Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

Content

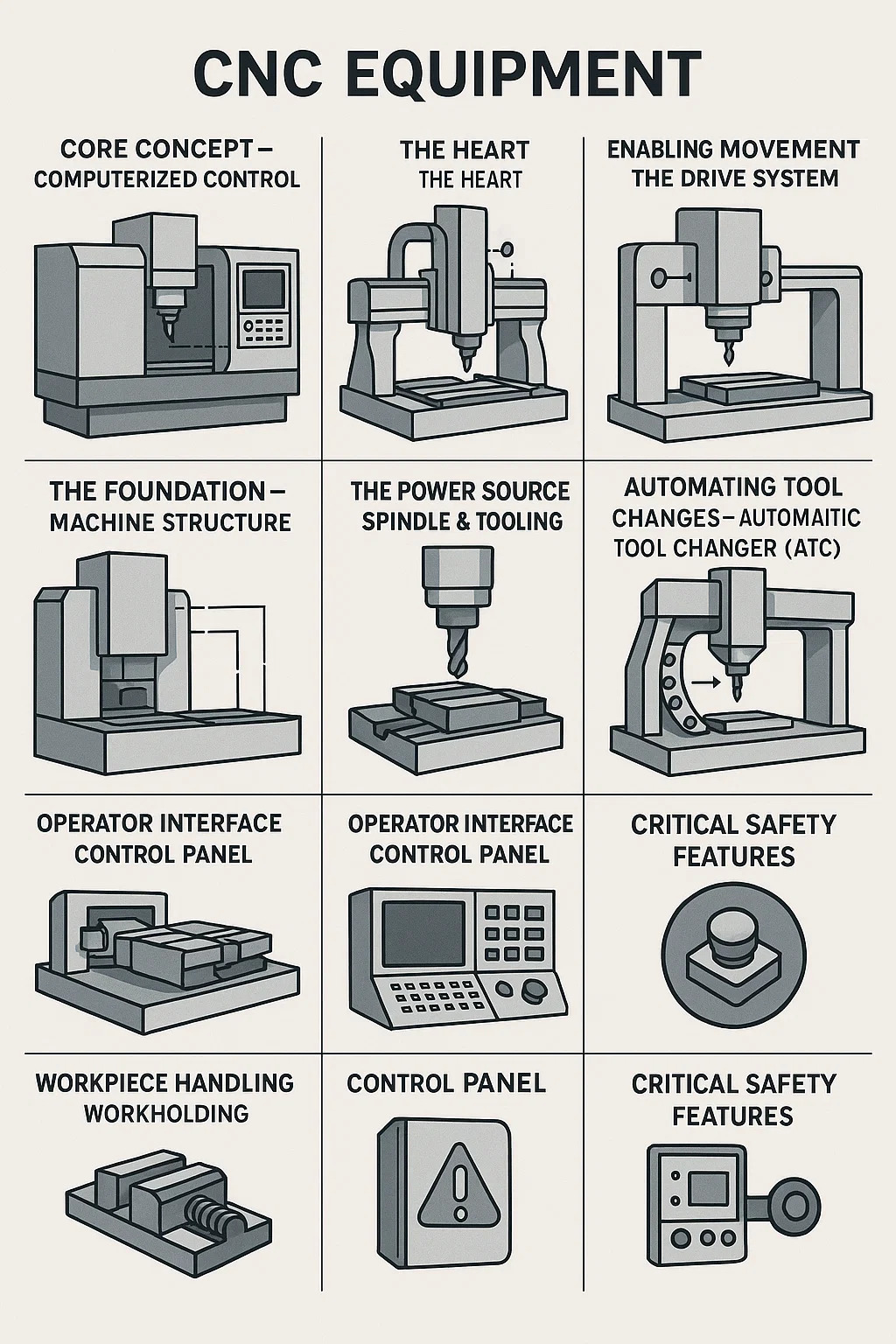

- 1 ■Core Concept - Computerized Control:

- 2 ■The Heart - The CNC Controller:

- 3 ■Enabling Movement - The Drive System:

- 4 ■The Physical Machine Tool:

- 5 ■The Foundation - Machine Structure:

- 6 ■The Power Source - Spindle & Tooling:

- 7 ■Automating Tool Changes - Automatic Tool Changer (ATC):

- 8 ■Workpiece Handling - Workholding:

- 9 ■Operator Interface - Control Panel:

- 10 ■Critical Safety Features:

- 11 ■Key Capabilities & Advantages:

What is CNC equipment?

