-

VIEW MORE

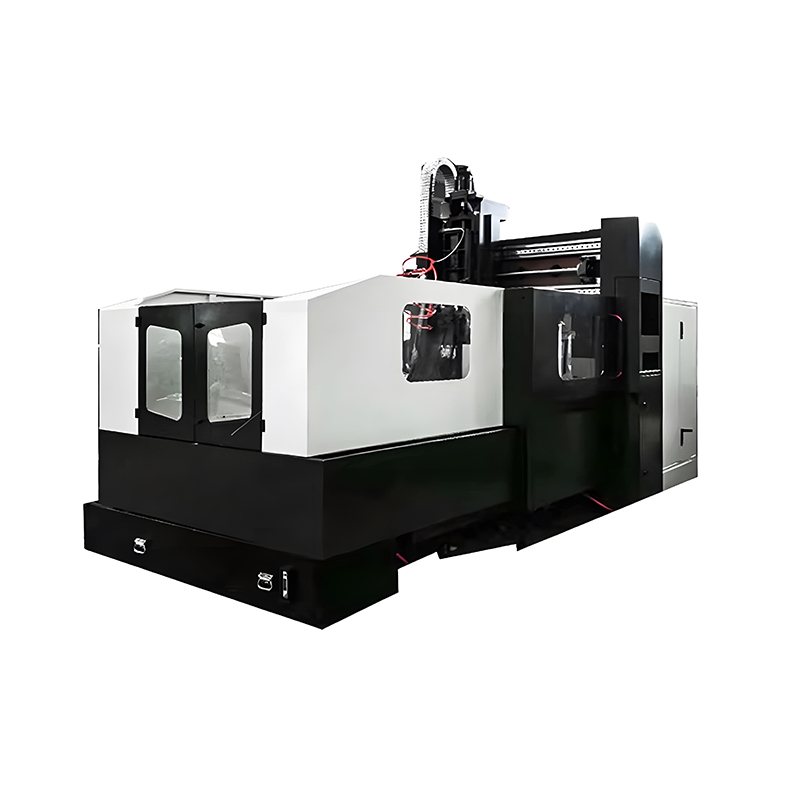

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

VIEW MORE

LM-1090 CNC Milling Gantry Type Machine

The LM-1090 represents a structural-class CNC gantry mill engineered for demanding material removal ...

-

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

VIEW MORE

LM-1311 4 Axis CNC Gantry Engraving Machine

The LM-1311 4-Axis CNC Gantry Engraving Machine is designed for multi-dimensional machining tasks, i...

-

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

VIEW MORE

LM-1609 5 Axis CNC Gantry Milling Machine

The LM-1609 5-Axis CNC Gantry Milling Machine is designed for complex machining tasks requiring mult...

-

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

VIEW MORE

LM-1613 High Precision Metal Milling Gantry CNC Machine

The LM-1613 is a heavy-duty gantry CNC milling machine designed for demanding metalworking applicati...

-

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

VIEW MORE

LM-1814 Gantry Type CNC Milling Machine Controller

The LM-1814 is a dedicated CNC controller engineered for gantry-type milling machines, offering prec...

-

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

VIEW MORE

LM-2011 CNC Gantry Milling Machine

The LM-2011 is a heavy-duty CNC gantry milling machine built for large-scale workpiece machining. It...

Main structure

The machine tool has a gantry frame fixed and a movable worktable structure, which is mainly composed of a worktable, a bed, a column, a crossbeam, a saddle, a ram, a hydraulic system, a lubrication system, a cooling and filtering system, a chip removal device, a rotary operation panel and an electronic control system.

X-axis: The worktable moves forward and backward in the longitudinal direction of the bed; X-axis: The worktable moves forward and backward in the longitudinal direction of the bed.

Y-axis: The ram and saddle components on the crossbeam move horizontally left and right along the guide rail.

Z-axis: The slider moves vertically up and down along the guide rail on the slide.

Column

Material: high-strength cast iron, resin sand molding.

Hydraulic system

The hydraulic system functions include automatic spindle clamping, etc. The system adopts an integrated installation to ensure the reliability of the whole machine operation and convenient maintenance.

Lubrication system

The guide rails and screws of the whole machine adopt the booster centralized timed quantitative lubrication system, and the oil circuit adopts advanced booster metering components for oil control; whether the oil supply cycle and oil supply amount of each lubrication point can be adjusted, and the actual control is carried out through the electrical system

Now it is fully automatic centralized lubrication. The spindle bearings and screw bearings are lubricated with high-grade special lithium grease.

Cooling system

Two tool cooling systems, a cutting fluid unit, and a cutting air blowing unit are standardly equipped.

Automatic chip removal system

A set of spiral chip conveyors is installed on both sides of the workbench, and a lifting chain chip conveyor is installed at the end of the machine.

Other configuration instructions

1. The working area is illuminated to adapt to night work.

2. The machine is equipped with a three-color light to prompt three kinds of information: program running, work cycle completion, and fault alarm.

3. The bed is shielded by a stainless steel plate, and the crossbeam is shielded by an accordion.

русский

русский Español

Español