In industrial manufacturing, 3-axis CNC electrical discharge machines (EDMs) are precision machining equipment widely used in mold making and complex parts processing. Nantong Sunway Science and Technology Development Co., Ltd. specializes in providing clients with consulting services for equipment upgrades and function expansions, customized maintenance plans to accommodate flexible schedules, and retraining services for new operators. These services ensure the long-term, efficient operation of the equipment and enhance the professional competence of operators.

Question 1: What is the basic principle of a 3-axis CNC EDM?

•A 3-axis CNC EDM utilizes the principle of electrical spark discharge to remove material, using a computer numerical control system to precisely control motion along three axes to achieve high-precision machining.

•This technology relies on a spark gap between the electrode and the workpiece, generating high-temperature erosion in a non-contact state, thereby preventing mechanical stress from damaging the workpiece.

•The machining process involves complex electrical parameter adjustments, including pulse width and frequency settings, to ensure uniform material removal and a smooth surface finish.

•In our equipment upgrade consultations, Nantong Sunway Science and Technology Development Co., Ltd. often helps clients optimize these parameter settings to suit the machining requirements of different materials and improve overall efficiency.

Question 2: What are the main applications for 3-axis CNC EDM machines?

•In the mold manufacturing industry, this equipment is often used to machine carbide or hardened steel molds, achieving precise forming of complex cavities and microstructures.

•The aerospace and automotive manufacturing sectors rely on this technology to process high-strength materials, such as turbine blades or gear components, ensuring dimensional accuracy and surface integrity.

•In medical device production, 3-axis CNC EDM machines are suitable for manufacturing precision implants or surgical tools. Their non-contact nature reduces the risk of damage to biocompatible materials.

•With Nantong Sunway Science and Technology Development Co., Ltd.'s feature expansion services, companies can customize the machine's features, such as adding automated loading systems, to expand its application in mass production.

Question 3: What are the core advantages of using a 3-axis CNC EDM machine?

•High-precision machining capabilities are a significant advantage of this machine, enabling micron-level dimensional control and suitable for reproducing exacting geometries.

•The machining process generates no cutting forces, preventing workpiece deformation or cracking, making it particularly suitable for processing brittle materials or thin-walled structures. The machine's versatility allows machining of a variety of conductive materials, including carbide, titanium alloys, and ceramic composites, without the need for tool changes.

•Nantong Sunway Science and Technology Development Co., Ltd. ensures these advantages are maintained over time through customized maintenance plans, such as regular system calibration to prevent accuracy drift.

Question 4: What key factors should be considered when operating a 3-axis CNC EDM machine?

•Operators must master electrical parameter setting techniques, including spark gap control and electrode wear compensation, to prevent machining anomalies or equipment damage.

•Safety regulations emphasize isolating high-voltage electrical systems and regularly checking coolant circulation systems to avoid overheating or fire risks.

•Workpiece clamping and positioning must be precise; otherwise, machining errors or electrode collisions can occur, impacting overall production efficiency.

•Nantong Sunway Science and Technology Development Co., Ltd. offers retraining services for new operators, covering these practical points and strengthening skills through simulation exercises to shorten the learning curve.

Question 5: What are the key maintenance aspects of a 3-axis CNC EDM machine?

•Routine maintenance involves cleaning the work area and electrode system, and removing machining residues to maintain stable spark discharge.

•Key components such as servo motors and guideways require regular lubrication and calibration to ensure accurate axial motion and prevent wear-related loss of accuracy.

•Electronic control system diagnostics include checking the pulse power supply and CNC unit to identify potential faults and avoid unexpected downtime that could impact production schedules.

•Nantong Sunway Science and Technology Development Co., Ltd.'s customized maintenance service plans are designed to suit the customer's production schedule, providing flexible on-site service and ensuring maintenance does not disrupt normal operations.

Question 6: How can I upgrade and expand the functionality of a 3-axis CNC EDM machine?

•Functional upgrades may include integrating advanced CNC software to enhance path programming capabilities or enable multi-tasking machining, increasing the machine's intelligence.

•Expansion options involve adding accessories such as rotary axes or in-line detection systems to adapt the machine to more complex 5-axis machining requirements and expand its application range.

•The upgrade process requires evaluating existing equipment compatibility to avoid performance degradation due to hardware conflicts. Nantong Sunway Science and Technology Development Co., Ltd.'s equipment upgrade consulting services provide professional assessments to help clients select the optimal solution and ensure seamless integration of upgraded equipment into production lines.

