Top Tier Manufacturers of Vertical Machining Centers When searching for the industry leaders in vertical machining centers, several names consistently dominate the market based on reliability, precision, and technological innovat...

READ MOREWe provide quality products and services to customers from all over the world.

How much does a good cnc machine cost?

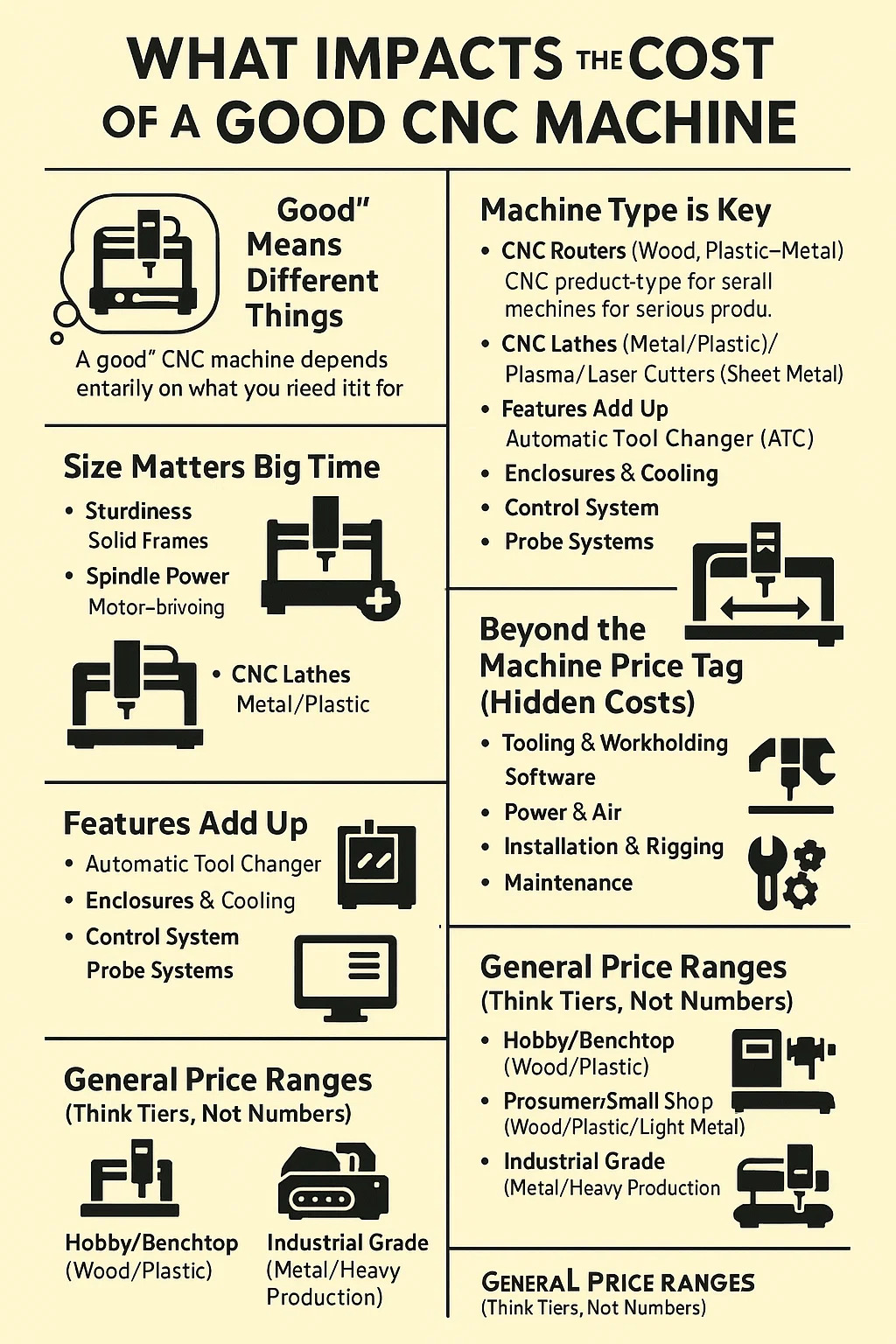

Here's a breakdown of what impacts the cost of a good CNC machine:

●"Good" Means Different Things:

•A "good" CNC machine depends entirely on what you need it for. A machine perfect for detailed woodworking in a home shop wouldn't be "good" for cutting thick steel plates in a factory, and vice versa.

●Machine Type is Key:

•CNC Routers (Wood, Plastic, Light Metal): Good quality hobby/small shop tabletop models cost less than industrial ones. Larger, sturdier machines for serious production work or tougher materials cost significantly more. Benchtop CNC routers are the most common entry point.

•CNC Mills (Machining Centers - Metal): These are generally more expensive than routers. Good quality small shop CNC mills (sometimes called "bench mills" or "toolroom mills") cost more than a router of similar size. Full-sized industrial CNC machining centers represent a major investment.

•CNC Lathes (Metal/Plastic): Similar to mills, small CNC lathes exist at a higher starting point than routers, with industrial turning centers being very costly. Good small CNC lathes are often sought after for precision parts.

•Plasma/Laser Cutters (Sheet Metal): Good CNC plasma tables for steel start higher than hobby routers. Industrial plasma or laser cutting CNC machines jump up substantially in price.

