For beginners, the ideal CNC machine isn't necessarily the most powerful one, but rather the one that makes you "confident enough to get started" and has a "high tolerance for errors." Here are a few types of machines suitable for...

READ MOREWe provide quality products and services to customers from all over the world.

Content

- 1 1. What Is a CNC Gantry Milling Machine?

- 2 2. Core Components

- 3 3. Key Technical Parameters

- 4 4. Key Buying Criteria

- 5 5. Typical Applications

- 6 6. Advantages

- 7 7. Disadvantages / Trade‑offs

- 8 8. Buying Considerations

- 9 9. Common Buyer Questions & Quick Answers

- 10 10. Installation & Setup Checklist

- 11 11. Maintenance Best Practices

- 12 12. Typical Price Ranges (2025 market)

- 13 13. Evaluating Vendors

- 14 14. Frequently Overlooked Details

- 15 15. Quick Reference Cheat Sheet

- 16 16. Machine Types

- 17 17. Drive & Motion

- 18 18. Cooling & Chip Management

- 19 19. Safety & Compliance

- 20 20. Integration Options

- 21 21. Upgradability

- 22 22. Typical Lead Times

- 23 23. Financing & Leasing

- 24 24. After‑Sales Support

- 25 25. ROI Calculation Tips

- 26 26. Frequently Compared Alternatives

- 27 27. Choosing the Right Axis Configuration

- 28 28. Material Compatibility

- 29 29. Common Pitfalls & How to Avoid

- 30 30. Quick Decision Matrix

- 31 31. Environmental Considerations

- 32 32. Energy Consumption Tips

- 33 33. Remote Monitoring

- 34 34. Common Accessories

CNC Gantry Milling Machine Comprehensive Knowledge Guide

1. What Is a CNC Gantry Milling Machine?

A CNC (Computer‑Numerical‑Control) gantry milling machine is a large‑format machining center where the cutting head (spindle) moves along a bridge‑like structure (the gantry) that spans the workpiece. This design provides a wide travel area, high rigidity, and the ability to machine heavy or oversized parts in a single setup.

2. Core Components

| Component | What It Does | Why It Matters to Buyers |

| Gantry (Bridge) | Supports the spindle and moves it in X‑ and Y‑axes. | Determines the maximum width of the workpiece and overall stiffness. |

| Spindle | Holds the cutting tool and rotates at high speed. | Affects surface finish, tool life, and the types of materials you can cut. |

| Linear Guides & Ball Screws | Provide precise, low‑friction motion. | Directly impact positioning accuracy and repeatability. |

| Control System (CNC Controller) | Interprets G‑code and drives the machine axes. | User interface, programming flexibility, and integration with CAD/CAM software. |

| Tool Magazine / Automatic Tool Changer (ATC) | Stores multiple tools and swaps them automatically. | Reduces downtime and enables multi‑operation parts. |

| Worktable / Bed | Holds the workpiece; may be fixed or movable (Z‑axis). | Size and load capacity dictate the weight and dimensions of parts you can handle. |

| Coolant System | Delivers cutting fluid to the tool‑workpiece interface. | Improves tool life, surface finish, and chip evacuation. |

3. Key Technical Parameters

| Parameter | Typical Range | Description |

| Table size | 0.5 m × 0.5 m → 3 m × 2 m+ | Determines the maximum workpiece dimensions; large models can reach 3 m × 2 m. |

| Travel (X/Y/Z) | X ≈ 2000‑3000 mm, Y ≈ 1500‑2500 mm, Z ≈ 500‑800 mm | Corresponds to table size and defines the volume that can be machined in one setup. |

| Spindle power | 5 kW‑30 kW | Governs cutting capability and the hardness of materials that can be processed. |

| Spindle speed | 3000‑18000 rpm (variable) | High speeds suit aluminium/plastics; low speeds are for steel, titanium. |

| Tool magazine capacity | 12‑30 tools, automatic change | Auto‑tool change boosts productivity and reduces downtime. |

| Control system | Fanuc, Siemens, Mitsubishi, high‑end domestic CNC | Compatible with major CAD/CAM packages; supports 5‑axis or multi‑head configurations. |

| Accuracy | Position accuracy ±0.01 mm, repeatability ±0.005 mm | High precision for aerospace, mold‑making, and other demanding sectors. |

| Maximum workpiece weight | 500 kg‑2000 kg | Depends on bed rigidity and travel range. |

4. Key Buying Criteria

▸.Travel Dimensions – Measure the required X, Y, and Z travel for your largest part.

