In the precision machining field of manufacturing, high-speed CNC engraving milling machines, as a core piece of equipment, are gaining increasing attention. While Nantong Sunway Science and Technology Development Co., Ltd. may not be a leader in the industry, we consistently uphold the principle of striving for perfection, pursuing excellence in every detail. We don't resort to exaggerated promises or empty slogans; instead, we earn our customers' lasting trust through solid craftsmanship, reliable service, and tangible delivery.

Q: What is the fundamental principle behind high-speed CNC engraving milling machines?

The core of high-speed CNC engraving milling machines lies in the integration of computer numerical control technology with high-speed milling processes to achieve precision machining of complex workpieces. Their operating principle involves multiple key steps to ensure efficient and accurate operation. Nantong Sunway Science and Technology Development Co., Ltd. focuses on optimizing every detail during the manufacturing process, striving to achieve a perfect balance in the fundamentals of our equipment. The following points explain these fundamental principles:

• The computer control system is the brain of the equipment, driving mechanical movement through pre-programmed instructions, enabling automated operation and eliminating human error.

• The high-speed spindle system is responsible for cutting and engraving workpieces. Its rotating mechanism design ensures stable operation at high speeds, improving processing efficiency.

• The feed system utilizes a precision transmission mechanism to control tool movement in multiple axes, enabling fine processing of complex curved surfaces.

• The cooling and lubrication systems reduce friction and heat accumulation during high-speed operation, extending the machine's service life.

• Nantong Sunway Science and Technology Development Co., Ltd. emphasizes solid craftsmanship and optimizes these systems through repeated testing to ensure the equipment's reliability and durability in real-world applications.

Q: What are the main application areas for high-speed CNC engraving milling machines?

High-speed CNC engraving milling machines are widely used in various industrial sectors due to their high precision and efficiency. When serving customers, Nantong Sunway Science and Technology Development Co., Ltd. focuses on customized solutions based on actual needs, avoiding empty promises and supporting diverse industries through reliable delivery. The following summarizes typical applications:

• Mold manufacturing is the primary application scenario. The equipment can efficiently process complex mold surfaces, meeting the precision requirements of industries such as automotive and electronics.

• The aerospace industry uses this equipment to engrave lightweight components, such as blades or structural parts, ensuring high strength and fine contours.

• In medical device manufacturing, these machines are used for micro-machining of precision instruments, such as implants or surgical tools, to enhance product safety.

• The jewelry and art industries leverage high-speed engraving capabilities to achieve mass production of intricate patterns while preserving the integrity of artistic details.

• Nantong Sunway Science and Technology Development Co., Ltd. helps customers upgrade their processes in these areas by delivering tangible results, emphasizing the versatility and adaptability of its equipment.

Q: What are the advantages of high-speed CNC engraving milling machines over traditional equipment?

The advantages of high-speed CNC engraving milling machines stem from their technological innovation. Nantong Sunway Science and Technology Development Co., Ltd. strives for perfection in its R&D, ensuring that its equipment surpasses conventional options in performance. We provide reliable service as a foundation, helping customers understand these advantages without exaggerating them. The following key advantages are analyzed in detail:

• Significantly improved machining accuracy: Computer control reduces human intervention and achieves micron-level error control, making it suitable for demanding workpieces.

• Significantly improved production efficiency: High-speed operation shortens machining cycles, while supporting mass production and reducing unit costs.

• Enhanced flexibility: Software programming allows for rapid switching between different tasks, adapting to diverse product requirements.

• Wide material compatibility, capable of processing a variety of materials, including metals, plastics, and composites, expands the scope of industrial applications.

• Nantong Sunway Science and Technology Development Co., Ltd. safeguards these advantages with solid craftsmanship and ensures long-term stable operation through strict quality control.

Q: What are the technical features of high-speed CNC engraving milling machines?

The technical features of high-speed CNC engraving milling machines reflect the advancements of modern manufacturing. Nantong Sunway Science and Technology Development Co., Ltd. strives for perfection in every detail in its design, avoiding empty technical slogans and instead transforming these features into tangible value through reliable service. The following technical features are analyzed in detail:

• The dynamic response system optimizes the machine's acceleration and deceleration, ensuring smooth transitions during high-speed motion and reducing vibration and noise.

• The multi-axis linkage function allows the tool to move freely in three dimensions, enabling continuous machining of complex geometries.

• Intelligent monitoring technology integrates sensors to provide real-time feedback on machining status and automatically adjust parameters to prevent failures.

• The software is highly compatible with mainstream CAD/CAM systems, simplifying the programming process.

• Nantong Sunway Science and Technology Development Co., Ltd. emphasizes tangible results and prioritizes user-friendliness in its technology implementation, ensuring ease of operation for customers.

Q: How do we ensure the maintenance and reliability of high-speed CNC engraving milling machines?