●Size Matters Big Time:

•The physical work area (how big a part it can handle) is a huge cost factor. A small benchtop CNC machine costs much less than a large-format model capable of handling sheet goods or big metal blocks. •Expect price to rise sharply as the cutting area increases.

●Build Quality & Power:

•Sturdiness: Machines built from heavy cast iron or welded steel frames cost more than lighter aluminum or bolt-together kits. A rigid CNC machine is essential for accuracy, especially cutting metal.

•Spindle Power: The motor driving the cutting tool. More horsepower (especially for metal CNC mills or tough materials) means a higher price tag. Spindle quality impacts precision and lifespan.

•Drive Systems: Precision ballscrews and strong motors (servo or stepper) cost more than basic leadscrews and weaker motors. This affects speed, accuracy, and ability to handle tough cuts.

●Features Add Up:

•Automatic Tool Changer (ATC): Lets the CNC machine swap tools by itself. This is a major convenience and productivity booster, adding significantly to the cost.

•Enclosures & Cooling: Full metal enclosures with coolant systems (essential for many metalworking CNC machines) increase cost but improve safety and part quality.

•Control System: Advanced touchscreen controls with more features cost more than basic interfaces. The "brain" of the CNC machine matters.

•Probe Systems: For automated tool setting or part measurement, adding cost but improving precision and setup speed.

●Beyond the Machine Price Tag (Hidden Costs):

•Tooling & Workholding: Cutting bits (end mills, drills), tool holders, vises, clamps, fixtures – essential accessories add hundreds to thousands to your total CNC machine investment.

•Software: You'll likely need CAD (drawing) software and CAM (toolpath programming) software. Good CAM software can be a major expense.

•Power & Air: Industrial CNC machines may need special electrical hookups (like 3-phase power) or compressed air lines.

•Installation & Rigging: Getting a large machine into your shop and set up might require professionals.

•Maintenance: Budget for regular upkeep and eventual repairs to keep your CNC machine running well.

●General Price Ranges (Think Tiers, Not Numbers):

•Hobby/Benchtop (Wood/Plastic): Least expensive tier, but still a significant purchase for an individual. Often smaller benchtop CNC routers.

•Prosumer/Small Shop (Wood/Plastic/Light Metal): A big step up in quality, size, and capability (and cost). Includes robust benchtop CNC mills/routers and small industrial units.

•Industrial Grade (Metal/Heavy Production): Represents a very serious business investment. Expect high costs for full-sized CNC machining centers, turning centers, or large industrial routers/plasma tables.

Interested in cooperation or have questions?

-

-

The Core Distinction Between Vertical and Horizontal Machining The fundamental difference between vertical and horizontal machining lies in the orientation of the spindle, which determines how the cutting tool approaches the work...

READ MORE -

Vertical machining is a machining method that uses the vertical movement of a cutting tool to cut materials. If you've ever seen an old-fashioned drill press, or imagine a chef vertically holding a knife and cutting vegetables on ...

READ MORE -

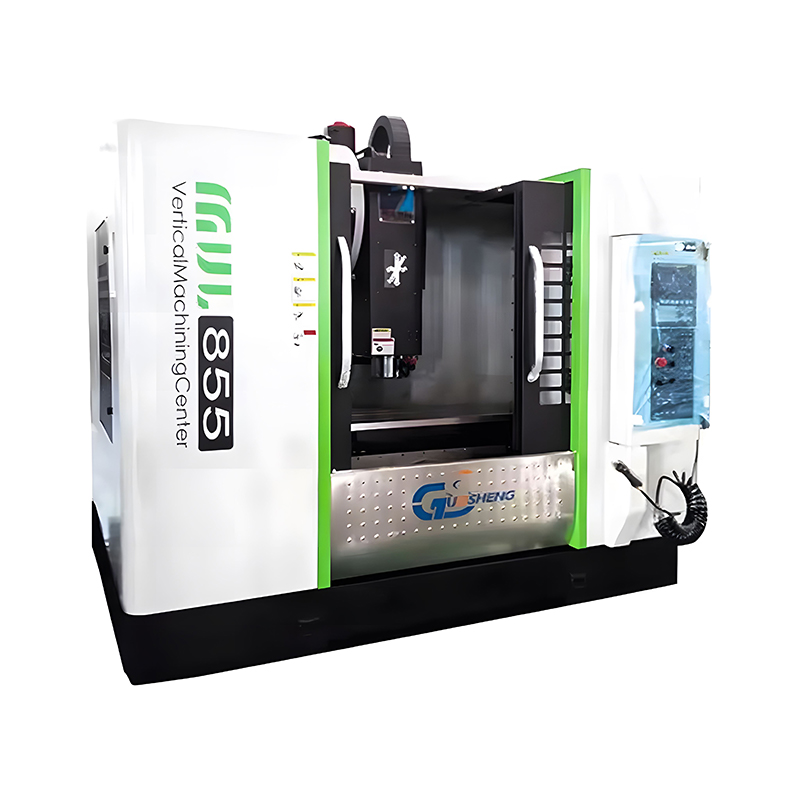

Among the diverse family of CNC machines, vertical machining centers (VMCs) are the most common and versatile. If you walk into a machine shop, you'll likely see more of these machines than any other type. It's like an enhanced,...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español