For beginners, the ideal CNC machine isn't necessarily the most powerful one, but rather the one that makes you "confident enough to get started" and has a "high tolerance for errors." Here are a few types of machines su...

READ MORECNC-OX850 3-Axis CNC Die Sinker EDM with Digital Control

Application scenarios and scope of application

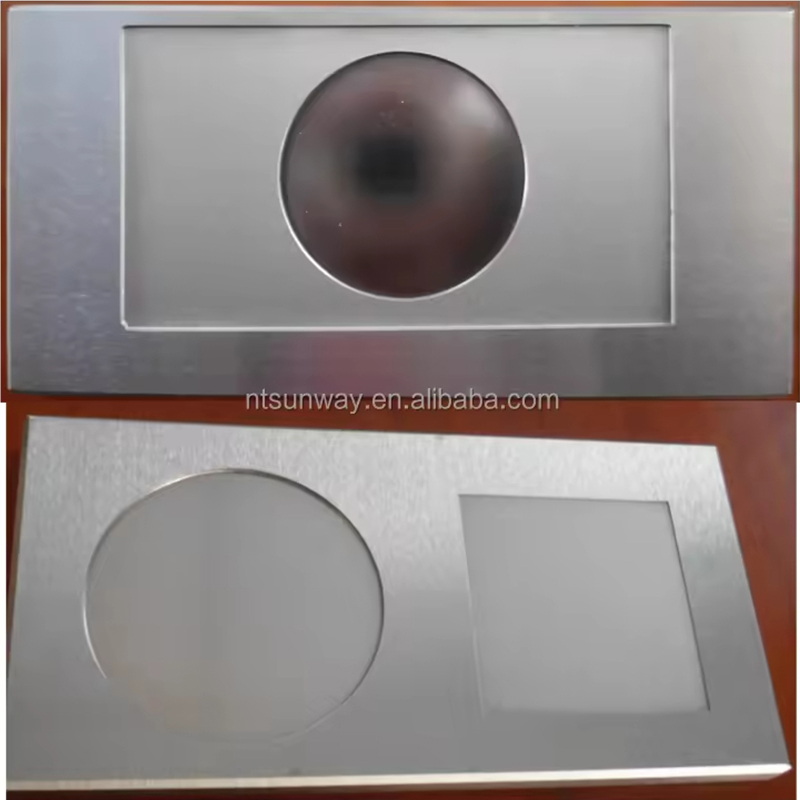

Mold Manufacturing: Production of injection molds, stamping dies, and forging dies.

Aerospace & Automotive: Machining hardened alloys and intricate components.

Tool & Die Making: Fabrication of extrusion dies and precision tooling.

Medical & Electronics: Processing small, high-detail parts with tight tolerances.

