surface finish or reduce machining time. | Recent research focuses on integrating ultrasonic vibration, laser assistance, or plasma‑assisted discharge. |

3. Core Working Principle

| Step | Description |

| Electrode & Workpiece | Both are connected to opposite poles of a pulse power supply and placed in a dielectric (usually de‑ionised oil, water‑based fluid or specialized oil). |

| Gap Control | A servo‑controlled system maintains a sub‑millimetre gap (typically 0.01–0.05 mm). When the gap reaches the breakdown voltage, the dielectric ionises and a spark forms. |

| Spark Discharge | The high‑energy spark creates a plasma channel; the intense heat melts/evaporates a tiny volume of the workpiece. |

| Debris Removal | The dielectric cools the molten metal, forming fine particles that are flushed out, exposing fresh material for the next spark. |

| Repeat | The cycle repeats thousands of times per second, gradually shaping the part to the desired geometry. |

4. Typical Process Parameters (What Influences Cost & Quality)

| Parameter | Effect on Machining |

| Peak Current | Higher current → faster removal but larger heat‑affected zone. |

| Pulse Duration | Longer pulses increase material removal; shorter pulses improve surface finish. |

| Voltage / Gap | Controls spark stability; too high a voltage can cause arcing. |

| Flushing Pressure & Dielectric Flow | Critical for debris removal; inadequate flushing leads to short‑circuiting. |

| Electrode Material | Graphite: low wear, good for roughing. Copper/Tungsten: low wear, high precision. |

| Polarity | Reverse polarity can reduce electrode wear for certain materials. |

| Machining Strategy (rough‑/mid‑/finish) | Multi‑stage programs optimise speed vs. accuracy. |

5. Why Choose EDM?

•Material versatility – works on any conductive material, regardless of hardness (titanium, hardened steel, tungsten carbide).

•Complex geometry – can produce intricate shapes, thin walls, and deep cavities that are impossible with conventional machining.

•No mechanical stress – the process is non‑contact, avoiding distortion or work‑hardening.

•High surface quality – smooth finishes (often < 0.2 µm) without secondary polishing.

6. Limitations & Risks

| Issue | Impact | Mitigation |

| Low material‑removal rate (MRR) – slower than conventional machining, especially for large volumes. | Higher production time & cost. | Use hybrid approaches (abrasive‑assisted EDM) or optimize spark parameters. |

| Electrode wear – electrode material erodes, affecting dimensional accuracy. | Need for frequent electrode replacement. | Choose durable electrode materials (graphite, copper‑tungsten) and monitor wear. |

| Dielectric handling – oil or de‑ionised water must be filtered and maintained. | Environmental & safety considerations. | Implement proper filtration and disposal systems. |

| High power consumption – requires robust power supplies. | Operating cost. | Evaluate energy‑efficient machines. |

7. Typical Applications

| Industry | Representative Parts |

| Aerospace & Defense | Turbine blades, fuel‑nozzle inserts, hardened moulds. |

| Automotive | Injection‑mould cavities, high‑strength gear blanks, electric‑vehicle battery housing. |

| Medical Devices | Stents, micro‑drill bits, surgical instrument cores. |

| Electronics | Micro‑holes for MEMS, PCB drilling, connector pins. |

| Tool & Die Making | Precision moulds, stamping dies, progressive die cavities. |

| Energy (Oil‑&‑Gas, Nuclear) | Drill‑bit tips, reactor component prototypes. |

| Research & Development | Micro‑structures, prototype parts for new alloys, surface‑texturing. |

8. How to Choose the Right EDM Machine

▸Define the Primary Application

•Wire EDM for 2‑D cutting of hard alloys.

•Die‑Sinking for mould cavities or 3‑D features.

•Micro‑EDM for sub‑10 µm holes.

▸Key Specification Checklist

•Power Rating / Peak Current (e.g., 5 kW for small machines, >30 kW for high‑speed drilling).

•Axis Travel & Accuracy (travel range, repeatability).