▸.Rigidity & Stability – Look for a robust gantry design (e.g., welded steel or cast iron) to minimize vibration.

▸.Spindle Power & Speed Range – Choose a spindle that can handle the materials you plan to mill (aluminum, steel, composites, etc.).

▸.Accuracy & Repeatability – Typical specs are expressed in microns; verify that they meet your tolerance requirements.

▸.Tool Capacity – Determine how many tools you need in the magazine; more tools mean fewer manual changes.

▸.Control Software Compatibility – Ensure the controller works with your preferred CAD/CAM package (Fusion 360, Mastercam, SolidWorks CAM, etc.).

▸.Ease of Maintenance – Look for accessible linear guides, sealed ball screws, and readily available spare parts.

▸.Safety Features – Emergency stop, interlocks, and proper guarding are essential.

▸.Service & Support – Consider the manufacturer’s warranty, on‑site service options, and training programs.

▸.Total Cost of Ownership (TCO) – Include initial purchase, installation, tooling, consumables, electricity, and maintenance over the machine's lifespan.

5. Typical Applications

| Industry | Example Parts | Why a Gantry Mill Is Preferred |

| Aerospace | Wing ribs, bulkheads, large brackets | Handles big, heavy components with high precision. |

| Automotive | Engine blocks, chassis components | Provides the travel needed for large castings. |

| Mold & Tooling | Injection molds, die plates | Rigid structure yields accurate cavity surfaces. |

| Marine | Propeller shafts, hull sections | Can machine large, dense materials like stainless steel. |

| Energy | Turbine blades, pump housings | Supports heavy, high‑tolerance parts. |

| Prototyping / R&D | Custom fixtures, experimental parts | Flexibility to switch tools and materials quickly. |

6. Advantages

•Large work area & high rigidity – ideal for big, heavy parts.

•High precision & repeatability – tight tolerances achievable.

•Flexibility – can handle many materials (metals, composites, plastics).

•Automation – ATC and CNC control reduce labor and cycle time.

•Scalability – suitable for prototype to low‑volume production.

7. Disadvantages / Trade‑offs

•High upfront cost – especially for high‑power spindles and large frames.

•Space & power demand – requires a dedicated shop floor area and robust electrical supply.

•Complex setup & programming – need skilled operators or CAM programmers.

•Material waste – milling removes material; nesting strategies are required to minimize scrap.

8. Buying Considerations

▸Define part size & material – set required travel, spindle power, and rigidity.

▸Select control system – ensure it supports your CAM software and optional 5‑axis add‑on.

▸Check machine footprint & foundation needs – gantry units need a stiff, level base.

▸Total Cost of Ownership – include machine price, installation, floor reinforcement, training, maintenance contracts, and energy consumption.

▸Request a trial run – ask the supplier to mill a sample part to verify accuracy and cycle time.

▸After‑sales support – confirm warranty length, spare‑part availability, and on‑site service response time.

9. Common Buyer Questions & Quick Answers

| Question | Short Answer |

| Do I need a coolant system? | Yes, for most metals; it reduces heat, improves finish, and extends tool life. |

| Can I run the machine 24/7? | With proper maintenance and a reliable cooling system, many shops operate continuously. |

| Is a 3‑axis gantry enough? | For flat or simple 3‑D parts, yes. Complex geometries may require a 4‑ or 5‑axis head. |

| Do I need an automatic tool changer? | If you run multi‑operation jobs or high‑volume production, an ATC saves time. |

| What software do I need? | A CAD program for design and a CAM package to generate G‑code; most controllers accept standard formats. |

| How much floor space is required? | Add at least 1‑2 feet around the machine for clearance, tooling, and maintenance access. |

| Can I upgrade the spindle later? | Many manufacturers offer modular spindle options; confirm compatibility before purchase. |

| What training is required? | Basic CNC programming, safety procedures, and routine maintenance; many vendors provide on‑site training. |

10. Installation & Setup Checklist

▸Site Preparation – Level concrete floor, adequate power (typically 380 V three‑phase), and proper ventilation.