Description

Contact us

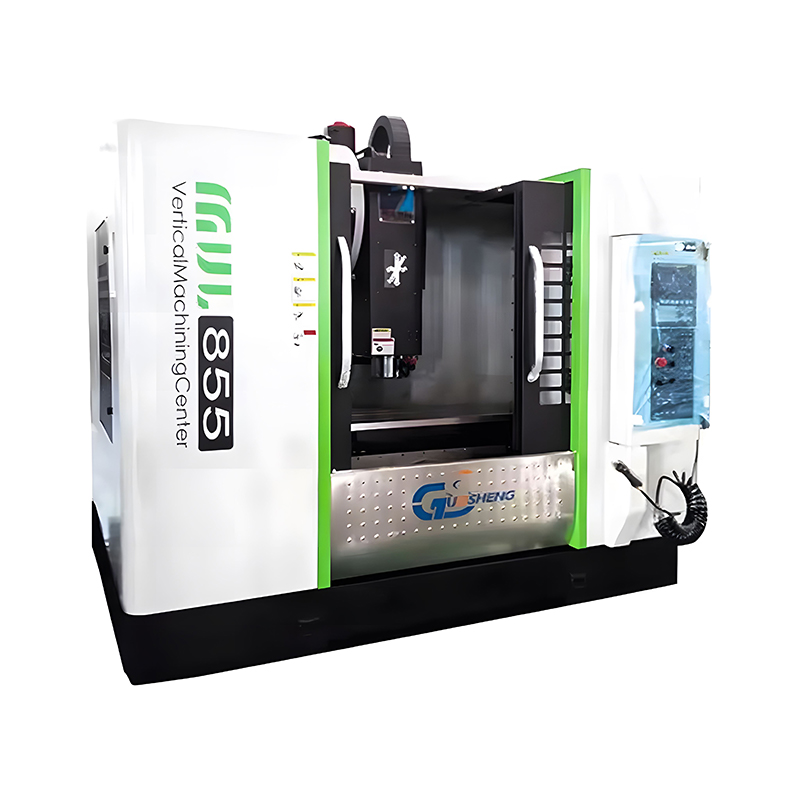

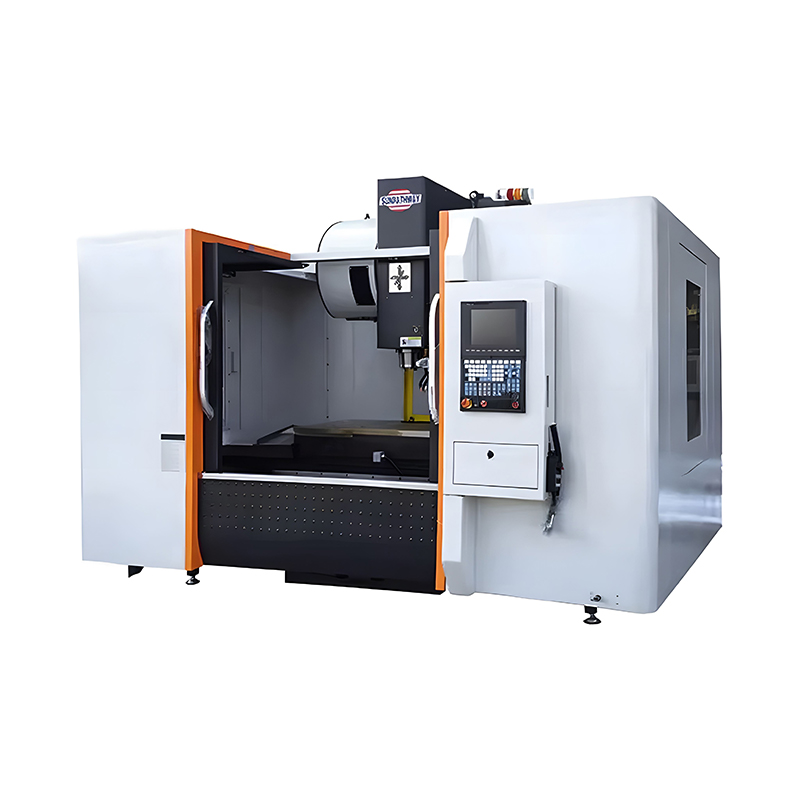

The CNC-OX850 is a 3-axis CNC die sinker EDM designed for precision machining of conductive materials. Equipped with digital control technology, it ensures stable discharge machining with efficient electrode wear compensation. The machine is suitable for manufacturing complex cavities, molds, and intricate geometries where conventional cutting methods are ineffective.

Product Features/Advantages

3-Axis CNC Control: Enables automated movement along X, Y, and Z axes for consistent machining.

Digital Pulse Generation: Adjustable discharge parameters for optimized surface finish and material removal.

Electrode Wear Compensation: Automatically corrects tool wear to maintain dimensional accuracy.

Rigid Construction: Heavy-duty frame ensures stability during high-intensity discharge operations.

User-Friendly Interface: Simplified programming and real-time monitoring for efficient operation.

The CNC-OX850 integrates advanced EDM technology with reliable performance, making it suitable for industrial applications requiring intricate shaping of conductive materials.