•Dielectric System (capacity, filtration, temperature control).

•Control Interface (PC‑based CNC, G‑code compatibility, offline programming).

•Tooling Options (automatic electrode changer, wire spool capacity).

▸Cost Considerations

•Capital Expenditure – Entry‑level machines start around USD 30 k; high‑end 5‑axis EDM can exceed USD 300 k.

•Operating Costs – Dielectric consumption, electrode material, electricity, maintenance contracts.

•Productivity ROI – Evaluate material removal rate vs. part value; high‑precision parts often justify higher machine cost.

▸Vendor Evaluation

•After‑Sales Service – Local technical support, spare‑parts inventory, training.

•Software & Integration – Compatibility with existing CAD/CAM workflow.

•Reference Projects – Ask for case studies in your target industry.

▸Future‑Proofing

•Look for machines that support high‑speed EDM, micro‑EDM, or hybrid modules (ultrasonic, laser‑assist) to stay competitive.

9. Dielectric Fluids – Types & Selection Criteria

| Fluid | Typical Application | Advantages | Drawbacks |

| Hydrocarbon oils (kerosene, mineral oil, EDM oil) | Die‑sink EDM | High dielectric strength, good cooling, stable spark control | Flammable, generates hazardous fumes, higher viscosity |

| De‑ionised water | Wire EDM, micro‑EDM | Low viscosity → fast flushing, higher MRR, no fire risk | Lower dielectric strength, can cause electro‑chemical corrosion on some alloys |

| Synthetic / biodegradable oils (e.g., castor‑oil‑based biodiesel) | Specialized high‑precision or eco‑friendly jobs | Reduced environmental impact, good thermal stability | May require additives to achieve required dielectric strength |

| Powder‑mixed dielectrics (graphite, Al, Si powders) | To boost MRR or surface finish | Improves spark stability, reduces dielectric strength, can lower wear | Requires careful filtration, possible contamination |

10. Electrode Materials – Options & Trade‑offs

| Material | Conductivity | Wear Resistance | Typical Use |

|---|---|---|---|

| Copper (pure, electrolytic) | Very high | Moderate | General purpose, high MRR |

| Graphite | Good | Low wear, high thermal resistance | Good surface finish, lower cost |

| Copper‑tungsten (≈70 % W / 30 % Cu) | Good | Excellent wear resistance, high melting point | Deep slots, carbide machining, high‑accuracy work |

| Silver‑tungsten, tungsten, brass, molybdenum | Varying | Specialized applications (e.g., high‑temperature, low wear) | |

| Composite / powder‑mixed electrodes | Tailored for specific MRR / wear balance |

11. Maintenance & Best Practices

| Activity | Frequency | Reason |

| Dielectric Filtration & Replacement | Every 500 h or as per fluid condition | Prevents contamination that can cause arcing. |

| Electrode Inspection | Before each job | Detect wear or damage that would affect accuracy. |

| Servo & Gap Calibration | Quarterly | Maintains spark stability and dimensional repeatability. |

| Coolant & Pump Checks | Monthly | Ensures proper flushing and temperature control. |

| Software Updates | As released | Improves machining algorithms and adds new features. |

12. Typical Industrial Applications

•Aerospace & automotive – machining hard alloys, turbine blades, gear blanks

•Mould & die making – complex cavities, high‑precision inserts

•Medical devices – surgical instruments, implants requiring fine surface finish

•Micro‑electronics & MEMS – micro‑holes, micro‑features on conductive substrates

13. Cost & ROI Considerations

| Cost Element | Typical Range | Impact on Decision |

| Machine price | 6 k–150 k (small sinker to high‑end multi‑axis systems) | Larger machines justify themselves for high‑volume or high‑value parts. |

| Electrode material | Copper ≈ 30 kg−1,Cu‑W≈ 120 kg⁻¹, Graphite ≈ $15 kg⁻¹ | Electrode wear rate (TWR) directly affects consumable cost. |

| Dielectric fluid | Oil ≈ |

Fluid consumption is proportional to machining time; recycling systems can lower long‑term cost. |

| Maintenance / filtration | Annual filter replacement ≈ |

Essential for stable spark and part quality. |

| Productivity | Typical MRR 0.5–5 mm³/min (sink) or 1–10 mm³/min (wire) | Higher MRR reduces machining time, improving ROI. |