Here's a clear breakdown of what CNC equipment is:

■Core Concept - Computerized Control:

•CNC stands for Computer Numerical Control.

•It refers to machinery where the operation and movement of tools are directed by pre-programmed computer instructions.

•These instructions (a CNC program) precisely dictate the machine's actions, replacing manual control by a human operator.

■The Heart - The CNC Controller:

•This is the specialized computer "brain" of the equipment.

•It interprets the programmed instructions (G-code and M-code are common languages).

•It sends precise electrical signals to the machine's motors and components to execute the programmed tasks.

■Enabling Movement - The Drive System:

•Comprises motors (servo motors or stepper motors) that convert the controller's electrical signals into physical movement.

•Includes mechanical components like ball screws, linear guides, or gearboxes that translate the motor's rotation into precise linear or rotational motion of the machine's axes (like X, Y, Z).

■The Physical Machine Tool:

•This is the actual mechanical structure that performs the manufacturing work.

•It holds the workpiece securely (using chucks, vises, fixtures).

•It holds and drives the cutting tool (like drills, end mills, turning tools) or other process tools (like lasers, plasma torches, routers).

•Common types include CNC Mills (machining centers), CNC Lathes (turning centers), CNC Routers, CNC Plasma Cutters, CNC Laser Cutters, CNC Grinders, etc.

■The Foundation - Machine Structure:

•Provides the rigid, stable platform necessary for precision machining.

•Typically made from heavy materials like cast iron or steel to absorb vibrations and maintain accuracy under cutting forces.

•Includes the machine bed, column, spindle housing, etc.

■The Power Source - Spindle & Tooling:

•The spindle is a high-precision rotating shaft that holds and drives the cutting tool at specific, often variable, speeds.

•Tooling refers to the various cutting tools (end mills, drills, inserts) mounted in the spindle or tool changer. Tool Holders secure these tools precisely in the spindle.

■Automating Tool Changes - Automatic Tool Changer (ATC):

•Found on many CNC machining centers (mills).

•A mechanism that automatically swaps different cutting tools in and out of the spindle during a program cycle.

•Allows a single machine to perform multiple operations (drilling, milling, boring) without manual intervention.

■Workpiece Handling - Workholding:

•Devices used to securely clamp and locate the raw material or workpiece onto the machine table or into the lathe chuck.

•Examples: Machine vises, chucks, clamps, specialized fixtures, pallet changers.

■Operator Interface - Control Panel:

•The physical console where the human operator interacts with the CNC machine.

•Includes a display screen, keyboard, manual controls (jog buttons, feed/speed overrides), and emergency stop buttons.

■Critical Safety Features:

•Includes emergency stop buttons, safety interlocks on doors, guarding, and sometimes light curtains or pressure mats to protect operators from moving parts and hazards.

■Key Capabilities & Advantages:

•High Precision & Repeatability: Can produce complex parts with extremely tight tolerances, consistently over many repetitions.

•Complex Geometries: Capable of machining intricate shapes and contours that are difficult or impossible to make manually.

•Automation: Once programmed and set up, the machine can run with minimal supervision for extended periods (lights-out machining possible).

•Increased Productivity: Faster machining speeds and reduced manual intervention lead to higher output rates.

•Flexibility: Changing the program allows the same machine to produce different parts, making it suitable for both mass production and small batch/job shop work.

Interested in cooperation or have questions?