Specification

| Model | OX-430 (450) | OX-540 | OX-650 | OX-850 | OX-1060 | |

| Work surface size (mm) (length × width) | mm | 700×400 | 850×500 | 900×650 | 1100×650 | 1250×800 |

| Left and right travel (X axis) | mm | 450 | 500 | 600 | 850 | 1000 |

| Front and rear travel (Y axis) | mm | 350 | 400 | 450 | 500 | 600 |

| Spindle travel (Z axis) | mm | 300 | 300 | 400 | 400 | 500 |

| The distance from the lower end of the T-slot plate to the work surface | mm | 320-620 | 370-670 | 370-770 | 500-900 | 500-1000 |

| Oil tank inner cavity dimensions (length × width × height) | mm | 1200×700×440 | 1440×800×500 | 1616×950×550 | 1800×1100×600 | 2100×1250×600 |

| Fuel tank capacity | L | 703 | 828 | 1177 | 1340 | 1960 |

| Maximum electrode weight | mm | 100 | 120 | 150 | 200 | 400 |

| Workbench load-bearing | kg | 1000 | 1800 | 2500 | 3000 | 3500 |

| Machine weight | kg | 2500 | 3300 | 3500 | 4500 | 6500 |

| Unit price | yuan | 70000 | 83000 | 92000 | 104000 | 140000 |

We can provide you with a satisfactory plan!

