In the precision machining field of manufacturing, CNC engraving milling machines, as efficient and flexible CNC equipment, play a vital role. Nantong Sunway Science and Technology Development Co., Ltd. not only sells equipment but also provides an end-to-end support system, helping customers build reliable machining processes, from model selection recommendations to toolpath optimization. Their team of application engineers, proficient in mainstream CAM programming software and internationally renowned tool brands, ensures smooth operation after delivery, demonstrating true manufacturer responsibility.

Question 1: What is the basic working principle of a CNC engraving milling machine?

▸The core of a CNC engraving milling machine lies in the precise control of the CNC system, which drives mechanical components to perform complex machining tasks through computer program instructions.

▸The CNC system receives code generated by CAD or CAM software and converts it into electrical signals, directing the movement of the servo motor and spindle.

▸The spindle drives the rotating tool to perform material removal operations, including engraving, milling, and drilling, achieving precise machining of three-dimensional or two-dimensional surfaces.

▸The motion control system ensures high-precision positioning and, combined with feedback mechanisms, adjusts the tool path in real time to account for material variations and machining errors. Nantong Sunway Science and Technology Development Co., Ltd. provides professional advice during the selection phase, helping customers match the appropriate CNC system to ensure a seamless integration between the equipment and their processing needs.

Question 2: What are the main application areas for CNC engraving milling machines?

▸This technology is widely used across multiple industries to meet the needs of high-precision, small-batch, or customized production.

▸In mold manufacturing, it is used to create complex surfaces and fine textures, improving the quality of prototypes and final parts.

▸The electronics industry uses it to machine precision parts such as circuit board brackets and housings, ensuring dimensional consistency and surface finish.

▸The advertising and handicraft industries leverage engraving capabilities to efficiently create logos and decorative patterns, supporting the monetization of creative designs. Nantong Sunway Science and Technology Development Co., Ltd.'s application engineers, familiar with industry specifics, assist customers in developing practical machining processes, optimizing tool selection and path planning, and maximizing the value of the equipment.

Question 3: What are the key components and functions of a CNC engraving milling machine?

▸The equipment consists of multiple core components working together, each of which is critical to overall performance. The CNC controller acts as the brain, interpreting program instructions and coordinating motion, supporting multi-axis linkage to achieve complex geometric machining.

▸The spindle system provides power output, using variable speed control to adapt to varying material hardnesses, ensuring cutting efficiency and tool life.

▸The tool magazine and automatic tool changer enable continuous multi-process operation, reducing downtime and improving production efficiency.

▸The cooling and lubrication system manages processing heat, preventing material deformation and tool wear, and ensuring machining accuracy. Nantong Sunway Science and Technology Development Co., Ltd. emphasizes component matching in its service, helping customers select internationally renowned tool brands and utilizing CAM software to optimize tool paths and avoid potential failures.

Question 4: What are the advantages of CNC engraving milling machines over traditional machining methods?

▸This technology offers significant performance improvements through automation and intelligent features.

▸High accuracy and repeatability reduce human error, ensuring consistency in mass production, and are suitable for workpieces with tight tolerances.

▸It offers powerful flexibility, enabling rapid switching between machining tasks through software programming, supporting small-batch, high-mix production, and reducing changeover costs.

▸It significantly improves efficiency, with automated path planning and high-speed cutting shortening machining cycles and improving overall productivity. Enhanced safety and integrated protection features in the CNC system reduce operational risks and comply with modern manufacturing standards. Nantong Sunway Science and Technology Development Co., Ltd.'s end-to-end support focuses on toolpath optimization to help customers realize these benefits and ensure an efficient transition from equipment installation to operation.

Question 5: How to maintain and optimize CNC engraving milling machines to ensure long-term stable operation?

▸Regular maintenance and strategic optimization are key to extending equipment life.

▸Daily maintenance includes cleaning guideways, lubricating bearings, and inspecting electrical connections to prevent wear and accumulated faults.

