-

VIEW MORE

CNC-430 Small CNC Electrical Discharge Machine for Metal Mould Making

The CNC-430 is a computer-controlled electrical discharge machining system optimized for small-scale...

VIEW MORE

CNC-430 Small CNC Electrical Discharge Machine for Metal Mould Making

The CNC-430 is a computer-controlled electrical discharge machining system optimized for small-scale...

-

VIEW MORE

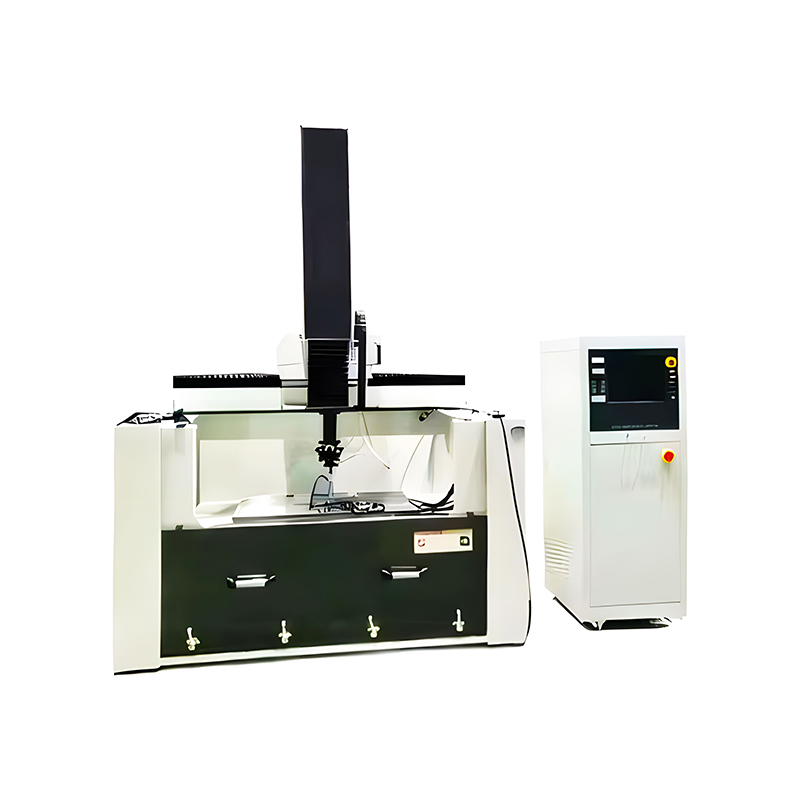

CNC-OX540 3 Axis CNC EDM Die Sinking Machine

The CNC-OX540 3-Axis CNC EDM die sinking machine is engineered for controlled electrical discharge m...

VIEW MORE

CNC-OX540 3 Axis CNC EDM Die Sinking Machine

The CNC-OX540 3-Axis CNC EDM die sinking machine is engineered for controlled electrical discharge m...

-

VIEW MORE

CNC-OX650 3 Axis CNC EDM CNC Machine Tool

The CNC-OX650 3-Axis CNC EDM Machine Tool is designed for precision electrical discharge machining (...

VIEW MORE

CNC-OX650 3 Axis CNC EDM CNC Machine Tool

The CNC-OX650 3-Axis CNC EDM Machine Tool is designed for precision electrical discharge machining (...

-

VIEW MORE

CNC-OX850 3-Axis CNC Die Sinker EDM with Digital Control

The CNC-OX850 is a 3-axis CNC die sinker EDM designed for precision machining of conductive material...

VIEW MORE

CNC-OX850 3-Axis CNC Die Sinker EDM with Digital Control

The CNC-OX850 is a 3-axis CNC die sinker EDM designed for precision machining of conductive material...

