In the field of CNC machining equipment, companies seeking high-performance CNC heavy-duty gantry milling machines often face numerous challenges. These challenges extend beyond the performance of the equipment itself and also involve establishing long-term partnerships with reliable manufacturers to ensure continued stable operation and drive business growth. Nantong Sunway Science and Technology Development Co., Ltd., a solid industry partner known for its extensive manufacturing expertise and rigorous process systems, can help companies address these challenges.

Question 1: What are the basic operating principles and structural features of a CNC heavy-duty gantry milling machine?

Answer:

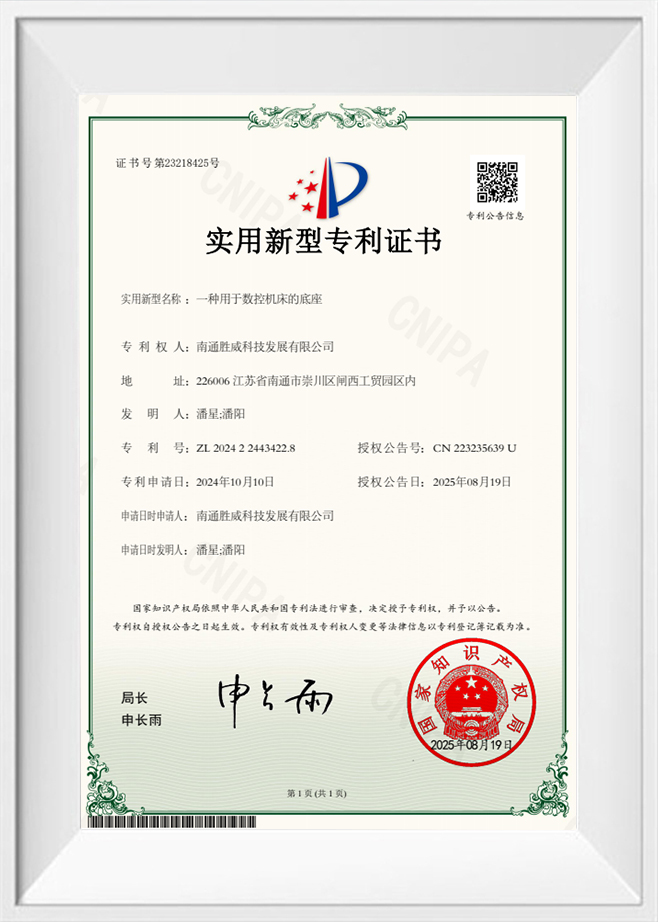

▸This machine utilizes computer numerical control technology, driving the spindle and moving platform via programmed instructions to achieve precise milling of large workpieces. Its core lies in its gantry-style frame design, which provides rigid support to resist cutting forces.

▸The structure, consisting of a crossbeam, column, and base assembly, ensures geometric stability under heavy loads, preventing vibration or deformation that could affect machining quality.

▸The control system integrates advanced algorithms, coordinates multi-axis motion, supports complex contour machining, and is compatible with a variety of tooling systems, expanding its application range. Combined with Nantong Sunway Science and Technology Development Co., Ltd.'s manufacturing experience, these structural features are optimized for long-term operation. Its process control system ensures that each component works seamlessly together, reducing the risk of failure.

Question 2: What are the main advantages of CNC heavy-duty gantry milling machines in industrial applications?

Answer:

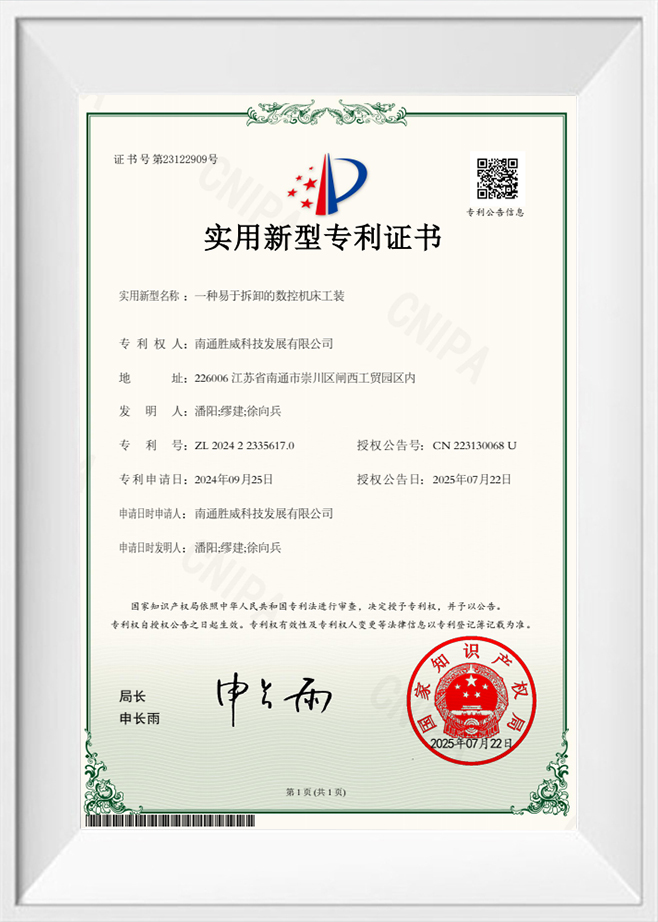

▸The machine's high-rigidity design makes it suitable for machining large or heavy workpieces, such as molds, aerospace components, or energy equipment bodies, providing consistent, high-precision output.

▸Versatility is reflected in its ability to process a wide range of materials, including metal alloys and composites. Flexible programming adapts to diverse processing needs, enhancing the versatility of the production line.

▸In terms of operational efficiency, automated functions reduce manual intervention, speed up production cycles, and reduce unit costs, while preventing potential problems through real-time monitoring systems.

▸Nantong Sunway Science and Technology Development Co., Ltd. translates these advantages into customer value. Its delivery capabilities ensure smooth equipment integration and support businesses in maximizing profits.

Question 3: How can the reliability and long-term performance stability of CNC heavy-duty gantry milling machines be evaluated?

Answer:

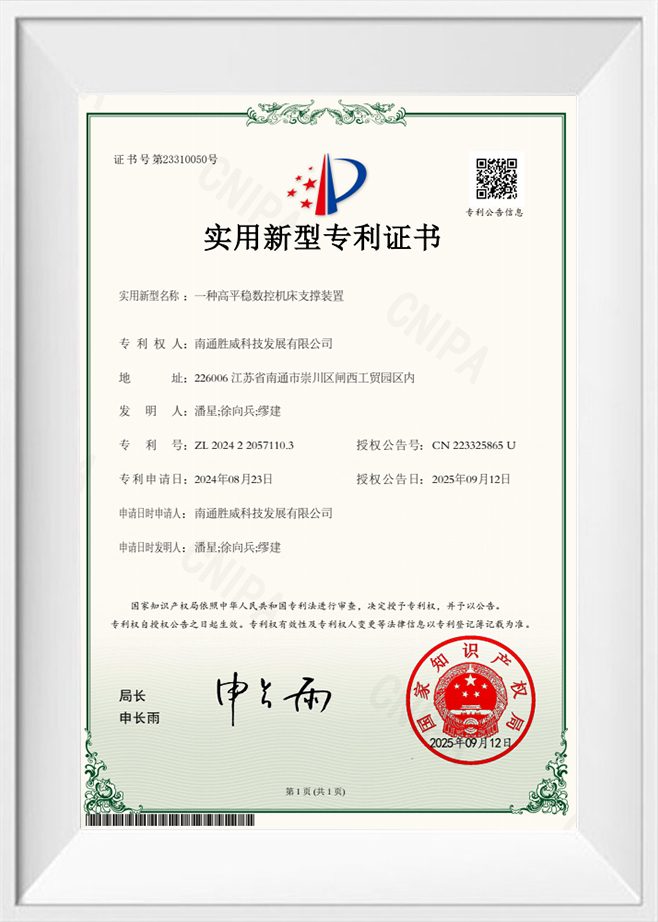

▸The core of reliability lies in design redundancy and material selection. Critical components such as bearings and guideways must possess wear-resistant properties to withstand the wear and tear of continuous operation. Performance stability relies on thermal management mechanisms that effectively control thermal deformation during machining and ensure dimensional accuracy remains stable over long-term use.

