-

VIEW MORE

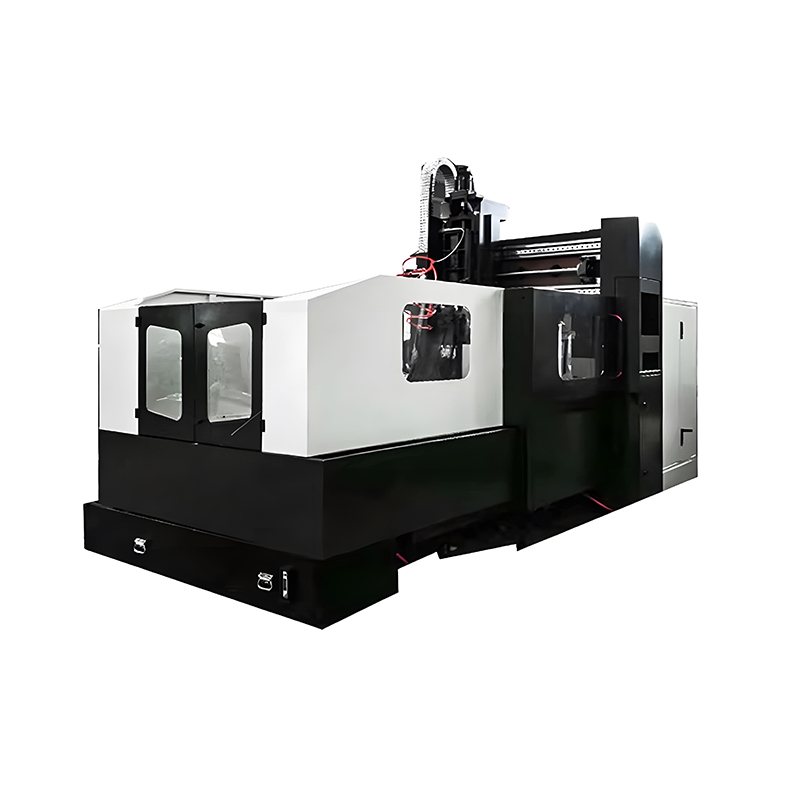

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

VIEW MORE

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

-

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

-

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

-

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

-

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

-

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

The CNC high-speed gantry machining center is a high-precision, high-efficiency machine tool that adopts an advanced CNC system and a rigid gantry structure. It has excellent dynamic performance and stability and is suitable for high-speed, high-precision machining of large and complex parts. Its large-stroke worktable, high-speed spindle, and fast feed system can meet the stringent machining requirements of industries such as aerospace, automotive molds, and energy equipment. It is also equipped with intelligent functional modules, such as automatic tool change systems and online detection, which significantly improve production efficiency and machining quality. It is the core equipment of modern intelligent manufacturing.

русский

русский Español

Español