-

VIEW MORE

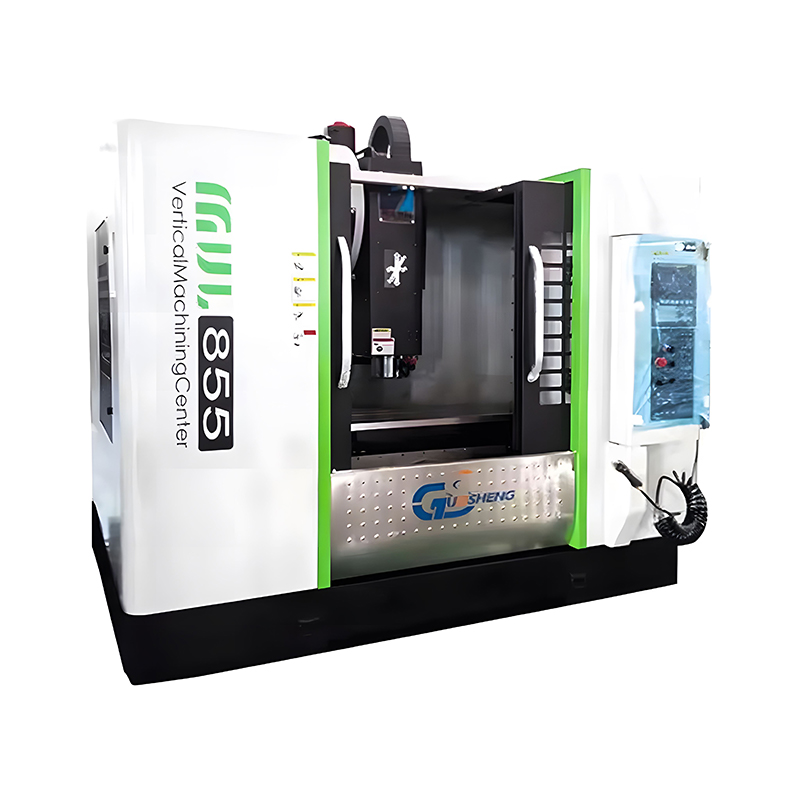

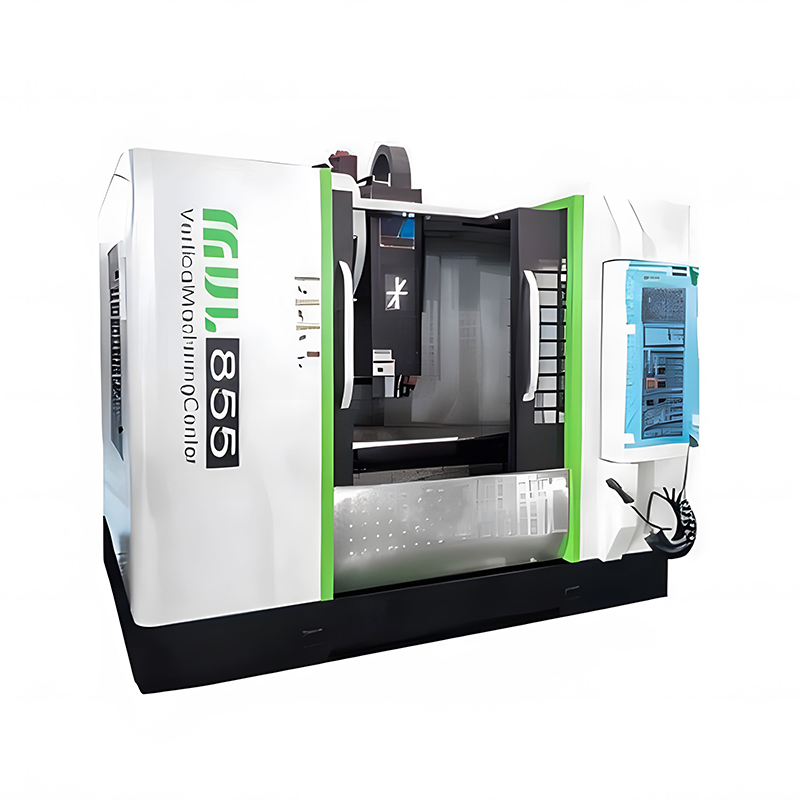

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

VIEW MORE

VMC-855 Hard Rail High Speed Vertical Machining Center

The VMC-855 is a rigid, high-speed vertical machining center designed for efficient material removal...