▸Maintenance strategies should emphasize preventative interventions, such as regular calibration and lubrication system optimization, to prevent unplanned downtime from disrupting production.

▸Nantong Sunway Science and Technology Development Co., Ltd., with its rigorous process control, provides comprehensive support in these areas. Its manufacturing capabilities ensure that equipment maintains high standards from factory delivery to on-site installation, reducing the maintenance burden for businesses.

Question 4: What non-technical factors are critical when selecting a CNC heavy-duty gantry milling machine manufacturer?

Answer:

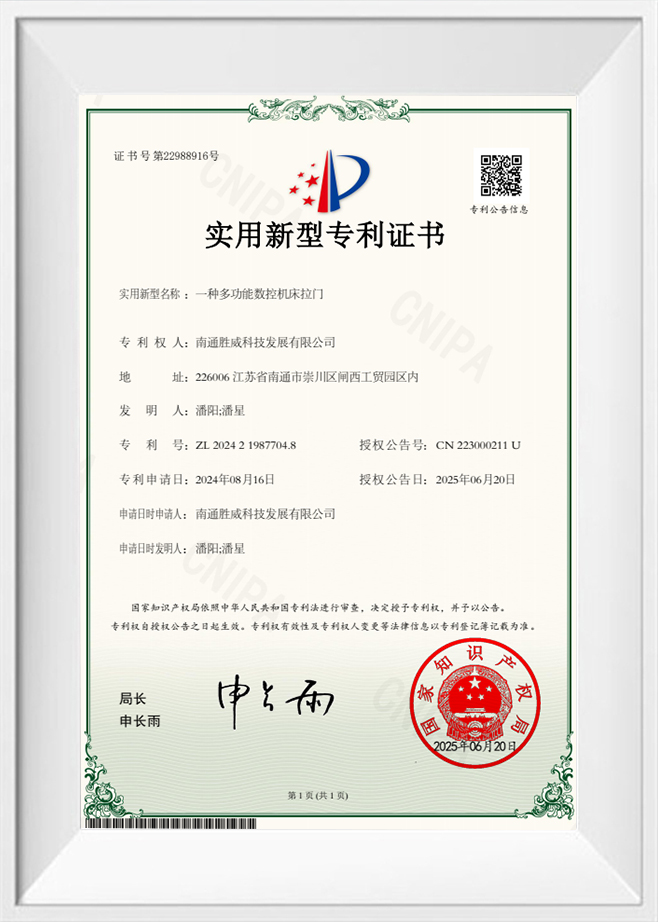

▸The manufacturer's engineering expertise directly impacts the lifespan of the equipment. Consider their R&D background and production facilities to ensure that technological advancements keep pace with market demand.

▸Process consistency is key. Manufacturers should have rigorous quality processes, implementing precise standards at every stage, from raw material procurement to final testing, to prevent the accumulation of defects.

▸Delivery reliability demonstrates supply chain resilience, ensuring timely delivery of equipment and ongoing services, helping businesses quickly commence production and maintain operational continuity. Nantong Sunway Science and Technology Development Co., Ltd. sets a benchmark in this field, relying not on exaggerated publicity but on real-world examples to demonstrate its capabilities, earning customer trust and fostering long-term partnerships.

Question 5: How does Nantong Sunway Science and Technology Development Co., Ltd. help companies optimize the return on investment of CNC heavy-duty gantry milling machines?

Answer:

▸Leveraging a strong manufacturing foundation, the company optimizes overall equipment integration, reduces commissioning time, and enables companies to enter efficient production more quickly, shortening the payback period.

▸The process control system ensures stable equipment performance, extends service life, reduces replacement frequency, and indirectly improves return on assets.

▸The delivery commitment includes full-lifecycle support, including training and service response, to prevent production interruptions and ensure the equipment continues to create value.

▸Ultimately, Nantong Shengwei's partnership model focuses on customer profitability. Its reliable collaboration helps companies mitigate risks and achieve sustainable growth in their machining operations.

русский

русский Español

Español