14. Frequently Asked Buyer Questions

| Question | Answer |

| Can EDM machine non‑conductive materials? | Only after applying a conductive coating; otherwise the process requires both workpiece and electrode to be conductive . |

| Which dielectric gives the fastest cutting? | De‑ionised water typically yields higher MRR in micro‑EDM and wire‑EDM, while oil provides better stability for large‑volume sinker EDM . |

| What electrode should I choose for machining tungsten carbide? | Copper‑tungsten (70 % W) offers the best balance of high MRR and low tool wear for carbide . |

| How to minimise electrode wear? | Use high‑conductivity, high‑melting‑point materials (Cu‑W, Ag‑W), lower pulse energy, and maintain clean dielectric with proper filtration . |

| Is EDM environmentally safe? | Oil‑based dielectrics generate hazardous fumes; water‑based or biodegradable oils reduce health and ecological impact but may need additives for performance . |

| What maintenance is required? | Regular dielectric filtration (1‑2 µm), fluid replacement schedule (oil ≈ 6 months, water ≈ 12 months), electrode wear monitoring, and CNC controller updates . |

15. Emerging Trends

•High‑Speed EDM – New pulse‑power units delivering > 200 A peak with sub‑µs pulses, dramatically increasing removal rates while preserving surface integrity.

•Micro‑EDM & Nano‑EDM – Integrated with MEMS fabrication lines for sub‑10 µm features, using ultra‑clean dielectric and precision wire feed.

•Hybrid Processes – Combining EDM with ultrasonic vibration or laser pre‑heating to lower required energy and improve surface finish.

•AI‑Driven Process Optimization – Real‑time monitoring of spark data to auto‑tune parameters, reducing scrap and cycle time.

•Sustainable Dielectrics – Biodegradable, low‑toxicity fluids that meet stricter environmental regulations.

16. Quick Checklist for Buyers

•Define part geometry & material → select sinker vs. wire vs. micro‑EDM.

•Set performance targets (MRR, surface roughness, tolerance).

•Choose electrode material based on workpiece hardness and cost.

•Select dielectric (oil for robustness, water for speed & safety).

•Verify machine specifications (axis travel, peak current, filtration system).

•Calculate total cost of ownership (machine, consumables, maintenance, expected production volume).

•Confirm vendor support (spare parts, training, software updates).

17. Market Size & Growth Trends

| Segment | 2024 Market Value | Forecast (2025‑2033) | CAGR |

|---|---|---|---|

| Global EDM (all types) | USD 2.10 B (overall market) | USD 3.5 B by 2028 | ≈ 5 % |

| Wire EDM | USD 1.25 B (2024) | USD 1.85 B by 2033 | 5.0 % |

| Hybrid/laser‑assisted EDM | Emerging niche; research papers show rapid adoption in aerospace & composites | Expected to grow > 6 % annually as laser‑EDM integration matures |

18. Safety & Compliance

| Aspect | Requirement / Best Practice |

| Electrical safety | Interlocks, grounding, and emergency stop; comply with IEC 60204‑1 |

| Fire safety | Use oil‑based dielectrics only in fire‑rated enclosures; install flame‑suppressant systems |

| Environmental | Collect and treat spent dielectric according to local hazardous‑waste regulations; biodegradable fluids simplify disposal |

| Standards | ISO 9001 (quality), ISO 14001 (environment), ISO 45001 (occupational health), and machine‑specific IEC 61373 (vibration) are commonly required for OEM customers. |

| Operator training | Certified EDM training (e.g., CNC‑EDM operator course) reduces accidents and improves productivity |

