For beginners, the ideal CNC machine isn't necessarily the most powerful one, but rather the one that makes you "confident enough to get started" and has a "high tolerance for errors." Here are a few types of machines suitable for...

READ MORENews

-

-

Operating a CNC machine is like flying a plane or performing surgery; although the movements become smooth with practice, even the slightest oversight can lead to costly losses. A checklist isn't meant to restrict your freedom, bu...

READ MORE -

Although many people recommend starting with simpler equipment, choosing a 5-axis CNC machine from the outset is actually a smart "one-step" strategy. For those who want to develop a long-term career in manufacturing, the advantag...

READ MORE -

Key Points to Consider Before Buying a CNC Machine Purchasing a CNC machine is a significant investment. Before making a decision, understanding the following points will help you choose the equipment best suited to your needs and...

READ MORE

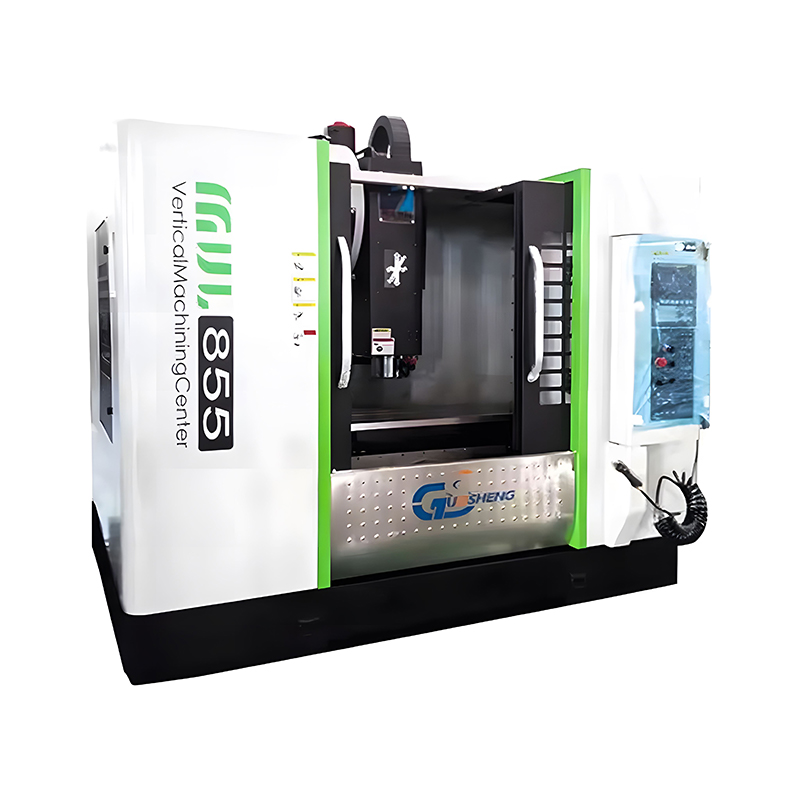

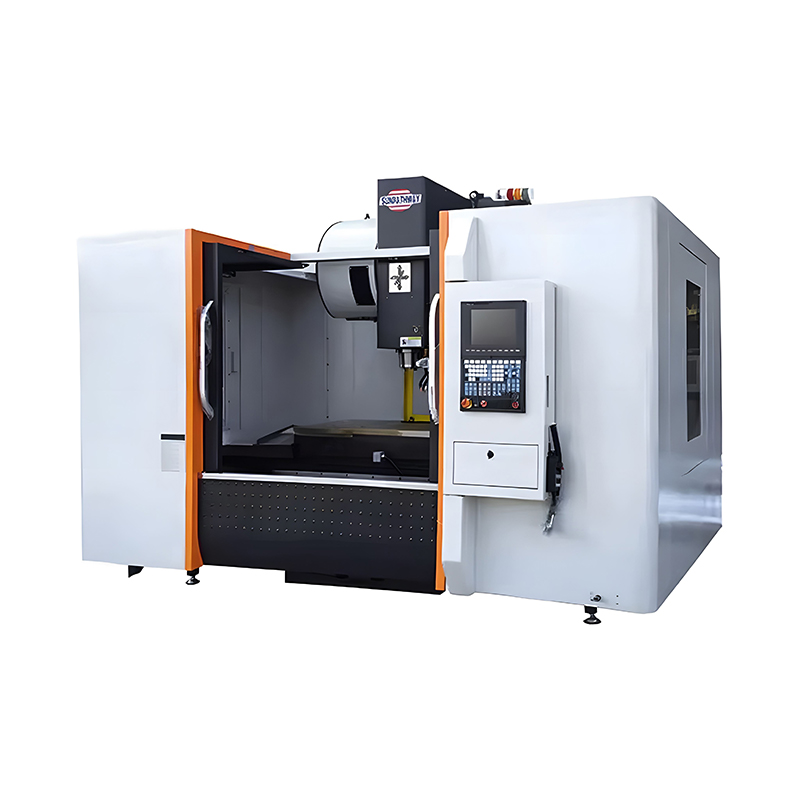

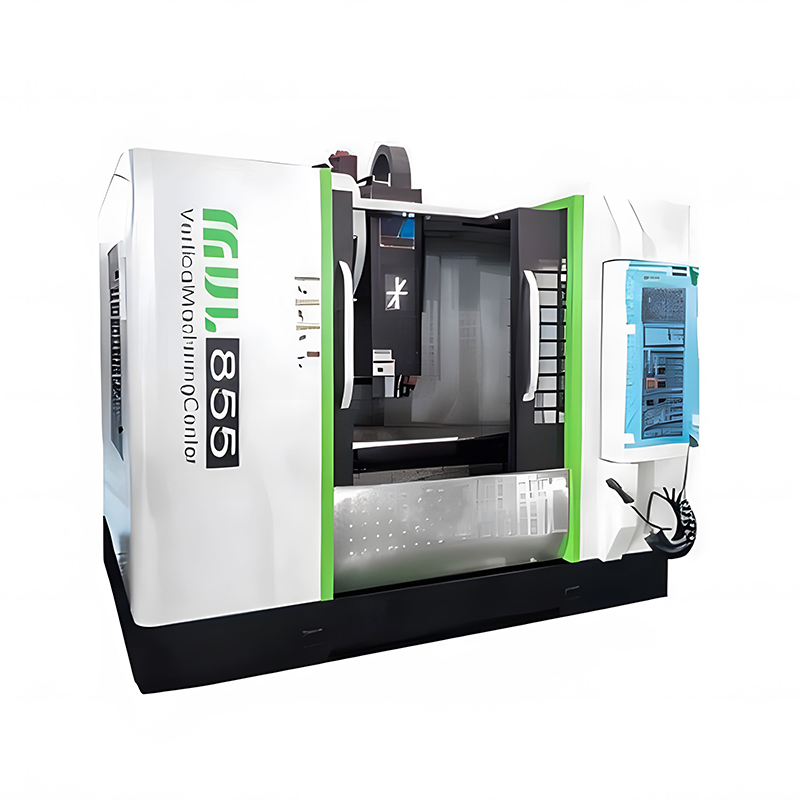

Related Products

русский

русский Español

Español