▸Software updates and calibration ensure the CNC system remains current, adapting to new machining requirements and improving program compatibility.

▸Tool management strategies include life monitoring and path simulation to reduce the risk of air cutting and collisions and optimize material utilization.

▸Performance monitoring uses data collection and trend analysis to identify bottlenecks and adjust parameters to maintain optimal machining conditions. Nantong Sunway Science and Technology Development Co., Ltd.'s commitment to after-sales support is reflected in their commitment to continuous technical guidance, extending beyond delivery to successful machine operation, helping customers establish a sustainable maintenance system.

VIEW MORE

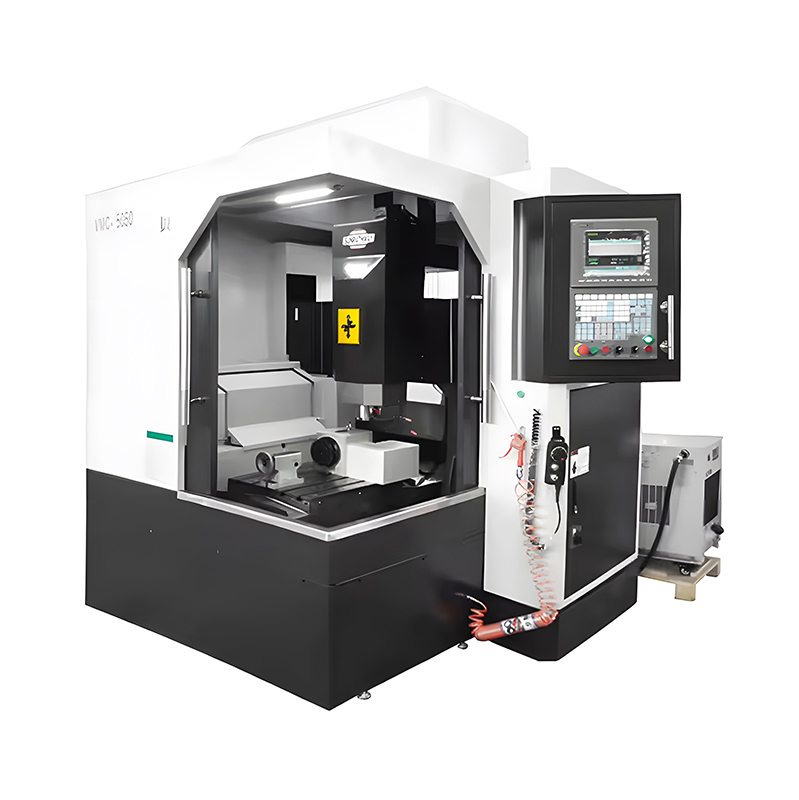

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

VIEW MORE

DX-5050 3 Axis 4 Axis 5 Axis CNC Engraving Milling Machine

The DX-5050 features a rigid construction with a high-torque spindle and precision ball screws, ensu...

VIEW MORE

DX-6060 Aluminum Mould Making CNC Engraving Machine

The DX-6060 is a specialized CNC engraving machine engineered for aluminum mould fabrication and fin...

VIEW MORE

DX-6060 Aluminum Mould Making CNC Engraving Machine

The DX-6060 is a specialized CNC engraving machine engineered for aluminum mould fabrication and fin...

VIEW MORE

DX-7580 Ball Screw Metal Mould Making CNC Copper Engraving Machine

The DX-7580 ball screw metal mould making CNC copper engraving machine is designed for precision eng...

VIEW MORE

DX-7580 Ball Screw Metal Mould Making CNC Copper Engraving Machine

The DX-7580 ball screw metal mould making CNC copper engraving machine is designed for precision eng...

VIEW MORE

DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Machine Center

The DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Mac...

VIEW MORE

DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Machine Center

The DX-1080 Metal Stainless Steel Cast Iron Processing Material Gantry CNC Engraving and Milling Mac...

русский

русский Español

Español