19. Common Pitfalls & Mitigation

| Issue | Cause | Mitigation |

| Excessive electrode wear | High peak current, poor dielectric filtration | Reduce current, increase filtration frequency |

| Recast layer cracks | Over‑heating, slow flushing | Optimize pulse‑off time, improve dielectric flow |

| Wire breakage (wire EDM) | Improper tension, contaminated dielectric | Regular tension checks, dielectric cleaning |

| Surface roughness spikes | Unstable spark gap | Auto‑gap control, periodic gap calibration |

20. Common Misconceptions (and the Truth)

| Misconception | Reality |

| “Higher voltage always gives faster material removal.” | Excessive voltage can cause unstable arcs, increase surface roughness, and raise the risk of dielectric breakdown. Optimal voltage depends on gap distance and dielectric type. |

| “Copper electrodes are always the best choice.” | Copper offers high conductivity but wears faster on very hard alloys; copper‑tungsten or coated electrodes give better life on titanium, Inconel, and carbide. |

| “Wire EDM can drill through‑holes directly.” | Wire EDM creates a slot; a starter hole (laser‑drilled or conventional) is required for through‑holes. |

| “Oil‑based dielectrics are obsolete.” | Oil provides higher dielectric strength and better cooling for high‑current sink‑type EDM; water is preferred for micro‑EDM but not for high‑energy bulk removal. |

| “EDM is only for metal parts.” | Conductive ceramics and some carbon‑based composites can be machined if a conductive coating is applied, expanding EDM’s material palette. |

21. Safety & Environmental Practices

•High‑voltage protection – lock‑out/tag‑out procedures, insulated enclosures, and emergency‑stop circuits are mandatory to prevent lethal shocks.

•Dielectric fluid handling – oil‑based fluids require fire‑safety measures and regular filtration; water‑based fluids are gaining popularity for lower environmental impact.

•Ventilation & fume extraction – sparks generate metal vapour and ozone; local exhaust hoods with HEPA filters are standard in modern shops.

•Personal protective equipment (PPE) – dielectric‑resistant gloves, safety glasses, and hearing protection are required for operators.

22. Routine Maintenance Checklist

| Task | Frequency | Key Points |

| Dielectric fluid replacement / filtration | Every 500 h or per OEM recommendation | Keep contaminant level < 0.5 % to avoid arcing. |

| Electrode wear inspection | Daily (before run) | Measure electrode diameter; replace when wear > 10 %. |

| Wire tension & guide‑roll check (wire EDM) | Every shift | Ensure consistent tension to prevent wire breakage. |

| Spark gap calibration | Weekly | Verify gap using built‑in sensor; adjust for material. |

| Cooling system flush | Monthly | Clean pump and heat‑exchanger to avoid overheating. |

| Software/firmware update | Quarterly | Improves pulse control and adds safety diagnostics. |

23. Machine Specifications to Compare

•Travel axes (X‑Y‑Z) – determines maximum workpiece size.

•Spindle speed (wire EDM) – up to 250 m/min for high‑speed cutting.

•Power rating – 5 kW to 30 kW; higher power yields faster MRR.

•Control system – CNC vs. CNC + PLC; look for built‑in adaptive pulse control.

24. Relevant Standards & Certifications

•ISO 9001 – Quality management (mandatory for most OEMs).

•ISO 14001 – Environmental management (important for dielectric disposal).

•IEC 60204‑1 – Safety of electrical equipment.

•UL 61010‑1 – Safety for measurement, control, and laboratory equipment (U.S. market).

Interested in cooperation or have questions?