-

VIEW MORE

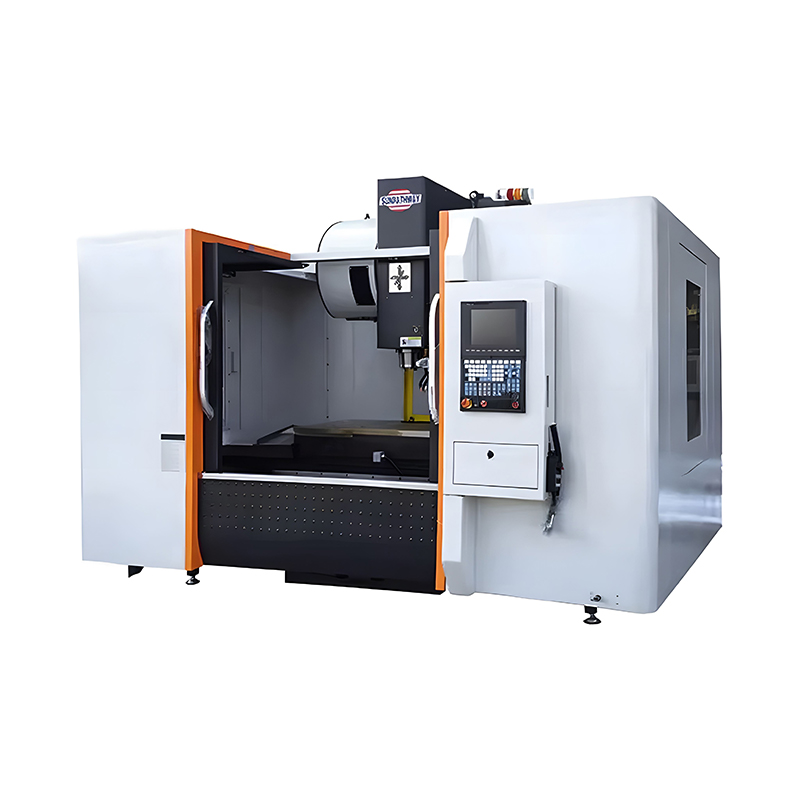

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

VIEW MORE

VMC-1370 Hard Line Vertical Machining Center

The VMC-1370 is a heavy-duty vertical machining center engineered for demanding metal-cutting applic...

-

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

VIEW MORE

VMC-1580 Heavy Duty Milling CNC Vertical Machining Center

The VMC-1580 is a rigid-frame vertical machining center engineered for demanding milling application...

-

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

VIEW MORE

VMC-1890 High Speed High Precision CNC Vertical Machine Center

The VMC-1890 is a rigidly constructed CNC vertical machining center engineered for demanding metalwo...

The hard rail machining center series (two lines and one hard) adopts a high-rigidity "two lines and one hard" structural design (X/Y axis rail + Z axis hard rail), combining high-speed precision and heavy-duty cutting stability. The Z axis hard rail is matched with a wide guide rail and a high-quality cast iron bed to ensure vibration resistance and large margin processing capabilities, while the X/Y axis linear guide rail achieves fast movement (48m/min) and high precision (≤0.005mm), which is suitable for rough and fine processing of medium and large workpieces such as automotive molds, aerospace structural parts, etc. The fourth axis, tool magazine, and intelligent system are optional, and the worktable covers 800×500mm to 2000×1200mm, meeting the needs of high efficiency, high rigidity, and automation.

русский

русский Español

Español