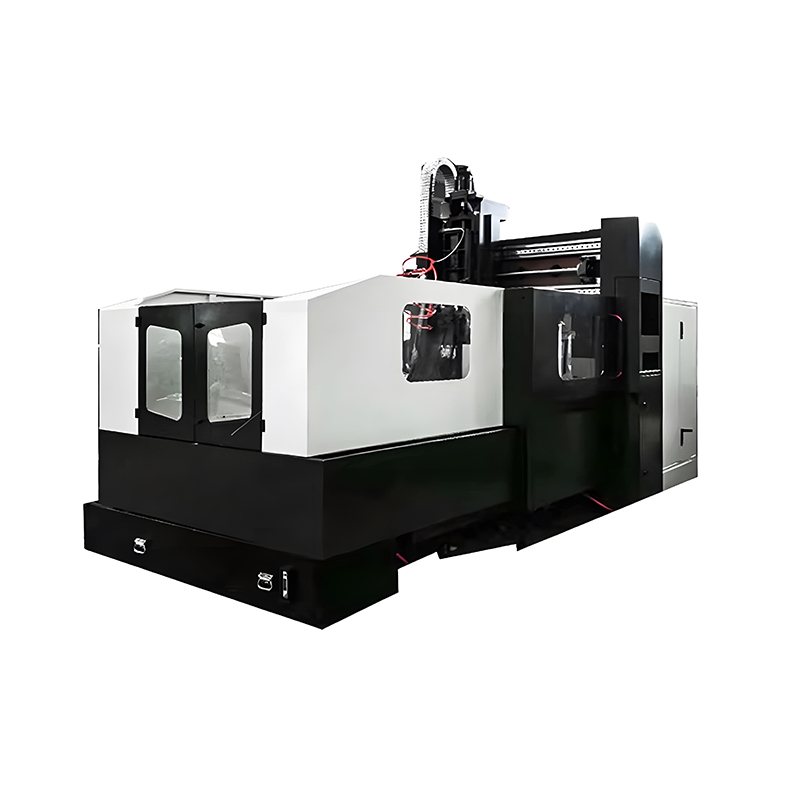

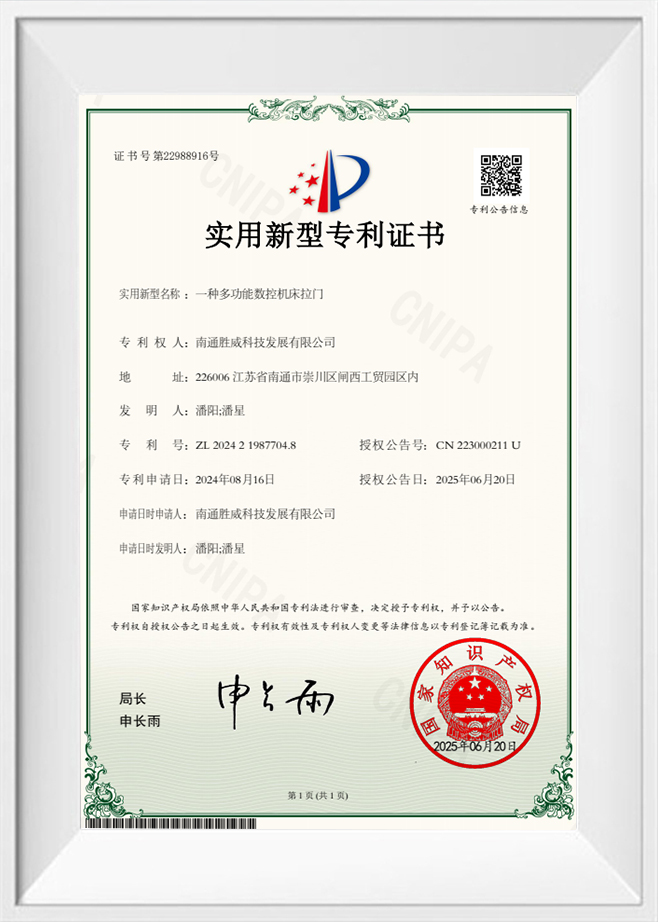

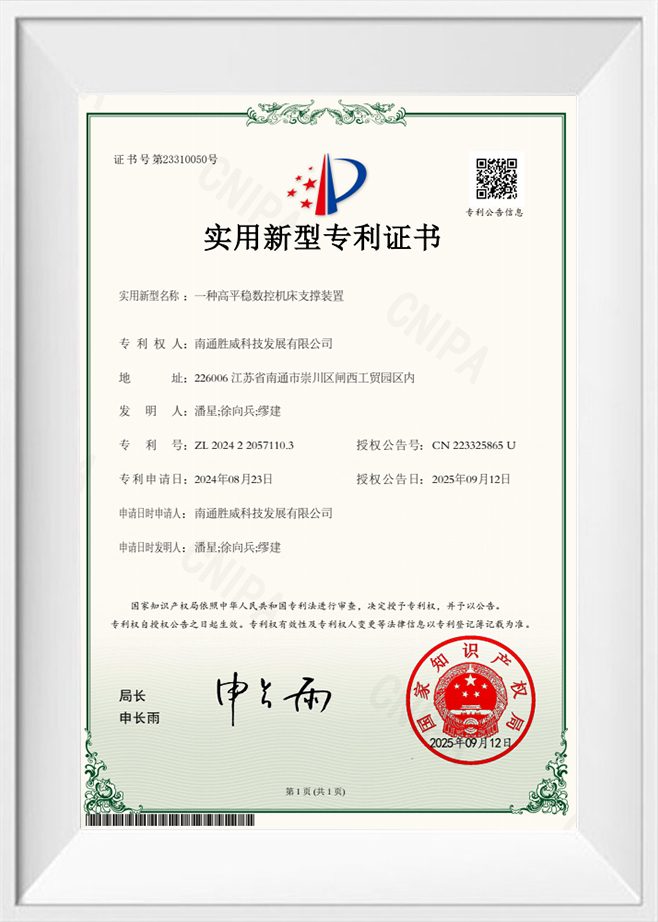

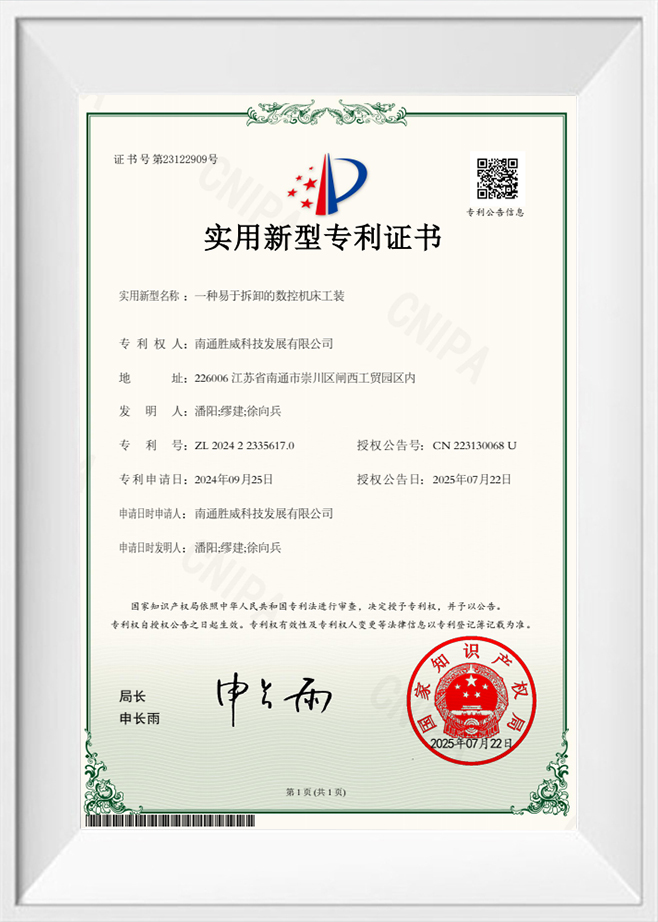

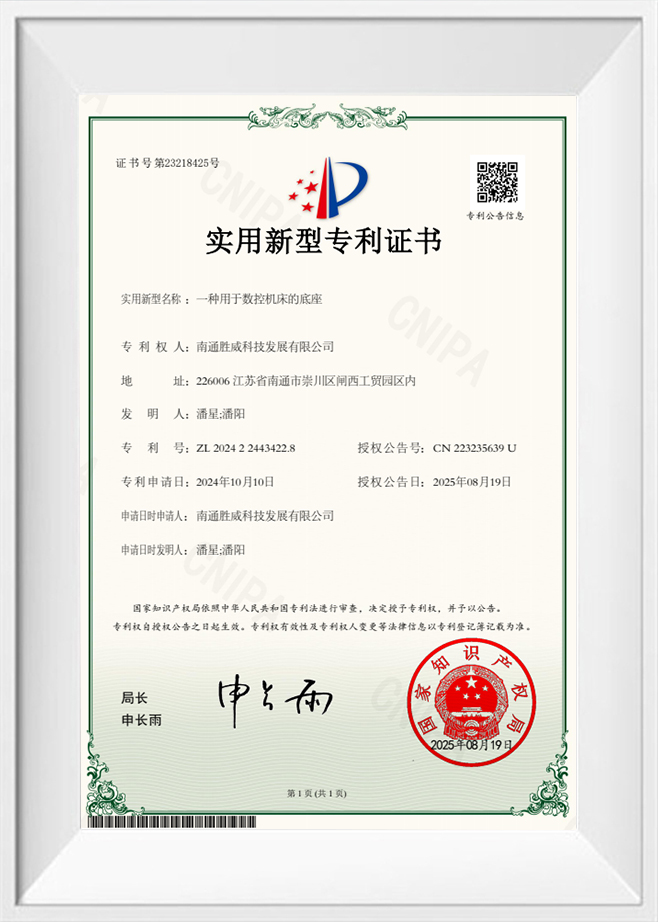

Since its establishment, Sunway has continuously increased investment in basic manufacturing and technical equipment. It has built a high-standard foundry and a large structural part processing factory covering an area of approximately 10000 square meters, and introduced multiple advanced guideway grinders and precision processing equipment, forming independent processing and assembly capabilities from structural parts to complete machines.

Sunway has always adhered to the business philosophy of "being honest, pursuing excellent quality, working diligently, and developing through innovation". It attaches great importance to the ex-factory quality of each piece of equipment, strictly implements the testing process, and strives to deliver each product with stability and reliability. With stable performance and good service, Sunway products have not only won customer praise in China but also been exported to Europe, America, Southeast Asia, and other regions.

We believe that high-quality products stem from down-to-earth accumulation. In the future, Sunway will continue to invest in process optimization, intelligent control, customer customization, and other directions, and strive to become your trustworthy machinery and equipment manufacturing partner for a long time.

-

-

Operating a CNC machine is like flying a plane or performing surgery; although the movements become smooth with practice, even the slightest oversight can lead to costly losses. A checklist isn't meant to restrict your f...

READ MORE -

Although many people recommend starting with simpler equipment, choosing a 5-axis CNC machine from the outset is actually a smart "one-step" strategy. For those who want to develop a long-term career in manufacturing, th...

READ MORE -

Key Points to Consider Before Buying a CNC Machine Purchasing a CNC machine is a significant investment. Before making a decision, understanding the following points will help you choose the equipment best suited to your...

READ MORE

русский

русский Español

Español