-

-

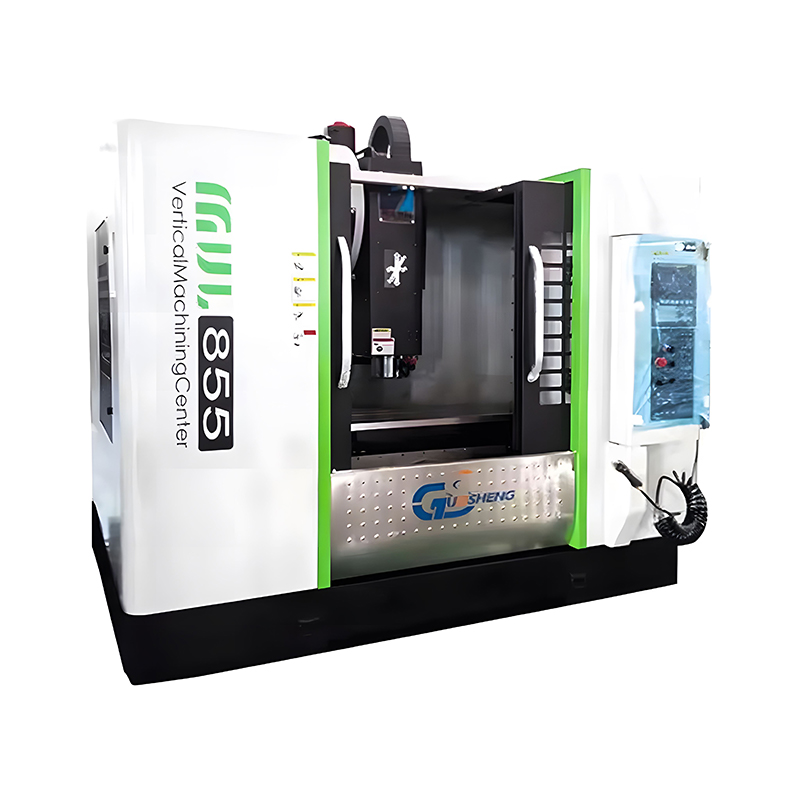

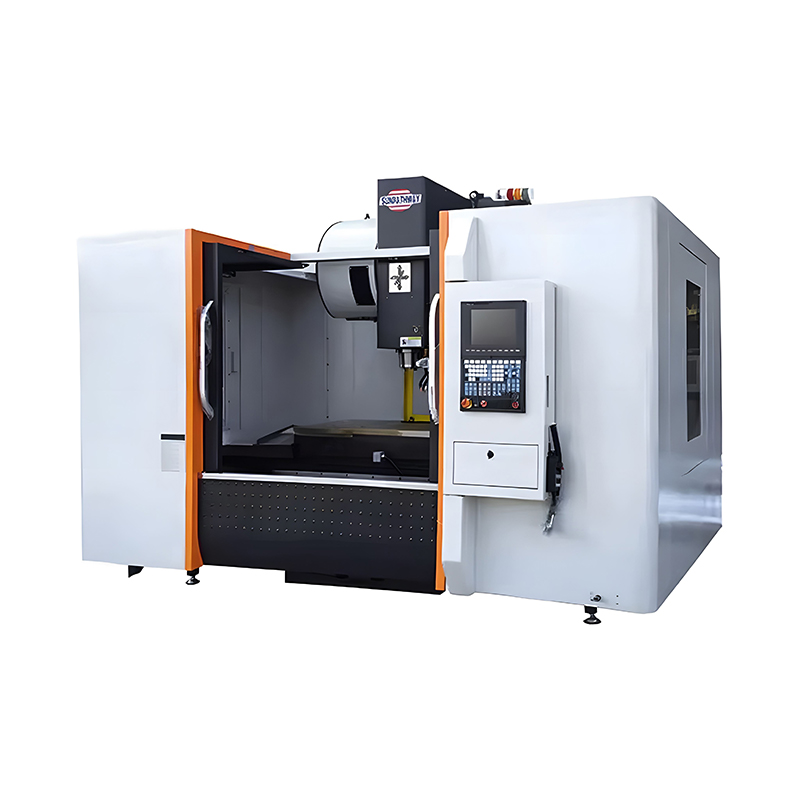

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español