-

-

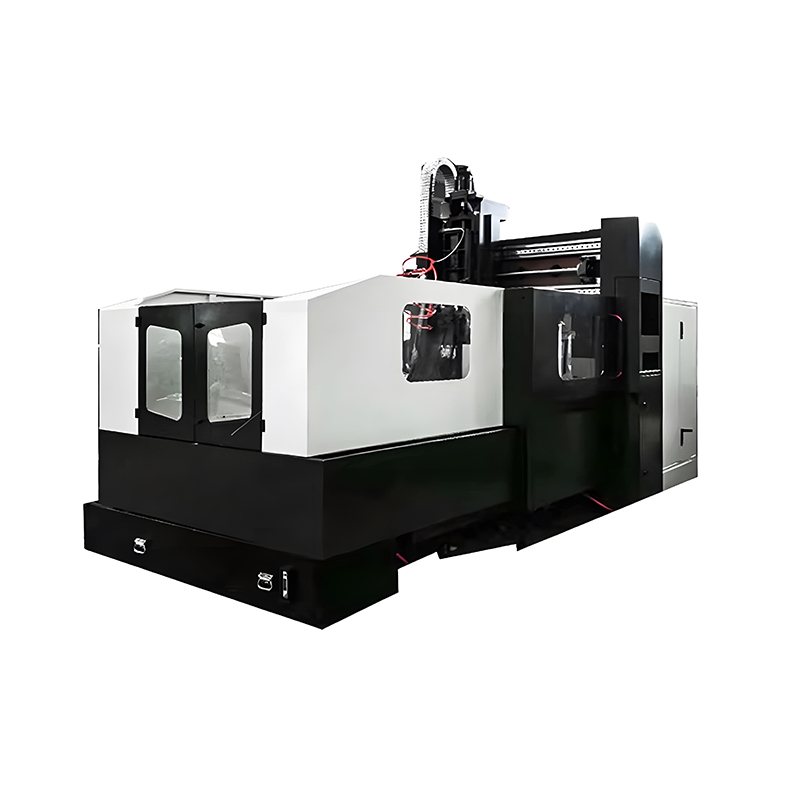

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

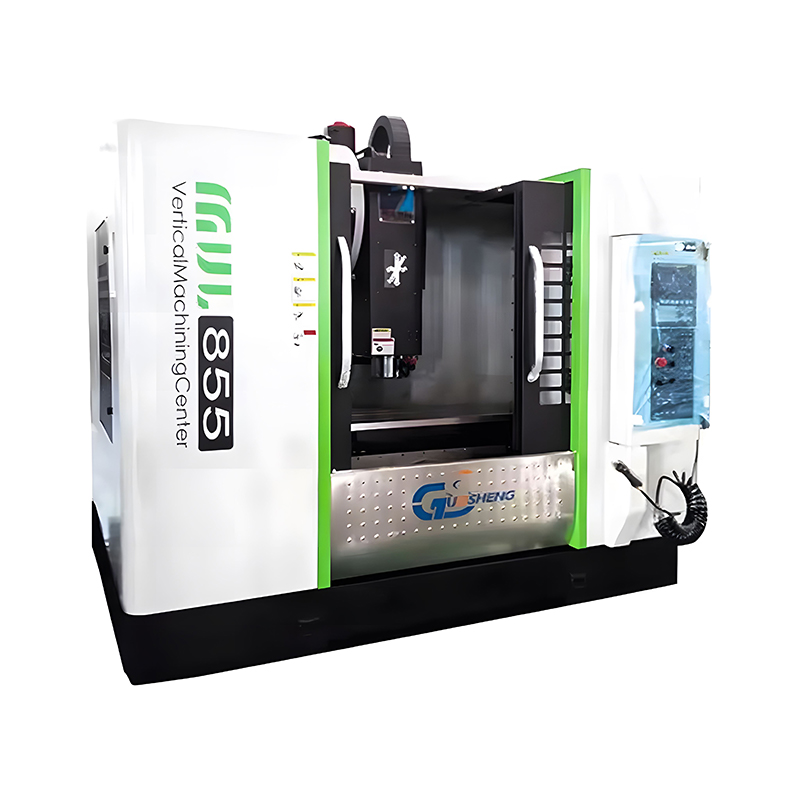

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español