Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

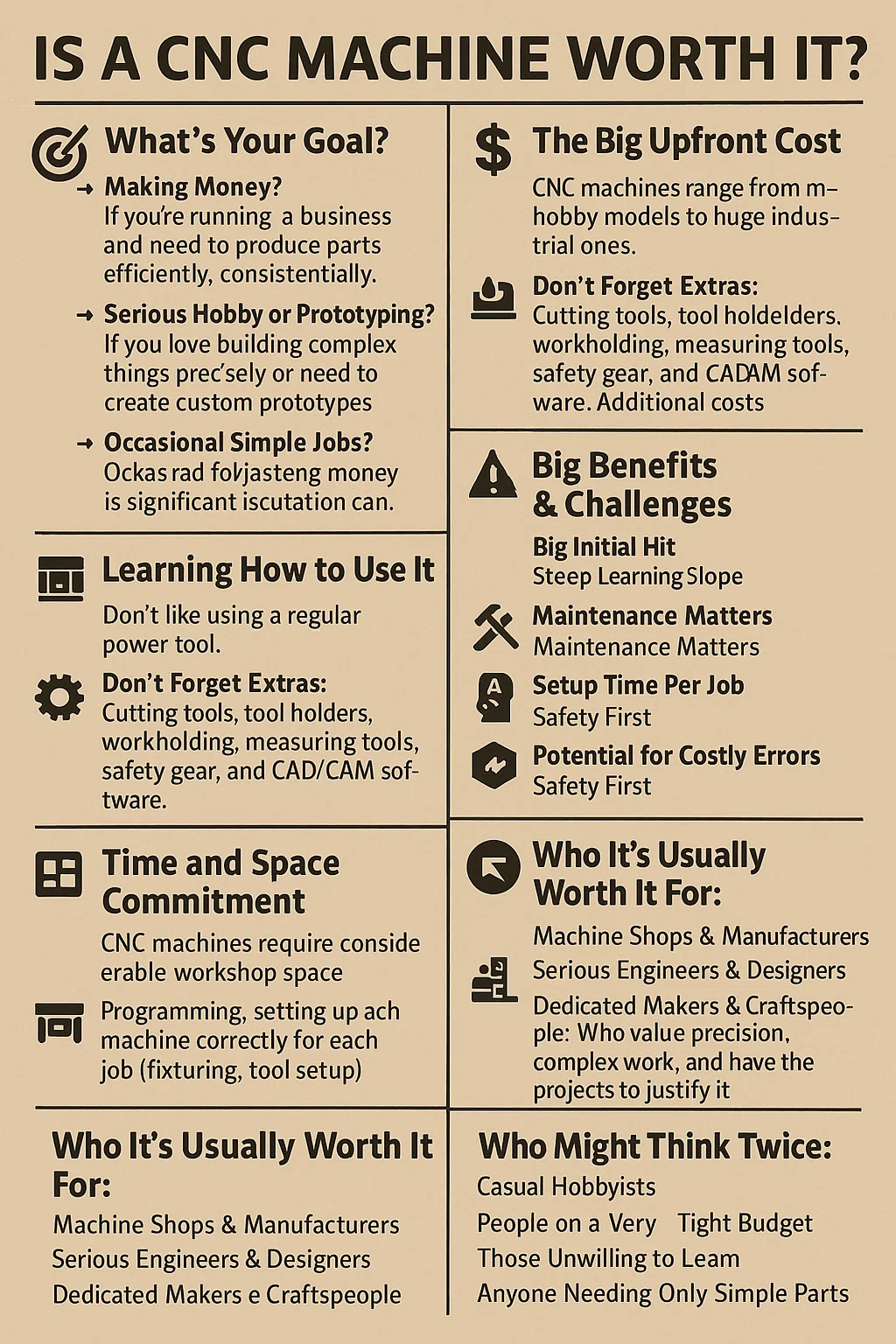

Is a cnc machine worth it?

Here's whether a CNC machine is worth it:

■What's Your Goal?

•Making Money? If you're running a business and need to produce parts efficiently, consistently, and potentially in quantity, a CNC machine is often essential and very worthwhile for staying competitive.

•Serious Hobby or Prototyping? If you love building complex things precisely or need to create custom prototypes often, the capability and satisfaction can make it worth the investment, even if it's a big expense.

•Occasional Simple Jobs? If you only need to make a few simple parts now and then, the high cost and learning curve might not pay off. Outsourcing or simpler tools could be smarter.

■The Big Upfront Cost:

•CNC machines themselves cost a lot, from smaller hobby models to huge industrial ones. This is the biggest hurdle.

•Don't Forget Extras: Budget for essential add-ons like cutting tools (bits, drills), tool holders, workholding (vises, clamps), measuring tools, safety gear, and necessary software (CAD for drawing, CAM for programming the machine). This adds up fast.

■Learning How to Use It:

•It's not like using a regular power tool. You need to learn both how to physically operate the machine safely and how to create the programs (using CAD/CAM software) that tell it what to do. This takes significant time and effort.

■Time and Space Commitment:

•CNC machines take up considerable workshop space. Smaller ones still need a solid, clean area.

•Programming, setting up the machine correctly for each job (fixturing, tool setup), and running the parts takes time. It's not instant.

■Big Benefits - Why People Do It:

•Super Precision & Repeatability: Makes identical parts, again and again, to very tight tolerances. Manual methods struggle to match this consistently.

•Complex Shapes Made Possible: Can create intricate curves, 3D surfaces, and detailed features that are extremely difficult or impossible to make manually.

•Hands-Off Production (Eventually): Once the program is proven and the machine is running, it can work unattended for hours, freeing you up for other tasks (great for production batches).

•Wide Material Range: Can handle metals, plastics, wood, composites effectively (depends on the specific machine type).

•Potential for Profit/Savings: For businesses, increased speed and reduced labor per part can lower costs and boost profits. For hobbyists, it can save money on custom parts you'd otherwise buy or outsource.

■The Downsides & Challenges:

•Big Initial Hit: The purchase price and setup costs are substantial.

Steep Learning Slope: Mastering programming and operation isn't quick or easy.

•Maintenance Matters: Like any complex machine, it needs regular care, cleaning, and occasional repairs, which cost time and money.

•Setup Time Per Job: Programming and physically setting up the machine (loading tools, securing material) takes effort before any chips fly. This makes very small runs (1-2 parts) sometimes less efficient than manual sometimes less efficient than manual work.

•Potential for Costly Errors: Mistakes in programming or setup can lead to broken tools, ruined material, or even damage to the machine itself. Attention to detail is critical.

•Safety First: CNC machines are powerful and can be dangerous. Proper training, guarding, and vigilance are non-negotiable.

■Who It's Usually Worth It For:

•Machine Shops & Manufacturers: Almost always essential for modern production.

•Serious Engineers & Designers: For prototyping and custom part creation.

•Dedicated Makers & Craftspeople: Who value precision, complex work, and have the projects to justify it.

•Businesses Needing Custom Parts: If outsourcing is expensive or slow, bringing it in-house can pay off.

■Who Might Think Twice:

•Casual Hobbyists: With simple or infrequent needs.

•People on a Very Tight Budget: The investment is significant.

•Those Unwilling to Learn: The programming and operation require commitment.

•Anyone Needing Only Simple Parts: Where hand tools or manual machines suffice.

Interested in cooperation or have questions?

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español