Question 7: What are the industry trends for 3-axis CNC EDM machines?

•Current trends focus on automation and intelligent integration, such as integrating robotic loading and unloading systems to achieve unmanned machining and improve production efficiency.

•Environmental factors are driving technological innovation, such as the use of energy-saving pulse power supplies and recyclable coolant to reduce resource consumption and environmental impact.

•Industry standards are shifting towards higher precision and faster response, requiring equipment to include real-time monitoring and adaptive control capabilities.

•Nantong Sunway Science and Technology Development Co., Ltd. closely monitors these trends in its services, updating operator knowledge through retraining courses to ensure clients' equipment remains at the forefront of the industry.

VIEW MORE

CNC-430 Small CNC Electrical Discharge Machine for Metal Mould Making

The CNC-430 is a computer-controlled electrical discharge machining system optimized for small-scale...

VIEW MORE

CNC-430 Small CNC Electrical Discharge Machine for Metal Mould Making

The CNC-430 is a computer-controlled electrical discharge machining system optimized for small-scale...

VIEW MORE

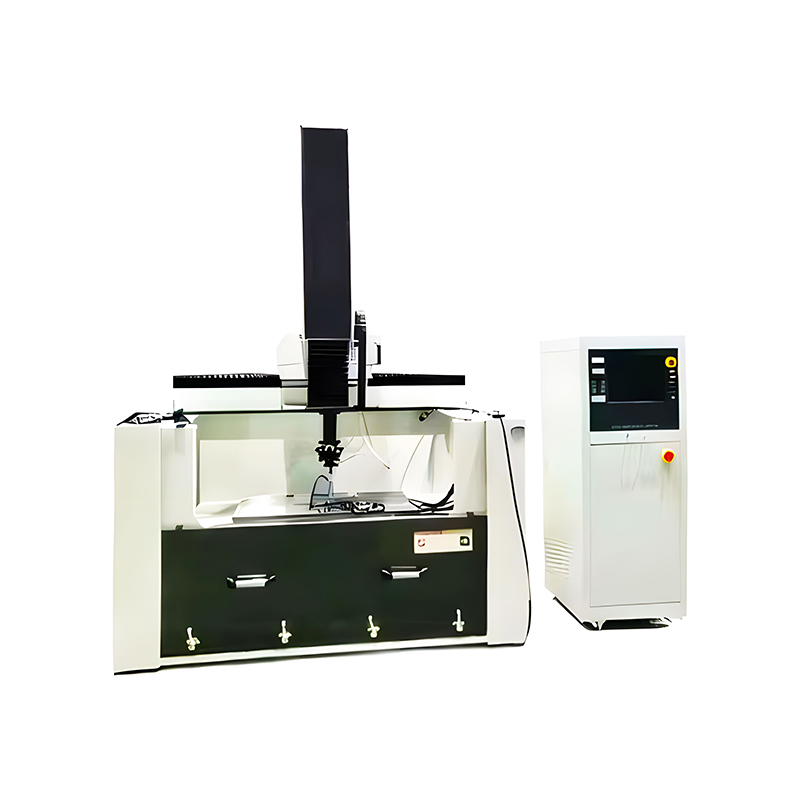

CNC-OX540 3 Axis CNC EDM Die Sinking Machine

The CNC-OX540 3-Axis CNC EDM die sinking machine is engineered for controlled electrical discharge m...

VIEW MORE

CNC-OX540 3 Axis CNC EDM Die Sinking Machine

The CNC-OX540 3-Axis CNC EDM die sinking machine is engineered for controlled electrical discharge m...

VIEW MORE

CNC-OX650 3 Axis CNC EDM CNC Machine Tool

The CNC-OX650 3-Axis CNC EDM Machine Tool is designed for precision electrical discharge machining (...

VIEW MORE

CNC-OX650 3 Axis CNC EDM CNC Machine Tool

The CNC-OX650 3-Axis CNC EDM Machine Tool is designed for precision electrical discharge machining (...

VIEW MORE

CNC-OX850 3-Axis CNC Die Sinker EDM with Digital Control

The CNC-OX850 is a 3-axis CNC die sinker EDM designed for precision machining of conductive material...

VIEW MORE

CNC-OX850 3-Axis CNC Die Sinker EDM with Digital Control

The CNC-OX850 is a 3-axis CNC die sinker EDM designed for precision machining of conductive material...

русский

русский Español

Español