-

VIEW MORE

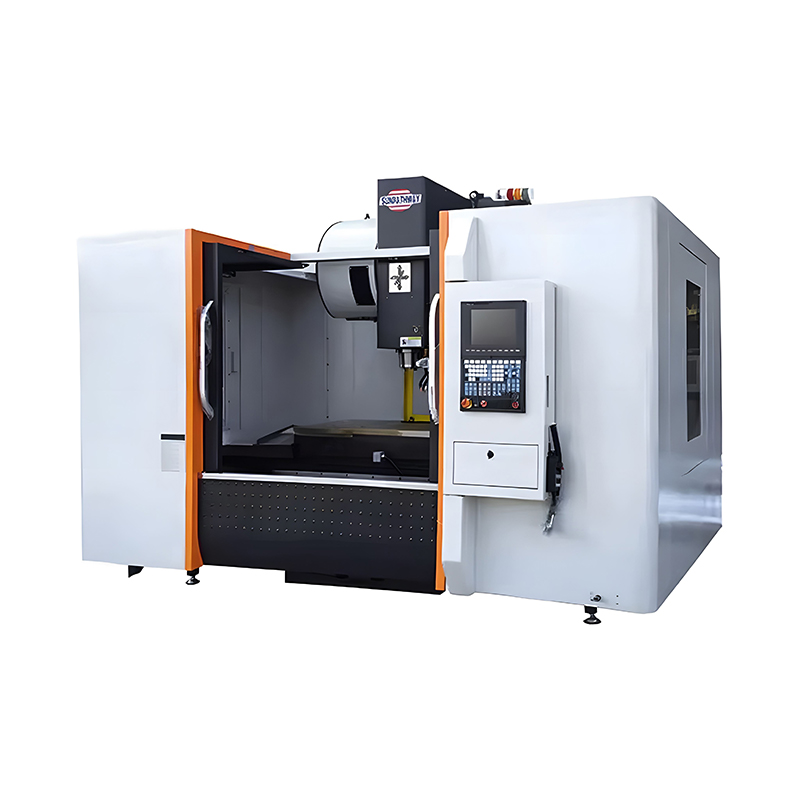

VMC850L High Speed 3 Axis CNC Vertical Machining Center

The VMC850L High-Speed 3-Axis CNC Vertical Machining Center is a high-performance milling machine de...

VIEW MORE

VMC850L High Speed 3 Axis CNC Vertical Machining Center

The VMC850L High-Speed 3-Axis CNC Vertical Machining Center is a high-performance milling machine de...

-

VIEW MORE

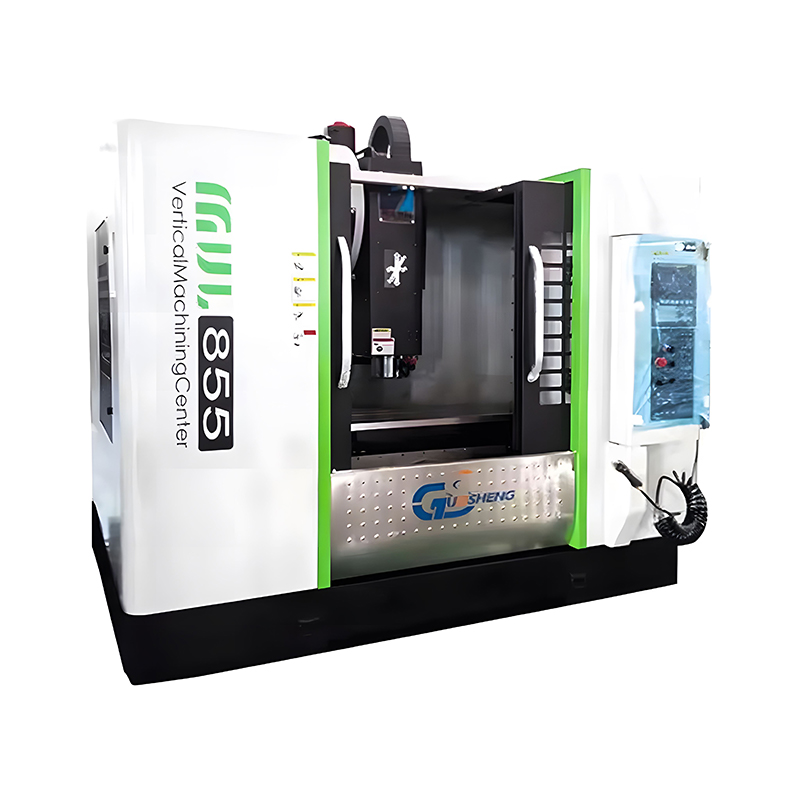

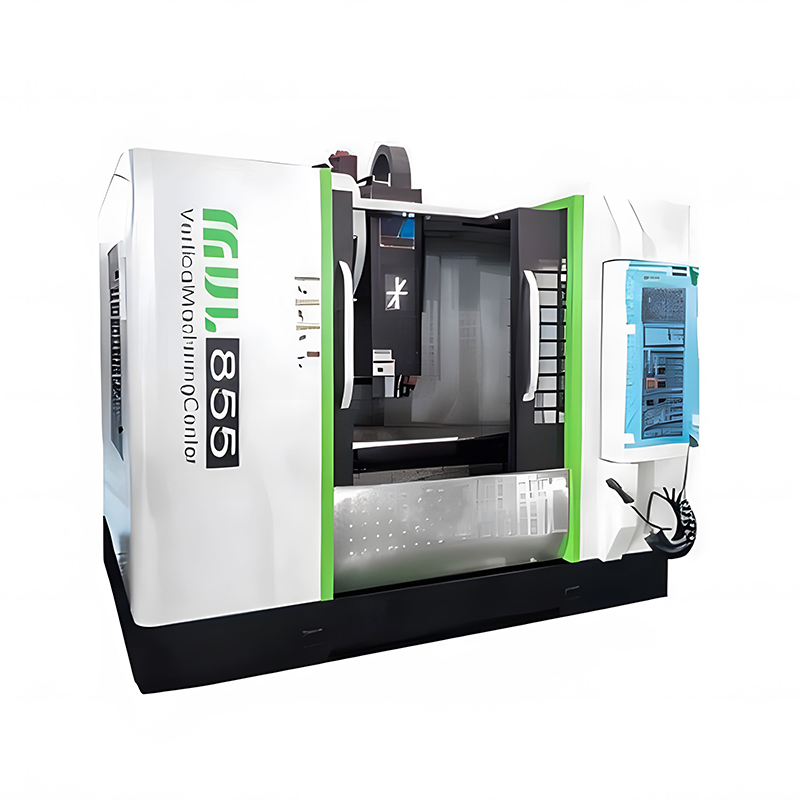

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

VIEW MORE

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

-

VIEW MORE

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

VIEW MORE

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

-

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

-

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

This machine tool inherits the advantages of traditional vertical CNC milling machines, such as strong rigidity of the basic frame, symmetrical structure, and strong stability, and introduces the internationally advanced dynamic rigidity design concept, and optimizes the design of moving parts. The machine tool has large torque and good rapid response characteristics, and is suitable for the needs of various mechanical processing fields such as automobiles, molds, aerospace, military industry, hardware, etc.

русский

русский Español

Español