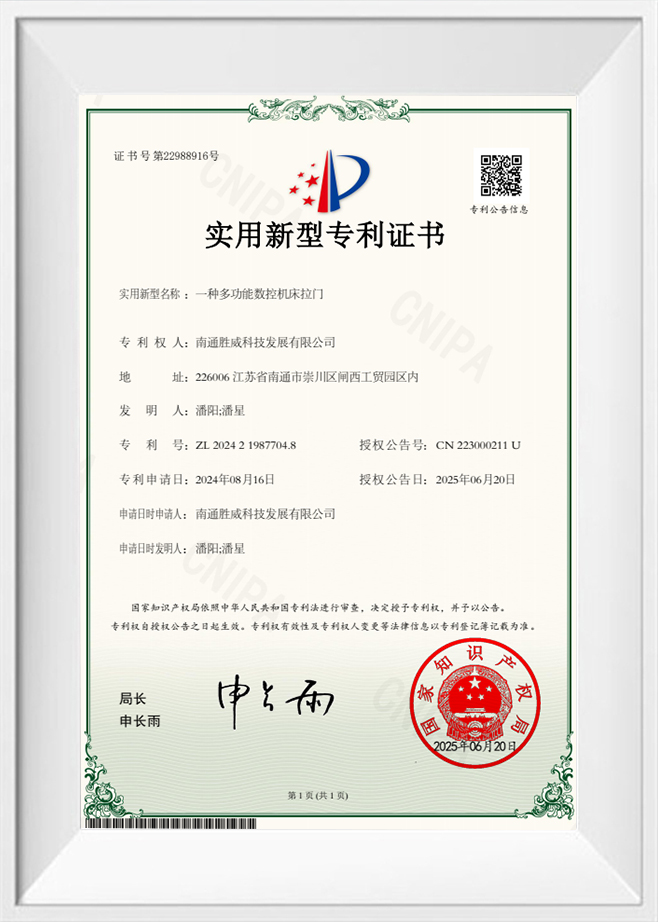

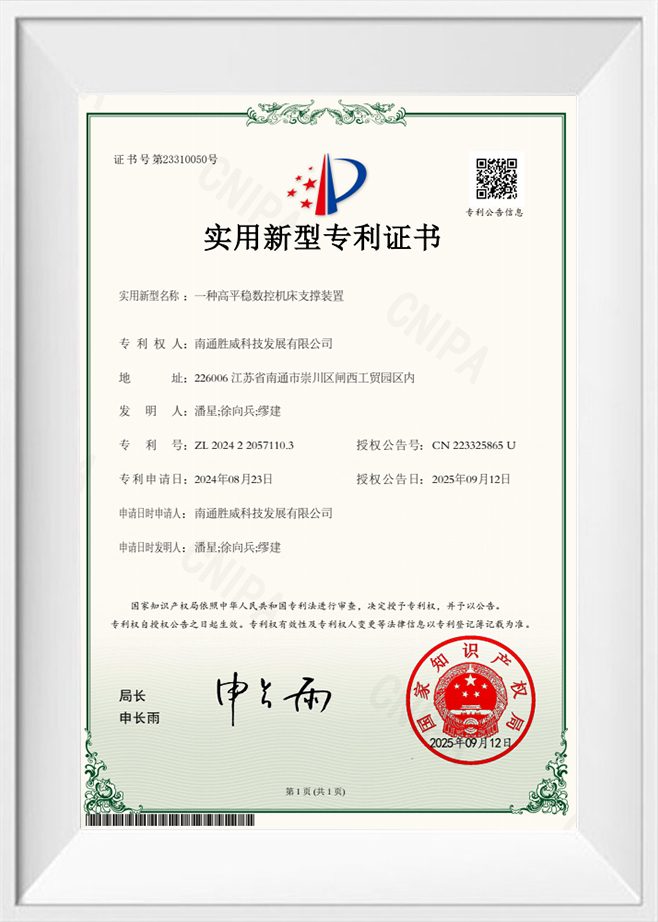

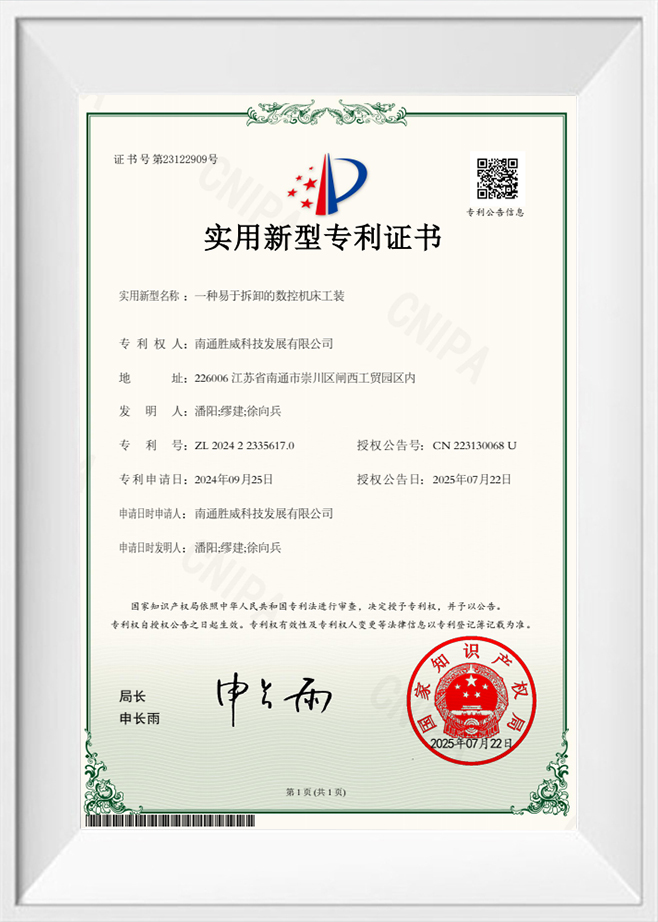

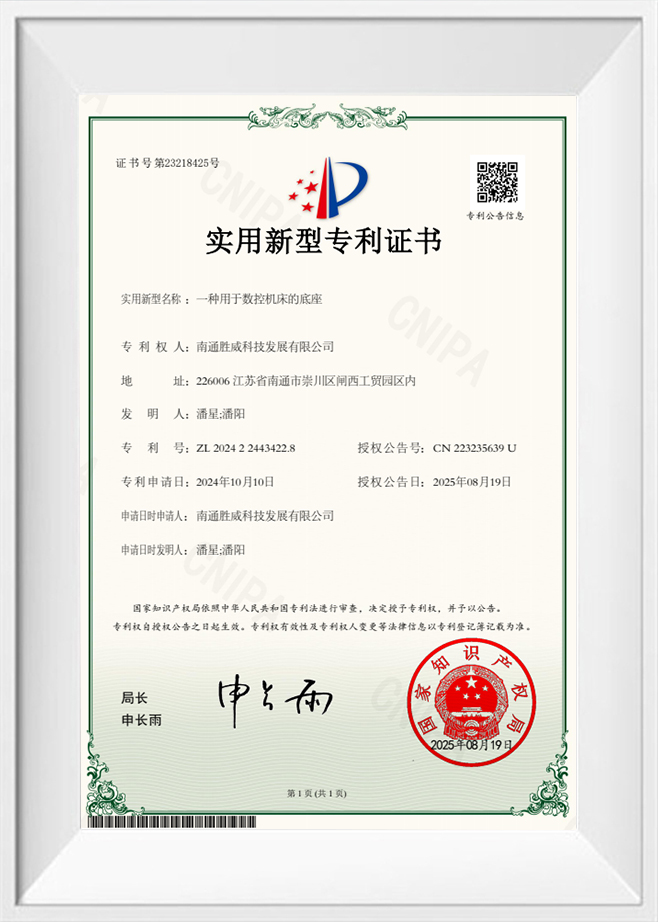

Brief Introduction We have produced electric spark shaping mills from ZNC-SW350 to SW650, axis numerical control standard type, and three-axis numerical control CNC-450, 540, 640……1060 to CNC OX-2180 OX-head type variety electrical spark shaping mills, all machine tools are designed according to international standards. On quality control, from high grade casting(we are the only company who exports to German DMG) to the last ground finish on imported equipment, with hand scraping, each accuracy error is less than 0.01mm, equip with high efficient and stabilize control machining of Taiwan electrical control cabinet, its excellent low loss and high smooth finish is the important difference from other EDM machine. Our EDM machine tools can discharge machining all kinds of plastic moulds and high precision IC moulds.

We have more than 40 types of machine tools, and also optimize our design through 5-10. We have exported for more than 10 years, including South Korea, Russia, Turkey, Italy, Switzerland, Pakistan, the Philippines, and twelve other countries. No field service and complaint, and all our customers become our long-term cooperation partners.“Quality, price, service” are our company development elements. We get our customers' favor by our punctilious work attitude. We have detailed control rules on purchasing、machining、assembling, and technology craft, and strict examination and examination standard (60% of Japanese of JIS and European precision standard as standard), and high-quality employees who do every detail well. Our goal is “to be the best”.

Based on made in China reasonable price, and design high-quality machine tools for customers according to the Japanese (JIS) standard, expand and R&D new products, improve the usage experience of our customers, and create immense value for customers.

Our company's obedience are” integrity,y morality, quality standard, diligence, efficiency, innovative development”, we are devoted to “zero defect” high-quality products for more customers by our professional spirit, professional manufacture, and strict scientific standard to manage.

русский

русский Español

Español