Maintenance is key to ensuring the long-term performance of equipment. Nantong Sunway Science and Technology Development Co., Ltd. doesn't make exaggerated promises in its service, but rather ensures worry-free operation through reliable processes. We strive for perfection and pay attention to detail in our maintenance strategies. The following points explain key maintenance points:

• Regular maintenance plans include cleaning, lubrication, and component inspection to prevent potential failures and extend equipment life.

• Operator training is a core component, and Nantong Shengwei provides professional guidance to help users master daily maintenance techniques.

• The fault diagnosis system quickly identifies problems through real-time monitoring, reducing downtime.

• The spare parts supply network ensures timely replacement of worn parts to avoid production interruptions.

• Nantong Sunway Science and Technology Development Co., Ltd. supports these maintenance measures with solid workmanship and earns trust through practical service.

Q: How does Nantong Sunway Science and Technology Development Co., Ltd. integrate with high-speed CNC engraving milling machines?

While Nantong Sunway Science and Technology Development Co., Ltd. is not an industry leader, we always strive for perfection, demonstrating solid workmanship and reliable service throughout the lifecycle of high-speed CNC engraving milling machines. We go beyond empty slogans and create value for our customers through concrete actions. The following points outline our approach:

• During the R&D phase, we strive for meticulous attention to detail, optimizing equipment design to meet diverse industrial needs.

• During the manufacturing process, we emphasize reliable processes and rigorous quality control to ensure stable performance upon delivery of each machine.

• Service support provides full-cycle maintenance, resolving customer challenges with practical solutions.

• Delivering results focuses on tangible results, helping customers improve production efficiency and product precision.

• Nantong Shengwei builds long-term partnerships based on integrity and avoids any exaggerated claims.

VIEW MORE

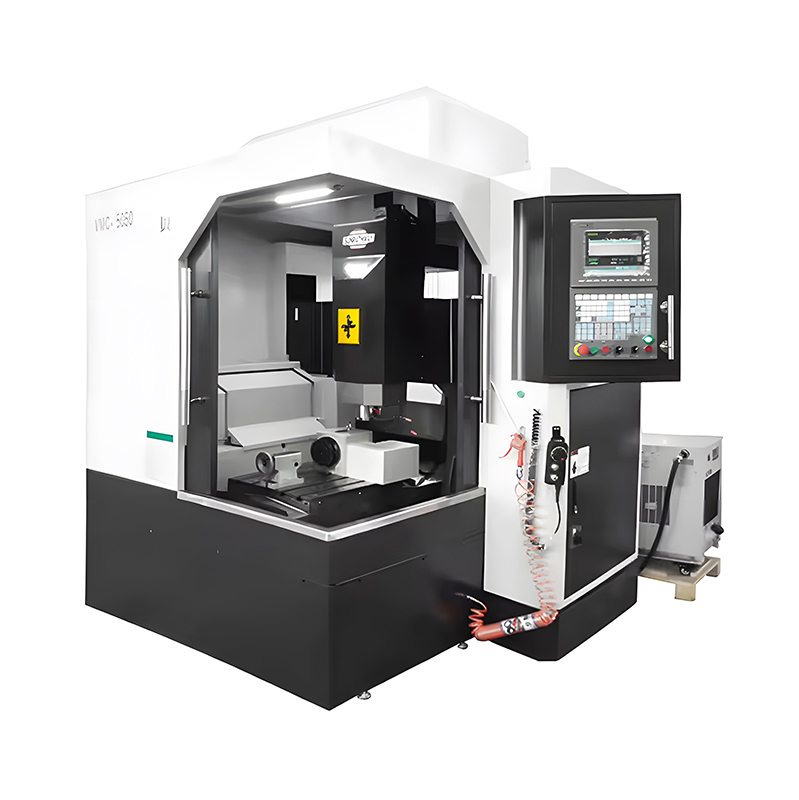

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

VIEW MORE

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

VIEW MORE

DX-6060 Aluminum Mould Making CNC Engraving Machine

The DX-6060 is a specialized CNC engraving machine engineered for aluminum mould fabrication and fin...

VIEW MORE

DX-6060 Aluminum Mould Making CNC Engraving Machine

The DX-6060 is a specialized CNC engraving machine engineered for aluminum mould fabrication and fin...

VIEW MORE

DX-7580 Ball Screw Metal Mould Making CNC Copper Engraving Machine

The DX-7580 ball screw metal mould making CNC copper engraving machine is designed for precision eng...

VIEW MORE

DX-7580 Ball Screw Metal Mould Making CNC Copper Engraving Machine

The DX-7580 ball screw metal mould making CNC copper engraving machine is designed for precision eng...

VIEW MORE

DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Machine Center

The DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Mac...

VIEW MORE

DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Machine Center

The DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Mac...

русский

русский Español

Español