▸Machine Positioning – Align the gantry with the room's axes; ensure enough clearance for tool changes and part loading.

▸Electrical Hook‑up – Follow the manufacturer’s wiring diagram; use a qualified electrician.

▸Coolant & Dust Extraction – Install a closed‑loop coolant system and a filtration unit to keep the work area clean.

▸Calibration – Perform a machine zeroing routine and verify axis travel limits.

▸Test Run – Run a simple program to confirm motion, spindle operation, and tool changes.

▸Documentation – Keep the user manual, wiring schematics, and maintenance log accessible.

11. Maintenance Best Practices

| Frequency | Task |

| Daily | Clean chips, check coolant level, inspect guards. |

| Weekly | Lubricate linear guides, inspect ball screws for wear. |

| Monthly | Verify axis backlash, run a test cut to check accuracy. |

| Quarterly | Replace coolant filters, check electrical connections. |

| Annually | Full alignment check, replace worn seals, update firmware. |

12. Typical Price Ranges (2025 market)

| Size | Approx. Price (CNY) |

| Small (≤ 1 m × 1 m) | 300 k – 500 k |

| Medium (1 m × 1.5 m) | 800 k – 1.5 M |

| Large (≥ 2 m × 2 m) | 2 M – 4 M |

| Ultra‑large/custom | > 5 M |

13. Evaluating Vendors

▸Reputation & Reviews – Look for case studies, customer testimonials, and industry awards.

▸After‑Sales Service – Availability of spare parts, response time, and on‑site support contracts.

▸Training Programs – On‑site or remote training for operators and programmers.

▸Customization Options – Ability to tailor the gantry size, spindle, or control system to your needs.

▸Financing & Leasing – Some vendors offer flexible payment plans or lease‑to‑own options.

14. Frequently Overlooked Details

•Grounding & Electrical Noise – Proper grounding reduces interference with the controller.

•Spindle Run‑Out – A well‑balanced spindle minimizes vibration and improves surface finish.

•Tool Holding System – Choose between ER, CAT, or HSK collets based on tool type and rigidity.

•Software Licensing – Verify whether CAM software licenses are perpetual or subscription‑based.

•Environmental Regulations – Ensure coolant disposal complies with local waste‑water rules.

15. Quick Reference Cheat Sheet

| Category | What to Look For |

| Travel | X ≥ required width, Y ≥ required length, Z ≥ required depth |

| Spindle | Power ≥ material hardness, speed range 5 k–30 k RPM |

| Accuracy | Positioning ≤ ±0.02 mm, repeatability ≤ ±0.01 mm |

| Tool Capacity | ≥ 12‑tool ATC for multi‑operation jobs |

| Control | User‑friendly UI, supports standard G‑code, Ethernet connectivity |

| Support | 24/7 hotline, on‑site technician within 48 h, spare parts inventory |

| Safety | Emergency stop, interlocked doors, overload protection |

16. Machine Types

•Bridge‑type gantry – spindle on a moving bridge (most common).

•Column‑type gantry – fixed spindle, moving table; used for very heavy workpieces.

17. Drive & Motion

•Linear motors / ball‑screw vs. rack‑and‑pinion – linear motors give higher speed, ball‑screws provide better rigidity.

•Servo‑controlled axes – essential for sub‑micron repeatability.

18. Cooling & Chip Management

•Built‑in flood coolant system (mist, through‑spindle, or external).

•Chip conveyors or vacuum extraction to keep work area clean.

19. Safety & Compliance

•Emergency stop, safety interlocks, ISO 12100/13849 compliance.

•Noise level (dB) and vibration specifications for workplace ergonomics.

20. Integration Options

•Robotic loading/unloading – for fully automated cells.

•In‑process inspection – probe stations or laser scanners can be mounted.

21. Upgradability

•Modular spindle upgrades (higher kW, higher RPM).

•Additional axes (4‑axis rotary table, 5‑axis head) for complex geometry.

22. Typical Lead Times

•Standard models: 4‑8 weeks.

•Custom‑size or high‑power options: 12‑20 weeks, depending on supplier capacity.

23. Financing & Leasing

•Many manufacturers offer leasing, rent‑to‑own, or equipment‑as‑a‑service (EaaS) plans to reduce upfront cost.

24. After‑Sales Support

•On‑site installation & training.

•Remote diagnostics via Ethernet/IoT.

•Spare‑part inventory and warranty extensions (1‑3 years).

25. ROI Calculation Tips

•Cycle time reduction vs. manual machining.

•Tool‑change time saved with ATC.

•Material utilization – nesting software can improve yield by 5‑15 %.

26. Frequently Compared Alternatives

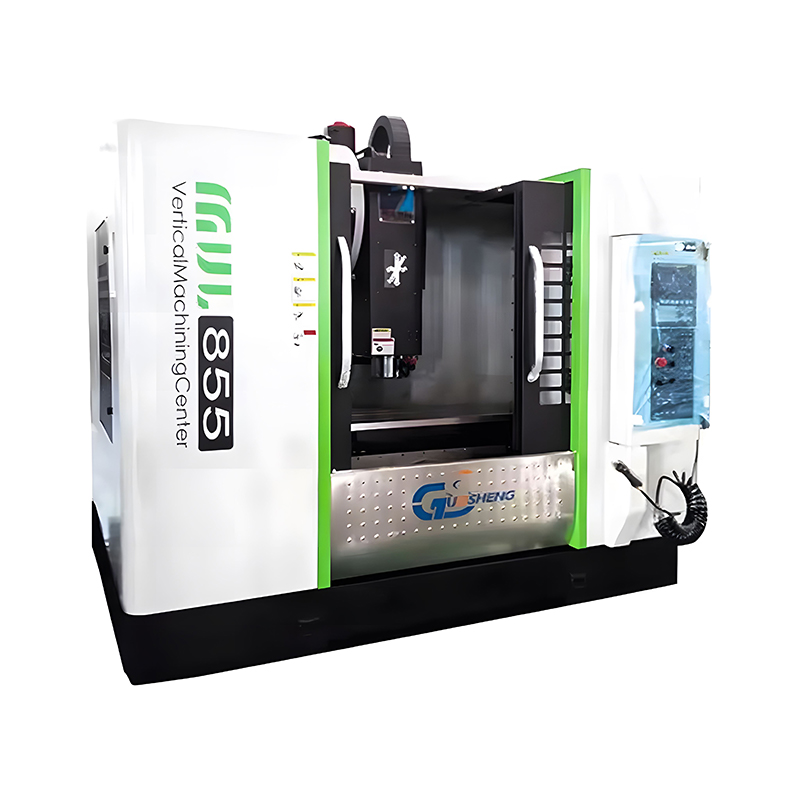

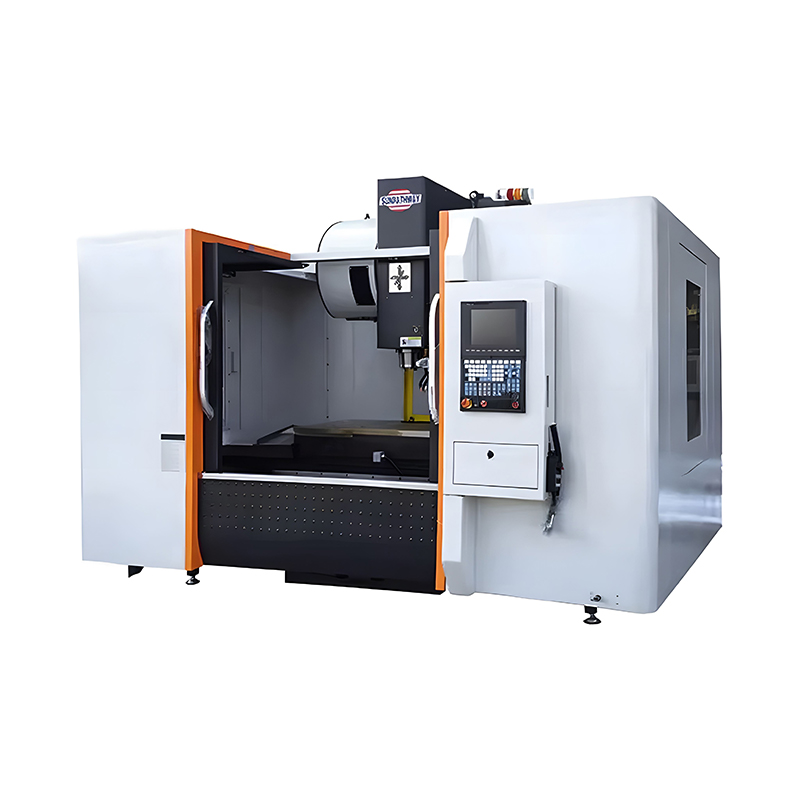

•Vertical CNC milling – smaller footprint, lower cost, limited workpiece size.

•Horizontal CNC milling – better for deep pockets, but less suitable for very large parts.

•5‑axis CNC machining centers – higher complexity, used when part geometry demands it.

27. Choosing the Right Axis Configuration

| Configuration | When It Fits |

| 3‑Axis (X‑Y‑Z) | Flat parts, simple pockets, drilling, and facing. |

| 4‑Axis (3‑Axis + A‑rotary) | Parts that need machining on multiple sides without re‑clamping (e.g., brackets, valve bodies). |

| 5‑Axis (3‑Axis + A & B‑rotary) | Complex aerospace or mold surfaces requiring simultaneous 3‑D contouring. |

28. Material Compatibility

| Material | Recommended Spindle Speed | Coolant Type |

| Aluminum | 12–20 k RPM | Water‑soluble coolant |

| Steel (mild) | 6–12 k RPM | Emulsion or oil‑based coolant |

| Stainless Steel | 4–8 k RPM | High‑pressure oil‑based coolant |

| Plastics / Composites | 12–24 k RPM | Minimal coolant, air blast optional |

29. Common Pitfalls & How to Avoid

| Issue | Cause | Prevention |

| Tool breakage | Excessive feed or wrong tool holder | Verify feeds, use proper collet |

| Poor surface finish | Vibration, dull tool | Check spindle run‑out, replace tool |

| Inaccurate dimensions | Lost steps, thermal drift | Regularly calibrate, allow machine to warm up |

| Coolant contamination | Improper filtration | Change filters per schedule |

30. Quick Decision Matrix

| Priority | Choose If | Recommended Feature |

| Cost‑sensitive | Low volume, simple parts | 3‑axis, basic spindle, manual tool change |

| High‑precision | Tight tolerances (< ±0.01 mm) | High‑grade linear guides, servo drives |

| Large‑format | Parts > 1 m in any axis | Extended gantry, heavy‑duty bed |

| Automation | Continuous production | ATC, pallet changer, integrated PLC |

31. Environmental Considerations

•Use water‑soluble coolant to simplify disposal.

•Install dust extraction to meet workplace air‑quality standards.

32. Energy Consumption Tips

•Power‑down spindle when idle.

•Use variable‑frequency drives for motor efficiency.

33. Remote Monitoring

•Enable controller's web interface.

•Set up alerts for temperature, spindle load, and axis errors.

34. Common Accessories

•Tool length measurement probe.

•Workpiece probing system for automatic zeroing.

•Pallet changer for batch production.

NEXT:Advantages of graphite carving and milling machine?

Interested in cooperation or have questions?

-

-

Operating a CNC machine is like flying a plane or performing surgery; although the movements become smooth with practice, even the slightest oversight can lead to costly losses. A checklist isn't meant to restrict your freedom, bu...

READ MORE -

Although many people recommend starting with simpler equipment, choosing a 5-axis CNC machine from the outset is actually a smart "one-step" strategy. For those who want to develop a long-term career in manufacturing, the advantag...

READ MORE -

Key Points to Consider Before Buying a CNC Machine Purchasing a CNC machine is a significant investment. Before making a decision, understanding the following points will help you choose the equipment best suited to your needs and...

READ MORE

-

Factory Address

Zhaxi Township Industrial Park, Nantong City, Jiangsu Province, China (west of Huaneng Power Plant)

-

Phone

+86-13615235768

+86-513-85632335

-

Fax

+86-513-85632766

-

Email

pan.director@sunwayer.com

lf you can't find the answer you're looking for, chat with our friendly team.

русский

русский Español

Español